Preparation method for rubber and plastic reinforcing agent with adsorption function

A technology of reinforcing agent, rubber and plastic, applied in the field of elastomer reinforcing agent and its preparation, can solve the problems of harm to user's health, environmental pollution, and high cost of rubber and plastic products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

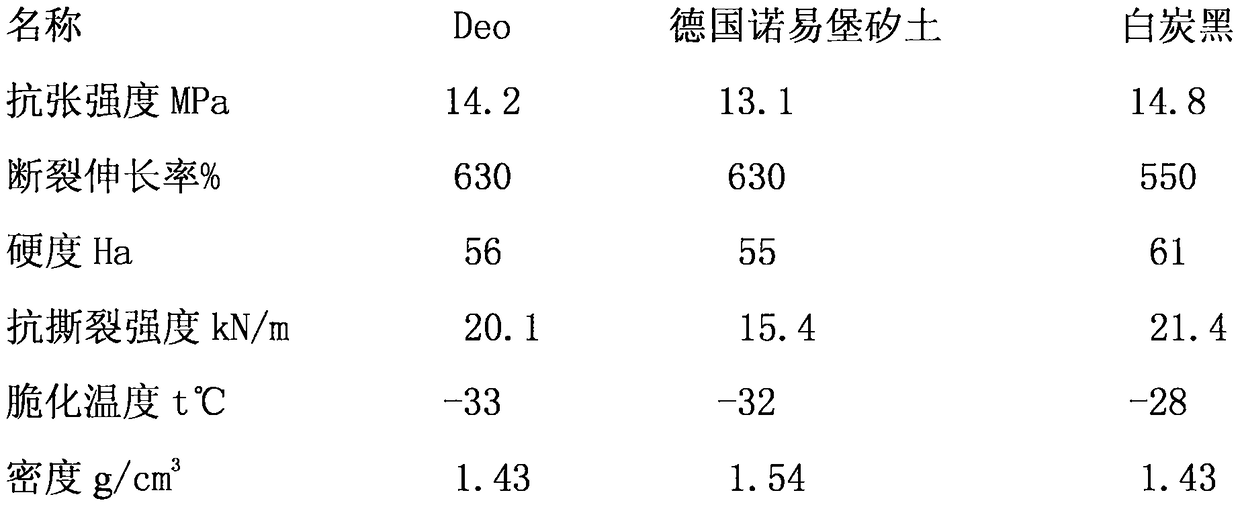

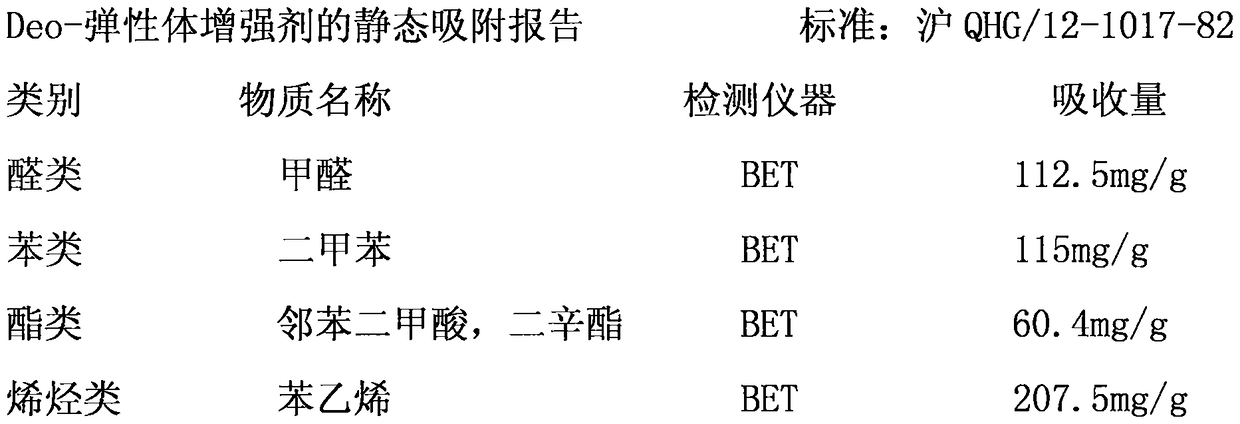

[0042] Product name: Deo-elastomer reinforcement

[0043] formula:

[0044] Opal Ore: 40%;

[0045] Clinoptilolite ore: 50%;

[0046] Mixing aids: oleic acid amide, industrial grade, 2%; zinc stearate, industrial grade, 3%; titanate, industrial grade, 2%;

[0047] Coupling agent; 3-aminopropyltrimethoxysilane, technical grade, 3%;

[0048] Formula unit is weight percent;

[0049] preparation

[0050] Preparation conditions, equipment:

[0051] Ambient air pressure: one atmosphere

[0052] Ambient temperature: room temperature

[0053] Main preparation equipment: continuous water mill, spray drying tower, calcining rotary kiln, jaw crusher, screw conveyor, storage tank, high-speed mixer;

[0054] The preparation process is crushing, pulping, drying, calcining, dispersing and mixing modification;

[0055] Step 1. Broken

[0056] The opal ore and clinoptilolite ore in the formula are crushed and processed into 30-50mm blocks with a jaw crusher, respectively, to obtain o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com