BiOCl nanoring and synthetic method thereof

A synthesis method and nanoring technology, applied in the fields of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of difficulty in the synthesis of nanorings, no reports of BiOCl ring nanosheets, etc., and achieve high scientific research value and morphology. Regular, simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

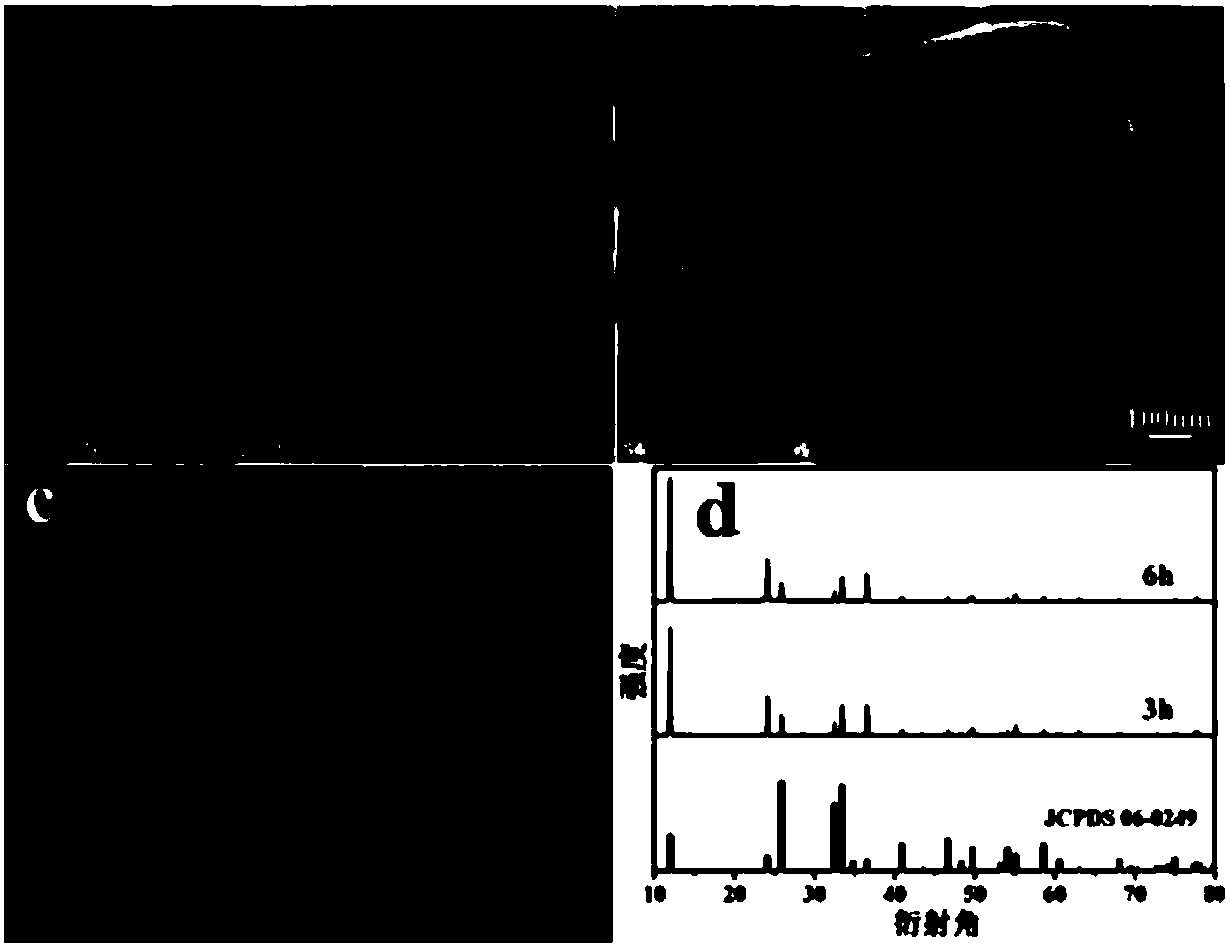

[0024] The invention provides a kind of synthetic method of BiOCl nano ring, described synthetic method comprises the following steps: (1) will contain Bi 3+ , Cl - Carry out heating reaction with the aqueous solution of polyethylene glycol, obtain BiOCl nano sheet; (2) BiOCl nano sheet is etched in acid solution; Wherein, provide Cl - The substance is an alkali metal chloride salt; wherein, the acid solution is a nitric acid solution, a sulfuric acid solution or a mixed solution of nitric acid and sulfuric acid.

[0025] Through the above technical scheme, the present invention can obtain BiOCl nanosheets with center defects in step (1), and through step (2), the defects in the center of BiOCl nanosheets continue to expand and penetrate to obtain BiOCl nanorings. The BiOCl nano ring obtained by the invention not only fills the gap in the synthesis of the BiOCl nano ring, but also has higher photocatalytic activity than the conventional BiOCl nano sheet without holes in the c...

Embodiment 1

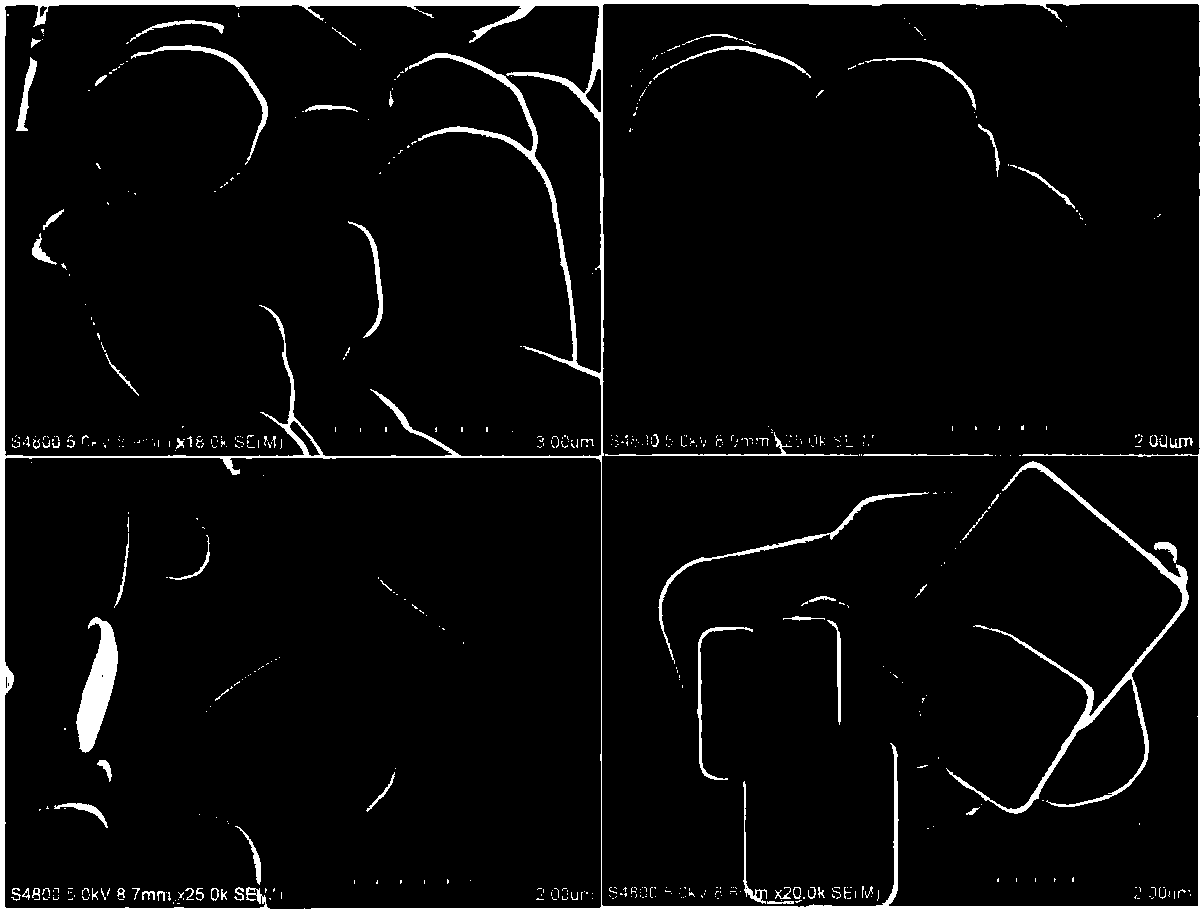

[0047] 1mmol Bi(NO 3 ) 3 ·5H 2 O was sonicated into 15 mL of distilled water, labeled as A solution. 1mmol KCl was added to 15mL distilled water, after ultrasonic dissolution, 0.1g polyethylene glycol (PEG-6000) was added, ultrasonically dispersed, and marked as B solution. Solution B was added dropwise to solution A, and the mixed solution was stirred for 30 minutes. Finally transferred to a 40mL autoclave and heated at 160°C for 12 hours. After the reaction, it was naturally cooled to room temperature, the product was washed with distilled water and ethanol, and dried to constant weight. The product was marked as BiOCl-S.

[0048] Weigh 0.03 g of the above synthesized product and ultrasonically disperse it into 15 mL of 1mol L -1 HNO 3 In the solution, stirring was continued for 6 h to obtain the final product, which was labeled as BiOCl-R.

Embodiment 2

[0050] (1) Dissolve bismuth nitrate, sodium chloride and polyethylene glycol (number average molecular weight is 3350) in water, will contain Bi 3+ , Cl - and an aqueous solution of polyethylene glycol were heated at 140°C for 15 hours to obtain BiOCl nanosheets; Bi in aqueous solution 3+ The concentration is 20mmol / L, Bi in aqueous solution 3+ and Cl - The ratio of the amount of substance is 1:0.8; relative to 1mmol of Bi 3+ , the mass content of polyethylene glycol is 0.05g;

[0051] The product after the heating reaction in step (1) is cooled, washed with distilled water and ethanol several times and dried;

[0052] (2) The BiOCl nanosheets were ultrasonically dispersed in a 0.8 mol / L nitric acid solution, stirred continuously, and etched for 3 hours; the amount of nitric acid solution used was 100 mL relative to 1 g of BiOCl nanosheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com