Hybrid energy control system and control method of solid oxide fuel cell

A technology of solid oxide and mixed energy, applied in the direction of fuel cell control, fuel cell, fuel cell additives, etc., can solve the problems of shortened working life of lithium batteries, reduced system efficiency, slow dynamic response of output power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

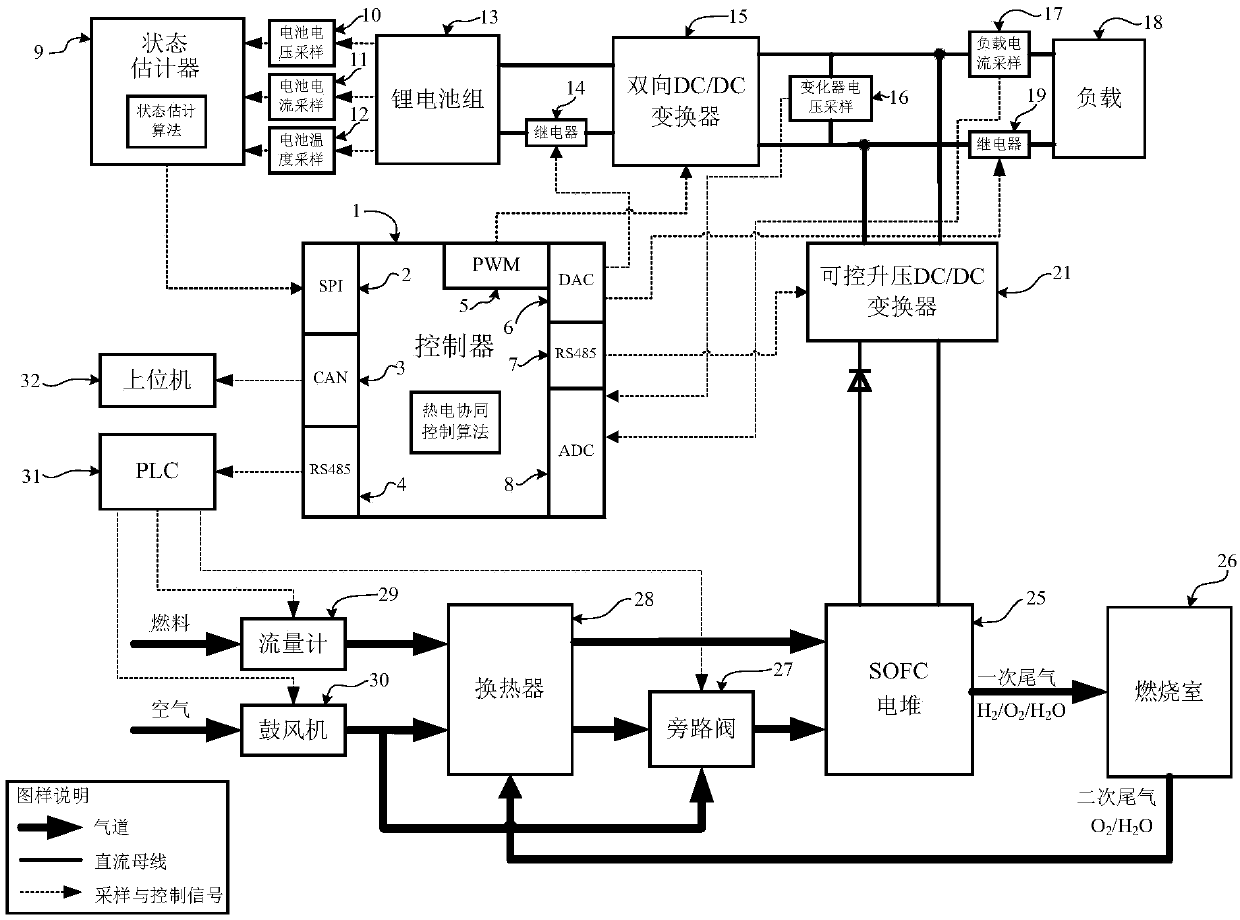

[0058] Such as figure 1 As shown, one embodiment of the present invention provides a hybrid energy control system for solid oxide fuel cells, the control system includes a controller 1, a state estimator 9, a bidirectional DC / DC converter 15, a controllable step-up DC / DC converter 21, PLC31, signal collector. The signal collector includes a battery temperature sampler 12 , a load current sampler 17 , a battery voltage sampler 10 , a converter voltage sampler 16 , and a battery current sampler 11 .

[0059] The input end and output end of the bidirectional DC / DC converter 15 are respectively connected to the lithium battery pack 13 and the load 18 via relays 14 and 19 . The input end and output end of the controllable step-up DC / DC converter 21 are respectively connected to the SOFC stack 25 and the DC bus. The load current sampler 17 detects the load current, and the converter voltage sampler 16 detects the output terminal voltage of the controllable step-up DC / DC converter...

Embodiment 2

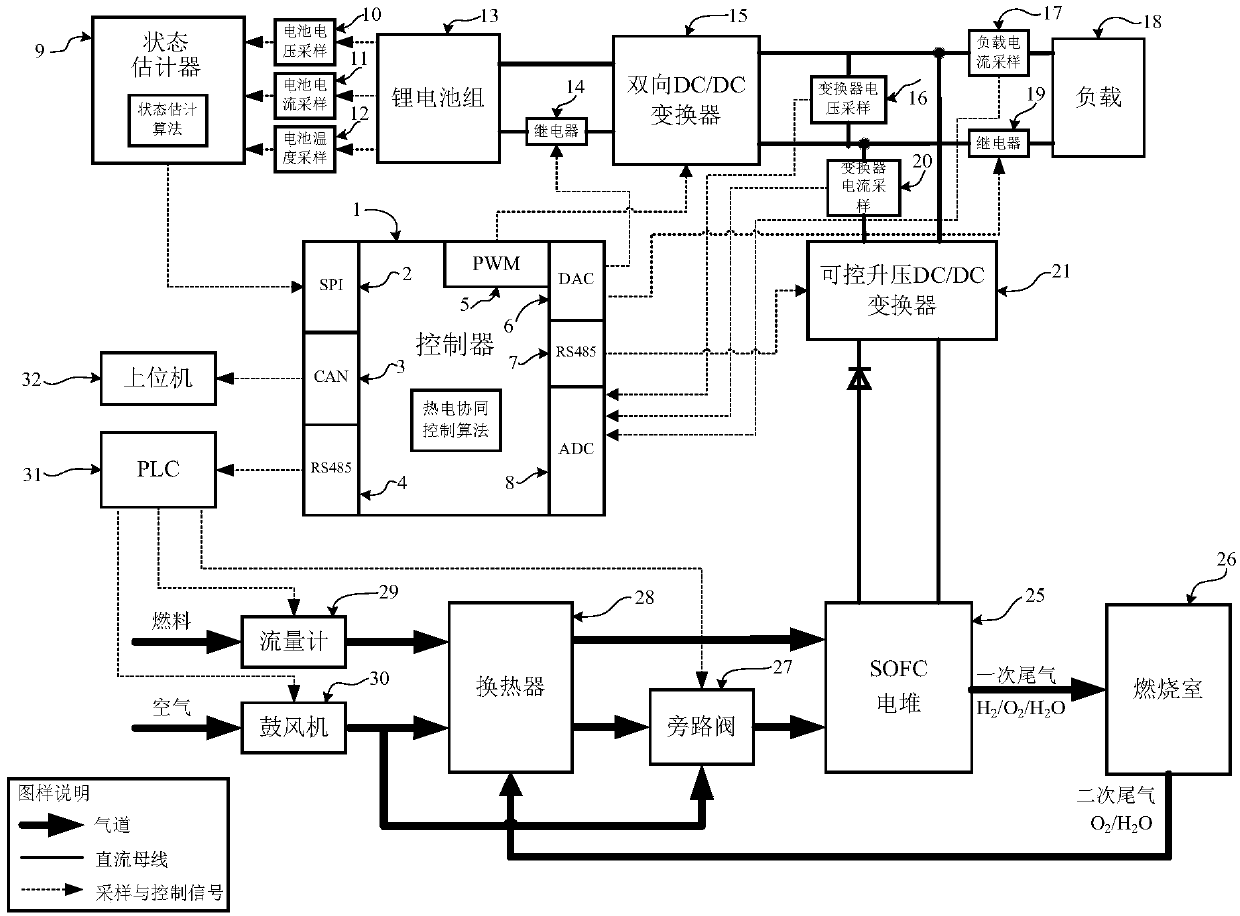

[0065] Such as figure 2 As shown, the difference between Embodiment 2 and Embodiment 1 is that the signal collector also includes a converter current sampler 20, and the output terminal of the controllable step-up DC / DC converter 21 is connected to the load through the converter current sampler 20, The output terminal of the converter current sampler 20 is connected to the ADC terminal of the controller, the converter current sampler 20 is used to detect the output current of the controllable step-up DC / DC converter 21, and the ADC converts the output current of the converter current sampler 20 The signal is converted into a digital signal.

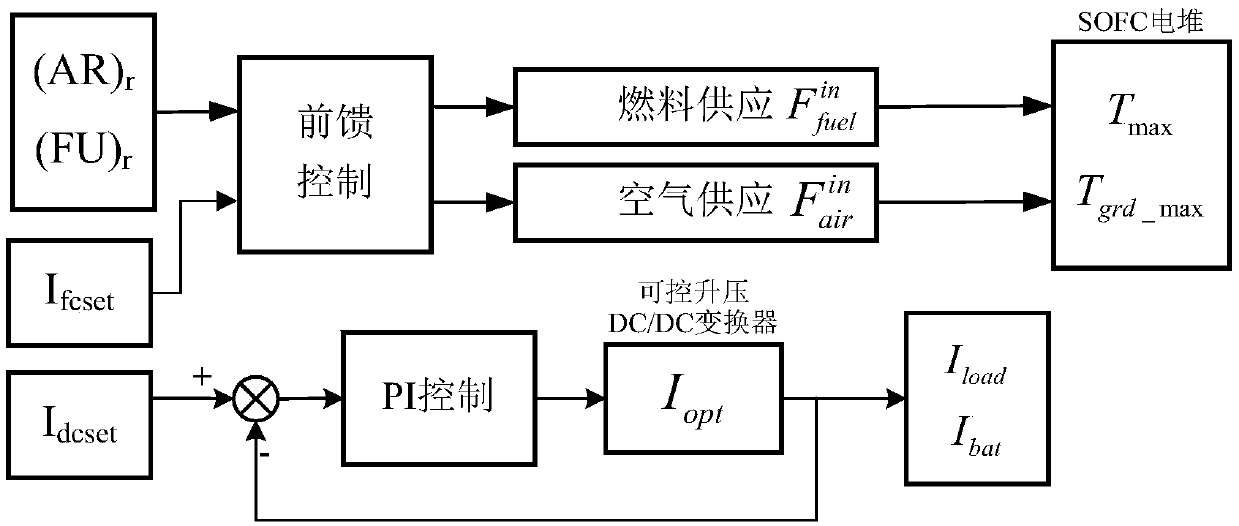

[0066] The concrete control diagram that generates the control signal of bidirectional DC / DC converter 15 in the controller is as image 3 As shown, by setting the air excess ratio AR, the fuel utilization rate FU and the set value I of the stack output current fcset , in order to control the gas temperature T inside the SOFC stack ma...

Embodiment 3

[0075] Such as Figure 4 As shown, the difference between embodiment 3 and embodiment 1 is: the signal collector also includes a combustion chamber temperature sampler 23 and a stack temperature sampler 24, the output end of the combustion chamber temperature sampler 23 and the stack temperature sampler 24 The output ends are all connected with the ADC end of the controller, and the ADC converts the output signal of the combustion chamber temperature sampler 23 and the output signal of the stack temperature sampler 24 into digital signals.

[0076] The specific control diagram for generating the correction value of the fuel flow control signal and the air flow control signal of the SOFC stack system in the controller is as follows: Figure 5 As shown, the sliding mode PID control is performed by detecting the difference between the combustion chamber temperature and the combustion chamber temperature setting value, and the correction of the fuel flow control signal and the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com