Formation method of ternary soft-package battery cell

A chemical synthesis method and cell technology, applied in electrochemical generators, circuits, electrical components, etc., can solve problems such as reducing the cycle performance of lithium-ion batteries, and achieve the effects of high density, improved cycle performance, and improved cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

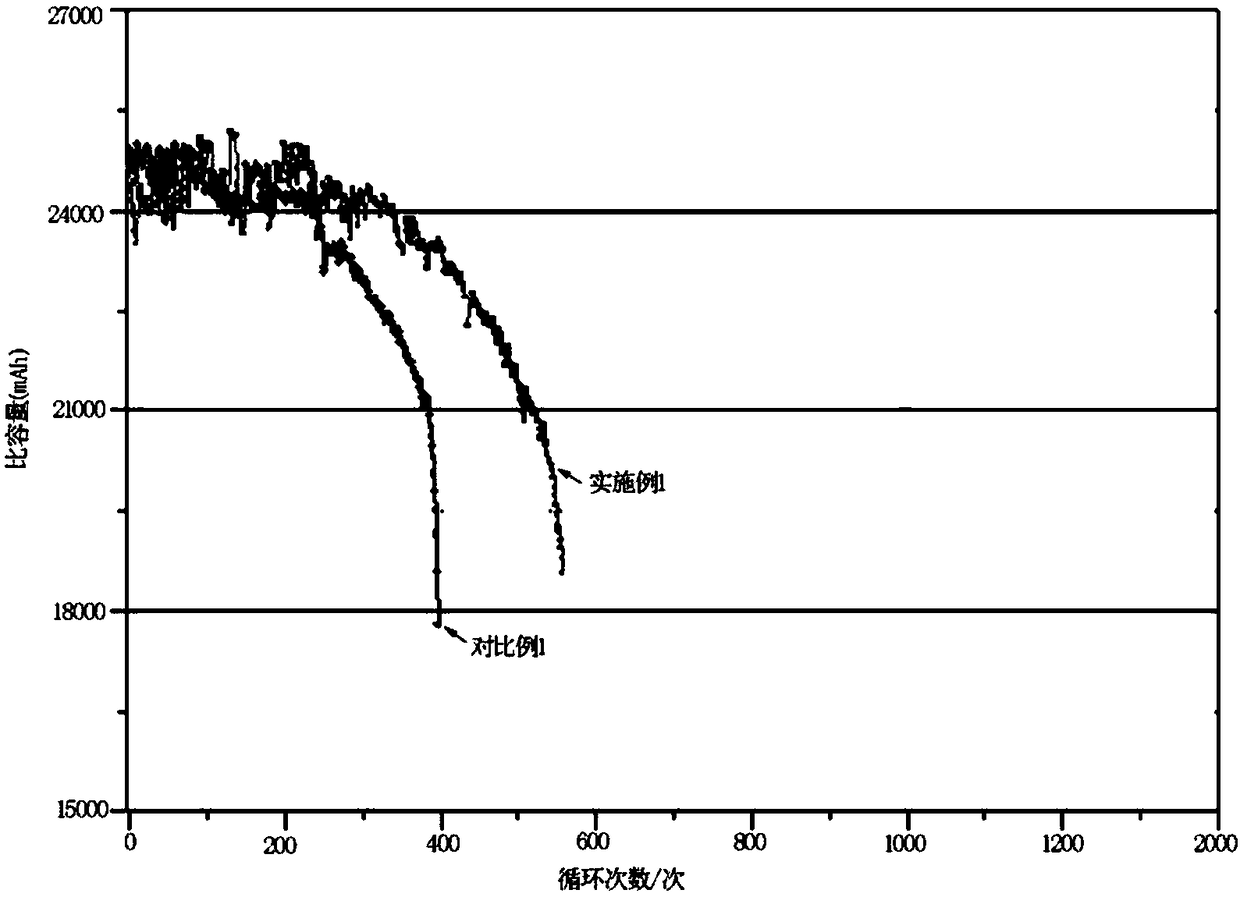

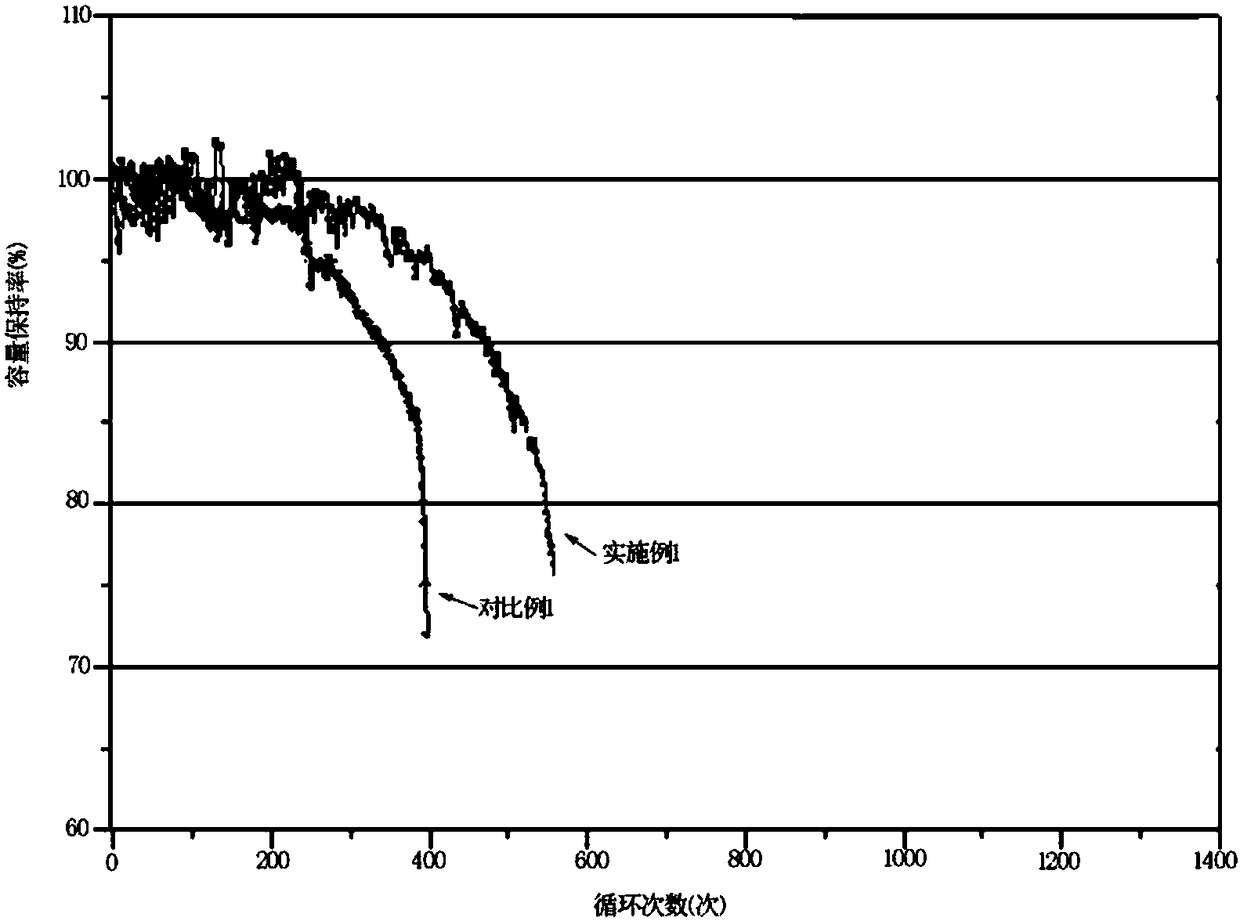

Embodiment 1

[0048] A method for forming a ternary soft-pack battery cell, wherein the battery cell involved is positive electrode nickel cobalt lithium manganese oxide 523, the negative electrode active material is artificial graphite, the diaphragm is ceramic diaphragm, and the electrolyte is 1.0mol / L LiPF 6 / EC+EMC+DEC (volume ratio EC:EMC:DEC=1:1:1) system, the electrolyte contains 1.5% biphenyl overcharge additive, the diaphragm is a PP-based ceramic diaphragm, and the cell structure is a laminated A total of 100 batteries are formed in this embodiment, which specifically includes the following steps:

[0049] 1). Put the pre-sealed battery cell without abnormality in the formation cabinet, and connect the circuit;

[0050] 2). Carry out chemical formation according to the following chemical formation process:

[0051] (1) The temperature is 55±3°C, the surface pressure of the cell is 380kPa, the charging current is 0.05C, and the charging time is 0.5h;

[0052] (2) The temperature ...

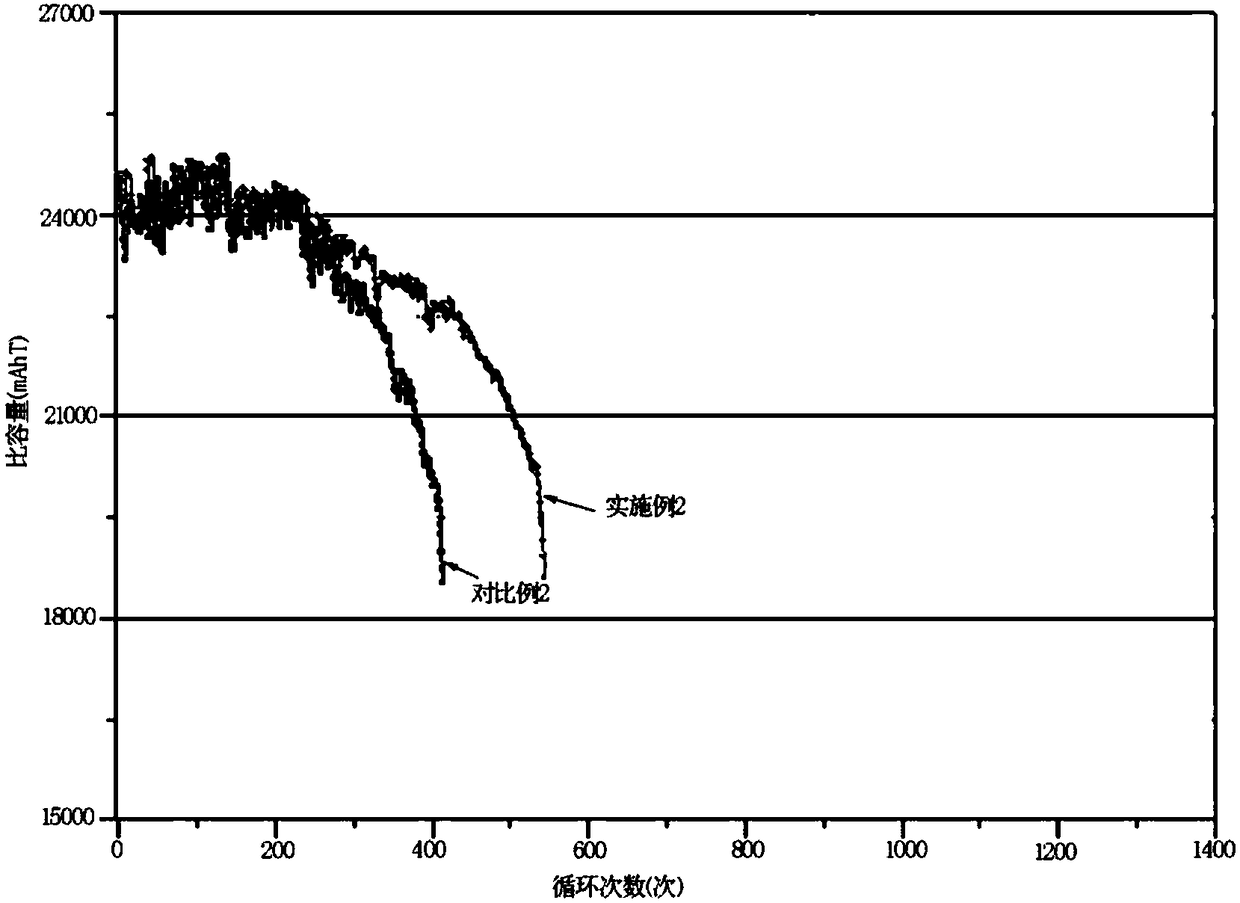

Embodiment 2

[0058] A method for forming a ternary soft-pack battery cell, wherein the battery cell involved is positive electrode nickel cobalt lithium manganese oxide 523, the negative electrode active material is artificial graphite, the diaphragm is ceramic diaphragm, and the electrolyte is 1.0mol / L LiPF 6 / EC+EMC+DEC (volume ratio EC:EMC:DEC=1:1:1) system, the electrolyte contains 1.5% biphenyl overcharge additive, the diaphragm is a PP-based ceramic diaphragm, and the cell structure is a laminated A total of 100 batteries are formed in this embodiment, which specifically includes the following steps:

[0059] 1). Put the pre-sealed battery cell without abnormality in the formation cabinet, and connect the circuit;

[0060] 2). Carry out chemical formation according to the following chemical formation process:

[0061] (1) The temperature is 55±3°C, the surface pressure of the cell is 220kPa, the charging current is 0.05C, and the charging time is 1.0h;

[0062] (2) The temperature ...

Embodiment 3

[0068] A method for forming a ternary soft-pack battery cell, wherein the battery cell involved is positive electrode nickel cobalt lithium manganese oxide 523, the negative electrode active material is artificial graphite, the diaphragm is ceramic diaphragm, and the electrolyte is 1.0mol / L LiPF 6 / EC+EMC+DEC (volume ratio is EC:EMC:DEC=1:1:1) system, the electrolyte does not contain overcharge additives, the diaphragm is a PP-based ceramic diaphragm, and the cell structure is a laminated soft pack battery Cells, this embodiment is converted into a total of 100 batteries, which specifically includes the following steps:

[0069] 1). Put the pre-sealed battery cell without abnormality in the formation cabinet, and connect the circuit;

[0070] 2). Carry out chemical formation according to the following chemical formation process:

[0071] (1) The temperature is 55±3°C, the surface pressure of the cell is 220kPa, the charging current is 0.05C, and the charging time is 0.5h;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com