A kind of anionic nonionic surfactant heavy oil viscosity reducing oil displacement agent and its preparation method and application

A surfactant, anionic and nonionic technology, applied in the field of oil displacement agents, can solve the problems of low interfacial tension and emulsification viscosity reduction effect, residual organic chlorine, affecting crude oil refining, etc., and achieves good emulsification viscosity reduction effect and interfacial tension. low value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

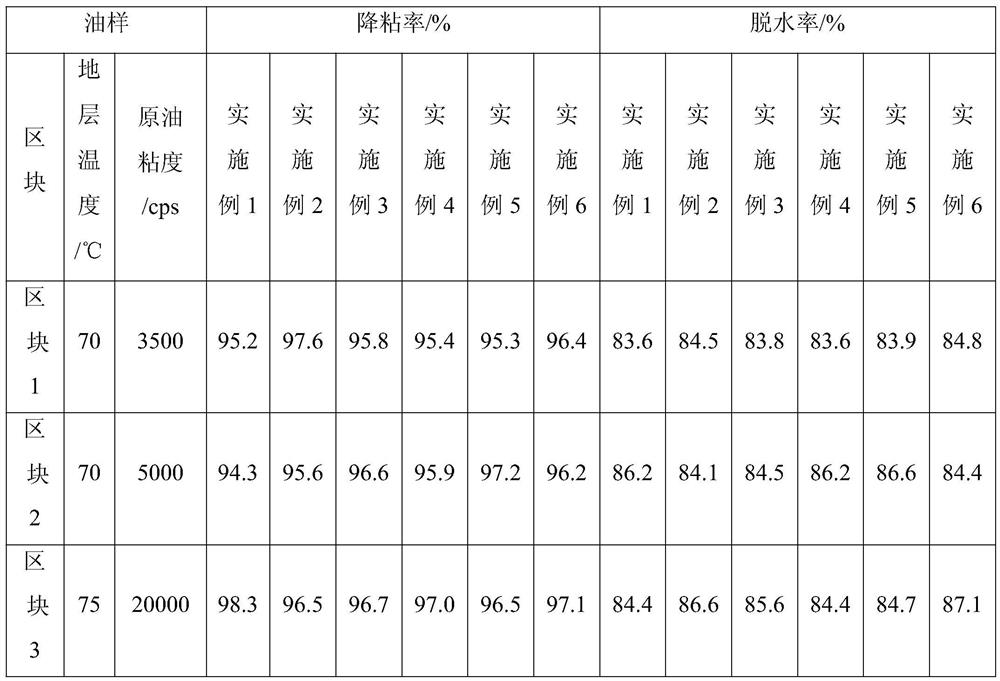

Examples

preparation example Construction

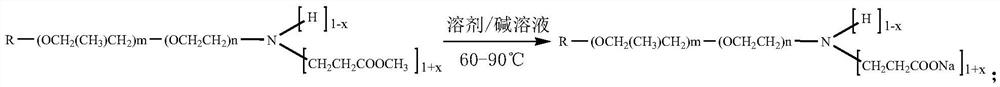

[0020] The preparation method of above-mentioned anionic nonionic surfactant heavy oil viscosity reducing oil displacement agent, comprises the following steps:

[0021] (a) Carry out Michael addition reaction of long-chain polyetheramine and methyl acrylate in a solvent at a molar ratio of 1:1 to 2 for 5-12 hours, the amount of solvent used is 20wt% of the total amount of reactants, and the solvent is methanol, ethanol, One or more of isopropanol, water,

[0022] (b) The product of the addition reaction is hydrolyzed for 5-12h in a sodium hydroxide solution with a mass fraction of 20-40%. The mol ratio of the product to sodium hydroxide is 1:1~2, and then V / V= Adjust the pH to 6.0-7.0 with 1:1 dilute sulfuric acid, add water to a solid content of 35%, and obtain a viscous oil displacement agent for heavy oil.

[0023] Among them, R is H 3 C-(CH 2 )y-, Or a mixture of the two, y=8-15; the value range of m is 0-10, the value range of n is 0-10, and the value range of x...

Embodiment 1

[0025] Add 20wt% of methanol in the three-necked flask, and add lauryl alcohol polyoxyethylene ether amine (4EO) and methyl acrylate at a molar ratio of 1:1, deoxygenate with nitrogen for 10 minutes, and start heating to 50°C. Addition reaction 5h;

[0026] The product of the addition reaction was hydrolyzed for 5 h in a sodium hydroxide solution with a mass fraction of 30%, the molar ratio of the product to sodium hydroxide was 1:1, and then the pH was adjusted to 6.5, add water to a solid content of 35%, and obtain a viscous oil displacement agent for heavy oil.

Embodiment 2

[0028] Add 20wt% ethanol accounting for the total amount of reactants in a three-necked flask, add nonylphenol polyvinyl ether amine (4EO) and methyl acrylate at a molar ratio of 1:2, blow nitrogen to remove oxygen for 10 minutes, and start heating to 50°C. Addition reaction 8h;

[0029] The product of the addition reaction was hydrolyzed for 10 h in a sodium hydroxide solution with a mass fraction of 35%, and the molar ratio of the product to sodium hydroxide was 1:1.5, and then the pH was adjusted to 7. Supplement water to a solid content of 35% to obtain a heavy oil viscosity reducing oil displacement agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dehydration rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com