High-temperature-resistant salt-tolerant naphthol derivative quaternary ammonium salt foaming agent as well as a preparation method and application thereof

A technology for naphthol derivatives and foaming agents, which is applied in the preparation of organic compounds, the preparation of carboxylic acid amides, chemical instruments and methods, etc., can solve the problems of short half-life, no foam performance, poor stability, etc., and achieves improved stability. , good foaming performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

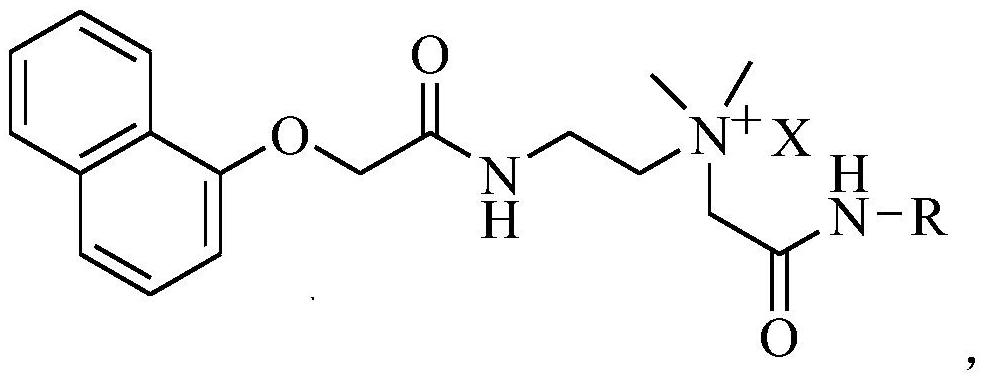

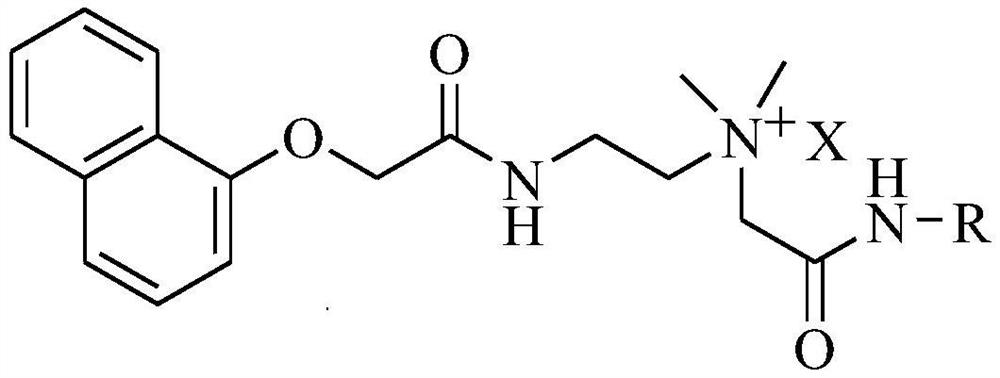

[0025] Specific embodiment one: the structural formula of the high-temperature and salt-resistant naphthol derivative quaternary ammonium salt foaming agent of the present embodiment is:

[0026]

[0027] where R=C n h 2n+1 , n=10, 12, 14, 16 or 18, X is halogen. Named FS-n.

specific Embodiment approach 2

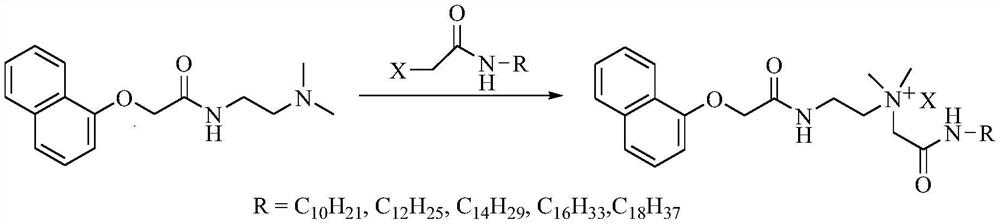

[0028] Specific embodiment two: the preparation method of the high-temperature and salt-resistant naphthol derivative quaternary ammonium salt foaming agent described in specific embodiment one, carry out according to the following steps:

[0029] 1. Add solvent I to the container, then add N-acetyl-(1-naphthyloxy)-N,N-dimethylethylenediamine and haloacetylalkylamine, wherein N-acetyl-(1 The molar ratio of -naphthyloxy)-N,N-dimethylethylenediamine to haloacetylalkylamine is 1:(1~6), heated to 100℃~160℃ and stirred for 20h~48h to obtain crude product;

[0030] 2. The crude product obtained in step 1 was rotary evaporated to obtain a white solid;

[0031] 3. After the white solid is recrystallized by solvent II, a high-temperature and salt-resistant naphthol derivative quaternary ammonium salt foam is obtained.

specific Embodiment approach 3

[0032] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the solvent I in step one is a mixed solution of acetonitrile and ethanol, a mixed solution of toluene and ethanol, a mixed solution of chloroform and water, methanol and dichloro A mixed solution of methane or petroleum ether; others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com