A method for controlling the ultra-fine crystallization gradient of a deep tapered copper medicine mask

A control method and a technology for a drug-type cover, which are applied to explosive charges, offensive equipment, weapon accessories, etc., can solve the problems of large anisotropy of rolled sheets, complicated processes, and low yield of nanocrystalline materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

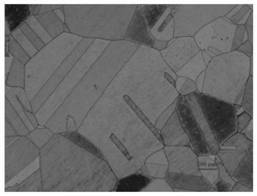

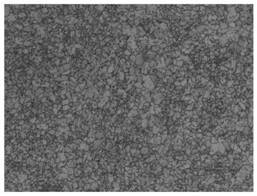

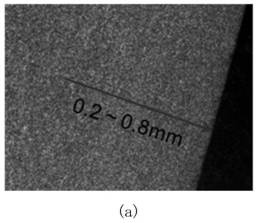

[0039] (1) Preparation of the blank: Taking the variable-wall thickness medicine cover with a double cone structure as an example, the medicine cover has a diameter of 165mm, height 178mm, inner cone depth 142mm, and wall thickness 2.4~3.2mm. The small cone angle at the top is 36°, the large cone angle is 64°, the transition arc between the large cone angle and the small cone angle is R220mm; according to the theory of plastic processing and the principle of nearly uniform plastic deformation, 0.3mm is left on the outer surface of the medicine cover The process allowance of φ25mm is designed on the top of the medicine type cover; the forming process is simulated, analyzed and optimized by UG and DEFORM software, and the volume of the blank is calculated. The extruded T2 copper rod of φ90mm is selected as Raw material, cut and turn the outer surface to make a blank with a diameter of 88mm and a height of 55mm; the impurity element content of the T2 red copper bar is shown in Tabl...

Embodiment 2

[0055] (1) Preparation of the blank: Take the medicine-type cover of equal wall thickness with a single cone structure as an example. The diameter of the medicine-type cover is φ156mm, height 162mm, inner cone depth 148mm, maximum wall thickness 3.2mm, and inner cone angle 60 °According to the theory of plastic working and forming and the principle of nearly uniform plastic deformation, a machining allowance of 0.4mm is left on the outer surface of the multi-pass extrusion molding cover forming part, and a φ20mm forming process boss is designed on the top of the molding cover forming part ;Using UG and DEFORM software to simulate the forming process, and calculate the volume of the blank, choose φ60mm drawn T2 copper rod as the raw material, cut and turn the outer surface to make a blank with a diameter of 58mm and a height of 80mm. The blanks are kept at 400±1℃ for 2 hours in the VQG-2500 intelligent temperature-controlled vacuum heat treatment furnace, and the vacuum degree is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com