Method for separating and preparing petunidin 3-galactoside chloride

A technology for petunin and galactoside, which is applied in the field of separation and preparation of petunin-3-O-galactoside, and can solve the problem of separation and preparation of petunin-3-O-galactoside that has not been found. Issues such as body research and reporting, to achieve the effect of large sample processing volume and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

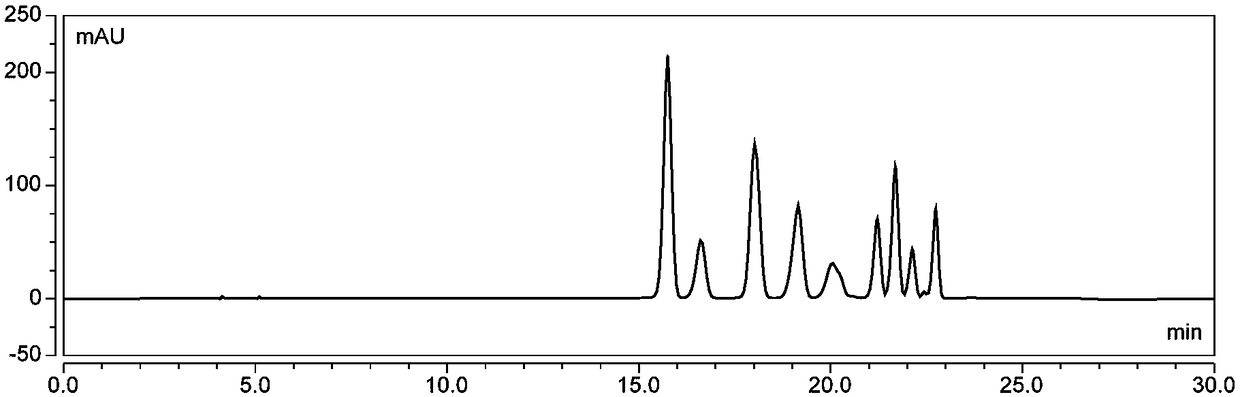

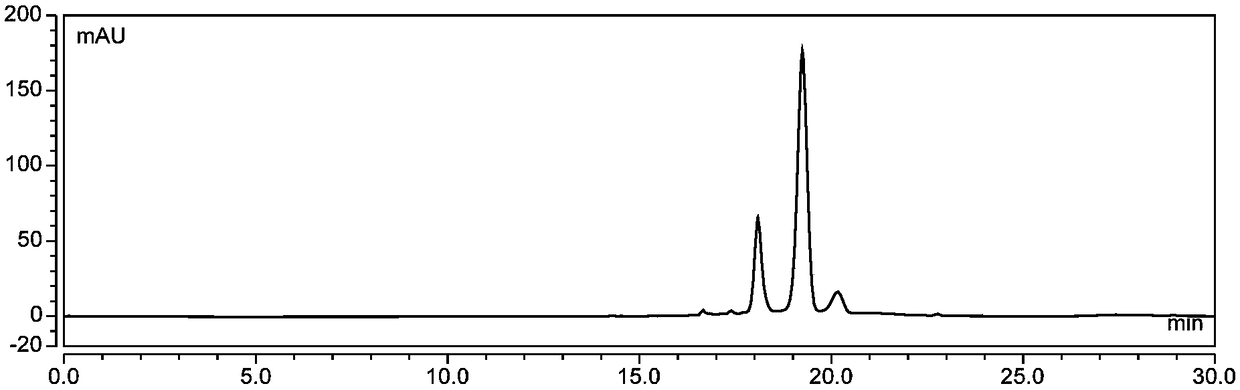

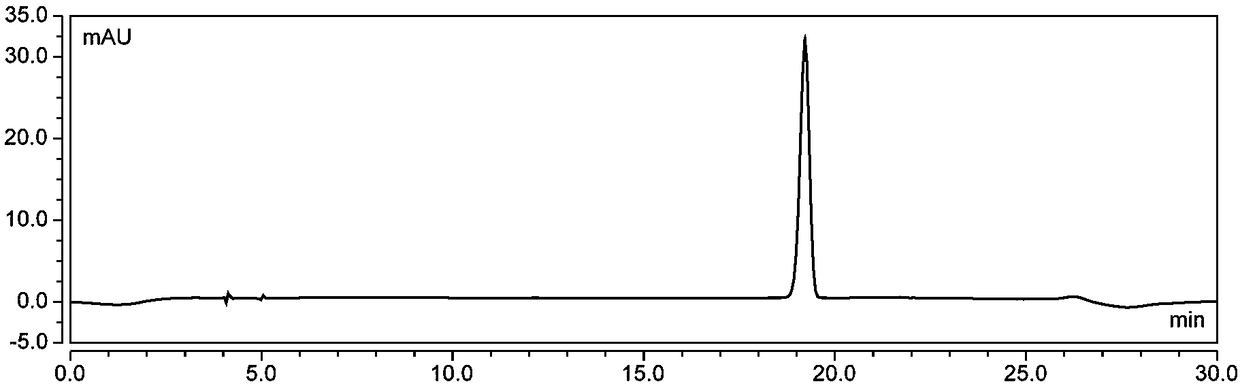

Image

Examples

Embodiment 1

[0069] (1) Wash 1000g of fresh blueberries, add 70% ethanol aqueous solution containing 0.1% (v / v) hydrochloric acid (volume of ethanol and water) according to the ratio of solid to liquid 1:7 (w / v, g / mL) Ratio of 70:30) was fully mixed, ultrasonically extracted for 90 minutes, (45°C, protected from light), vacuum filtered, the filter residue was extracted twice according to the above conditions, the filtrate was combined, and ethanol was removed by vacuum rotary evaporation at 48°C to obtain crude anthocyanins extract;

[0070] (2) The AB-8 macroporous resin soaked in ethanol for 24h is packed into a chromatographic column, washed with deionized water until there is no alcohol smell, washed with 4% hydrochloric acid solution for 1h at a flow rate of 2BV / h, and then deionized Wash with ionized water until the effluent is neutral; wash with 4% sodium hydroxide solution at a flow rate of 2BV / h for 1 hour, and then wash with deionized water until neutral. Inject the crude anthoc...

Embodiment 2

[0076] (1) Wash 3kg of fresh blueberries, add 80% ethanol aqueous solution containing 1.0% (v / v) hydrochloric acid according to the ratio of solid to liquid 1:9 (w / v) and mix thoroughly, ultrasonically extract for 120min, (45°C hereinafter, protected from light), filtered under reduced pressure, and the filter residue was repeatedly extracted 3 times according to the above conditions, and the filtrate was combined, and the ethanol was removed by vacuum rotary evaporation at 46°C to obtain a crude anthocyanin extract;

[0077] (2) The AB-8 macroporous resin soaked in ethanol for 24h is packed into a chromatographic column, washed with deionized water until there is no alcohol smell, washed with 4% hydrochloric acid solution for 1h at a flow rate of 2BV / h, and then deionized Wash with ionized water until the effluent is neutral; wash with 4% sodium hydroxide solution at a flow rate of 2BV / h for 1 hour, and then wash with deionized water until neutral. Inject the crude anthocyani...

Embodiment 3

[0082] (1) Wash 5kg of fresh blueberries, add 90% ethanol aqueous solution containing 1.5% (v / v) hydrochloric acid according to the ratio of material to liquid (w / v) of 1:8 (w / v), mix thoroughly, and extract by ultrasonic for 200min, (45°C hereinafter, protected from light), filtered under reduced pressure, and the filter residue was repeatedly extracted 4 times according to the above conditions, the filtrates were combined, and the ethanol was removed by vacuum rotary evaporation at 47°C to obtain a crude anthocyanin extract;

[0083] (2) The AB-8 macroporous resin soaked in ethanol for 24h is packed into a chromatographic column, washed with deionized water until there is no alcohol smell, washed with 4% hydrochloric acid solution for 1h at a flow rate of 2BV / h, and then deionized Wash with ionized water until the effluent is neutral; wash with 4% sodium hydroxide solution at a flow rate of 2BV / h for 1 hour, and then wash with deionized water until neutral. Inject the crude an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com