Polyurethane type oil-resistant sealant as well as preparation method and application thereof

A polyurethane and sealant technology, applied in the field of sealants, can solve problems such as inability to overcome component migration, and achieve the effects of promoting good compatibility, reducing mobility and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

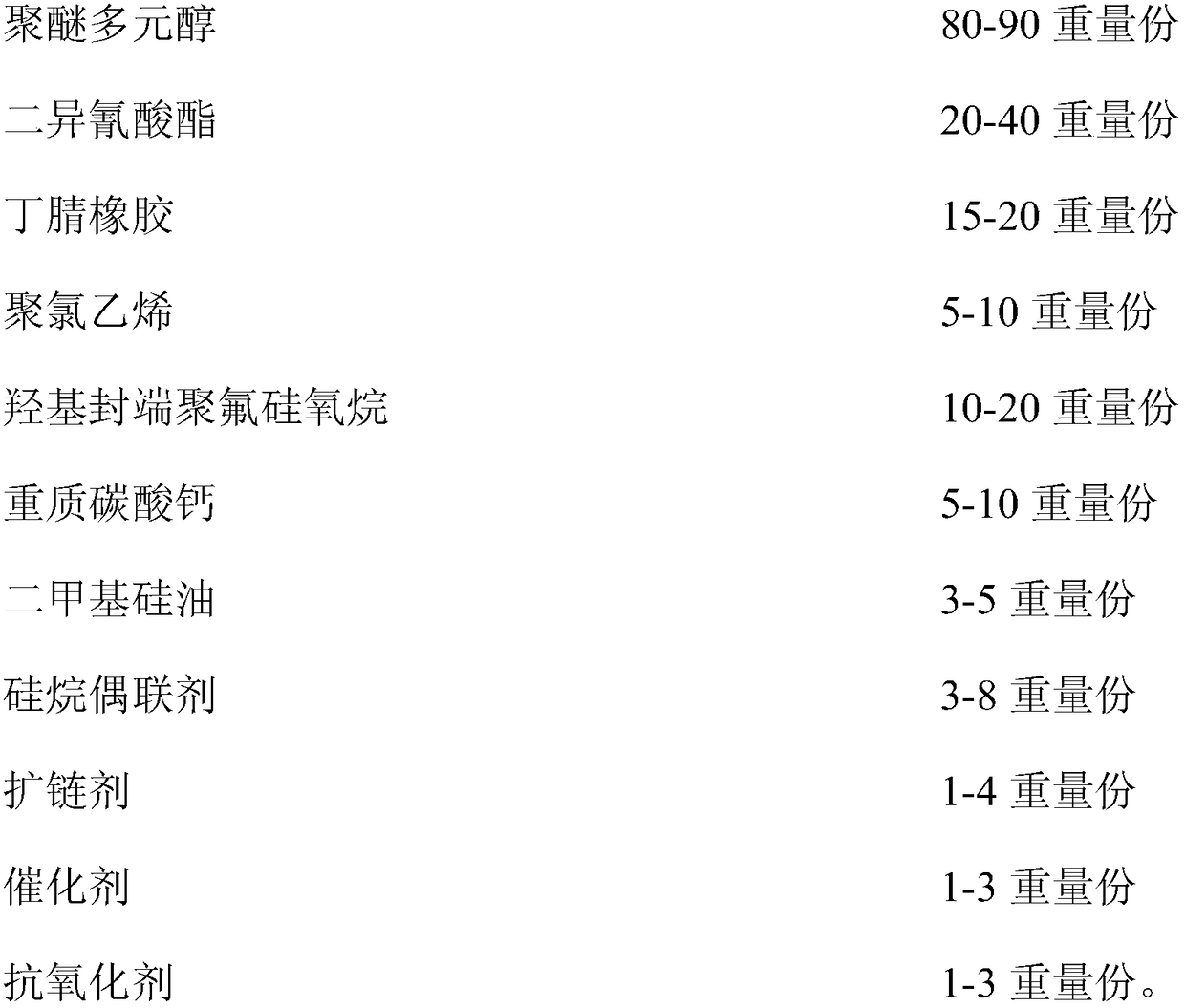

[0042] In this embodiment, the raw materials for the preparation of polyurethane oil-resistant sealant include the following components by weight:

[0043]

[0044] Wherein, the diisocyanate is a mixture of dimethyl biphenyl diisocyanate and p-phenylene diisocyanate with a mass ratio of 1:3, the silane coupling agent is a hexaalkoxysilane coupling agent, and the chain extender is 1,3 -Propylene glycol, the catalyst is dibutyltin dioctoate, and the antioxidant is antioxidant 264.

[0045] The preparation method comprises the following steps:

[0046] (1) Mix polyether polyol, diisocyanate, hydroxyl-terminated polyfluorosiloxane, chain extender, catalyst and antioxidant, and mix them under the condition of stirring at a speed of 90r / min at 80°C and a vacuum of -0.2kPa Vacuum dehydration under pressure, and then react at 120°C for 5h;

[0047] (2) Mix the product of step (1) with nitrile rubber, polyvinyl chloride, heavy calcium carbonate, dimethyl silicone oil and silane coup...

Embodiment 2

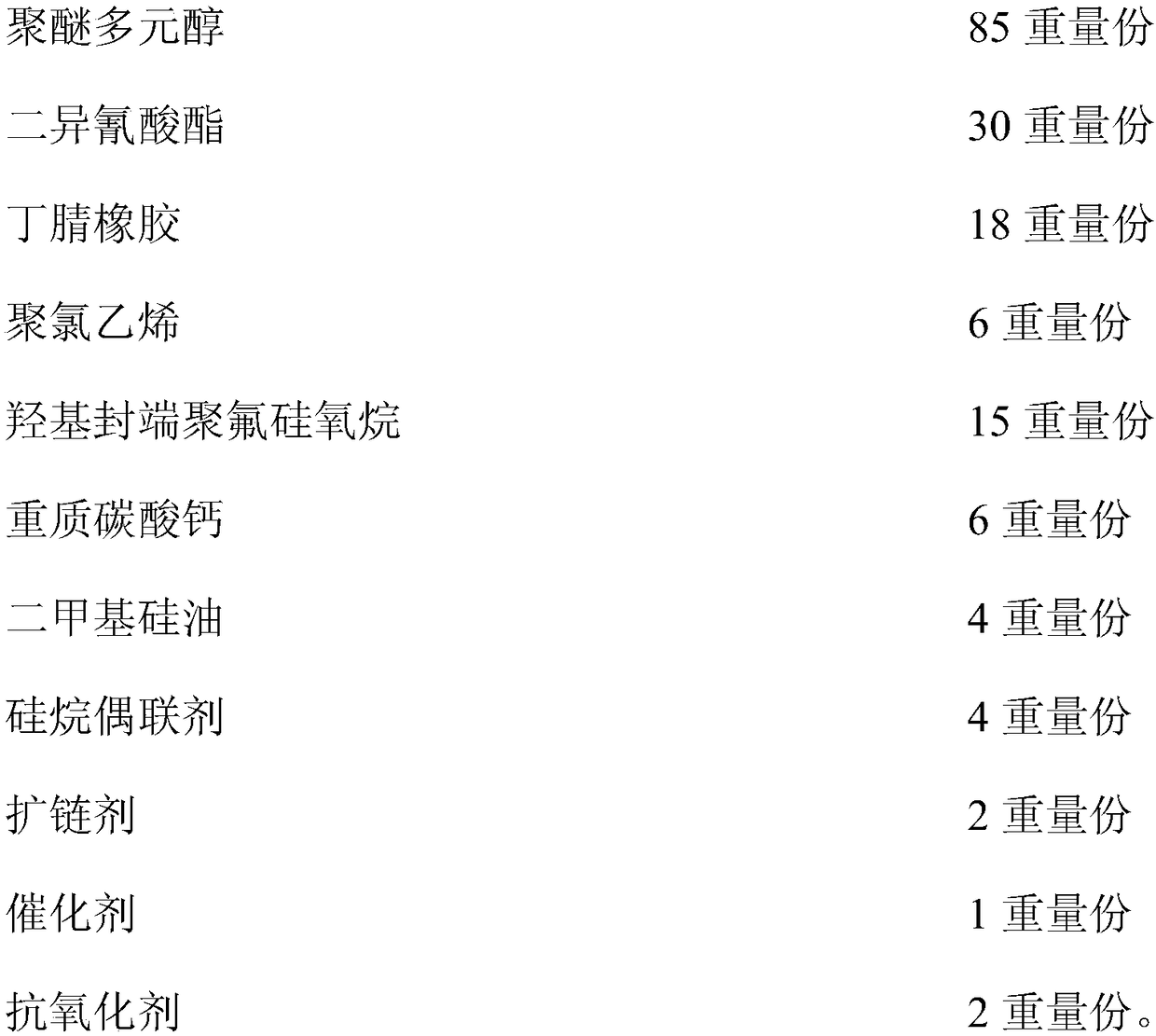

[0049] In this embodiment, the raw materials for the preparation of polyurethane oil-resistant sealant include the following components by weight:

[0050]

[0051] Wherein, the diisocyanate is a mixture of dimethyl biphenyl diisocyanate and p-phenylene diisocyanate with a mass ratio of 1:1, the silane coupling agent is a hexaalkoxysilane coupling agent, and the chain extender is ethylene glycol , the catalyst is dibutyltin laurate, and the antioxidant is antioxidant 1010.

[0052] The preparation method comprises the following steps:

[0053] (1) Mix polyether polyol, diisocyanate, hydroxyl-terminated polyfluorosiloxane, chain extender, catalyst and antioxidant, and mix them under a stirring condition of 100r / min at 90°C and a vacuum of -0.1kPa Vacuum dehydration under pressure, and then react at 130°C for 6h;

[0054] (2) Mix the product of step (1) with nitrile rubber, polyvinyl chloride, heavy calcium carbonate, simethicone oil and silane coupling agent, banbury at 80...

Embodiment 3

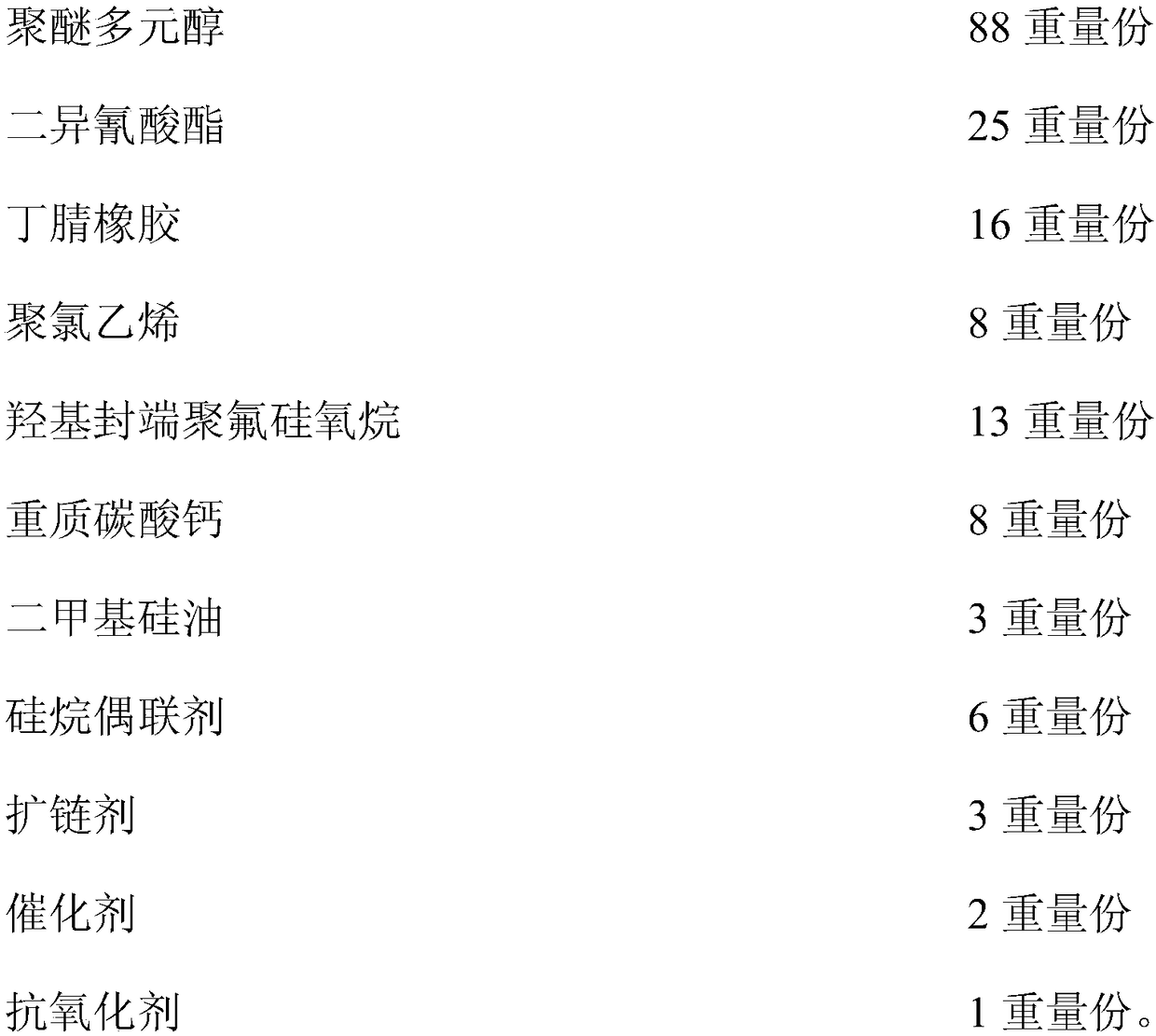

[0056] In this embodiment, the raw materials for the preparation of polyurethane oil-resistant sealant include the following components by weight:

[0057]

[0058] Wherein, the diisocyanate is a mixture of dimethyl biphenyl diisocyanate and p-phenylene diisocyanate with a mass ratio of 1:2, the silane coupling agent is a hexaalkoxysilane coupling agent, and the chain extender is 1,4 -butanediol, the catalyst is dibutyltin dioctoate, and the antioxidant is antioxidant TPP.

[0059] The preparation method comprises the following steps:

[0060] (1) Mix polyether polyol, diisocyanate, hydroxyl-terminated polyfluorosiloxane, chain extender, catalyst and antioxidant, and mix them under a stirring condition of 120r / min at 70°C and a vacuum of -0.3kPa Vacuum dehydration under pressure, and then react at 140°C for 3h;

[0061] (2) Mix the product of step (1) with nitrile rubber, polyvinyl chloride, heavy calcium carbonate, dimethyl silicone oil and silane coupling agent, banbury...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com