Tin collecting plate and manufacturing method thereof

A manufacturing method and technology of tin sheet, which is applied in the direction of manufacturing tools, auxiliary devices, coatings, etc., can solve the problems of low service life of coatings, improve the ability to resist high-temperature oxidation pollution, and have low requirements for substrate surface roughness and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

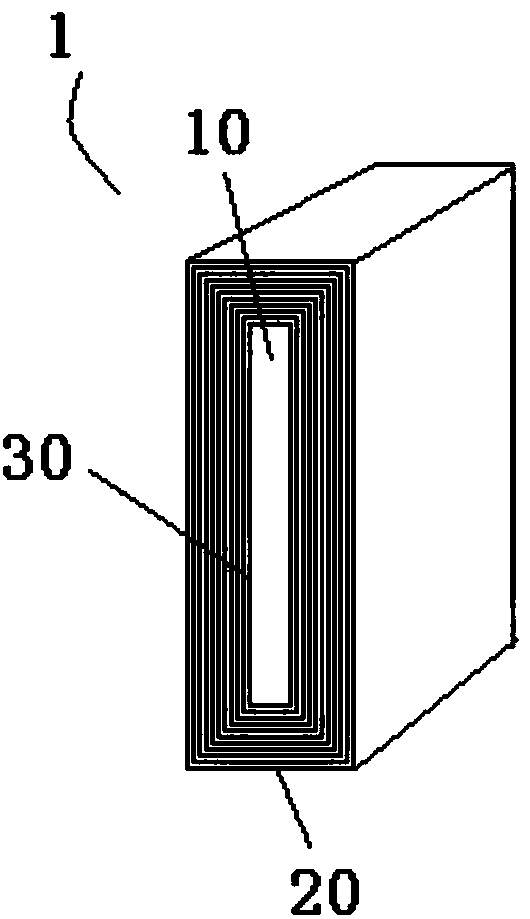

[0045] Such as figure 1 As shown, a tin receiving sheet 1 is provided in this embodiment, and the tin receiving sheet 1 includes a substrate 10, a plurality of activation layers 30, and a plurality of immersion coating layers 20, wherein the outer surface of the substrate 10 is sequentially The activation layer 30 and the immersion coating layer 20 are formed alternately, the outermost layer is the immersion coating layer 20, that is, the substrate 10 is in the innermost layer, the activation layer 30 and the immersion coating layer 20 are stacked alternately, the activation layer 30 is close to the substrate, and the final The outer layer is an immersion plating layer 20 .

[0046]Specifically, in the tin receiving sheet 1, the surface of the outermost immersion coating 20 of the tin receiving sheet 1 is a mirror surface, and the mirror surface is to cover the knife marks or unevenness on the surface of the substrate 10, so as to avoid high temperature during use. Oxidation ...

Embodiment 2

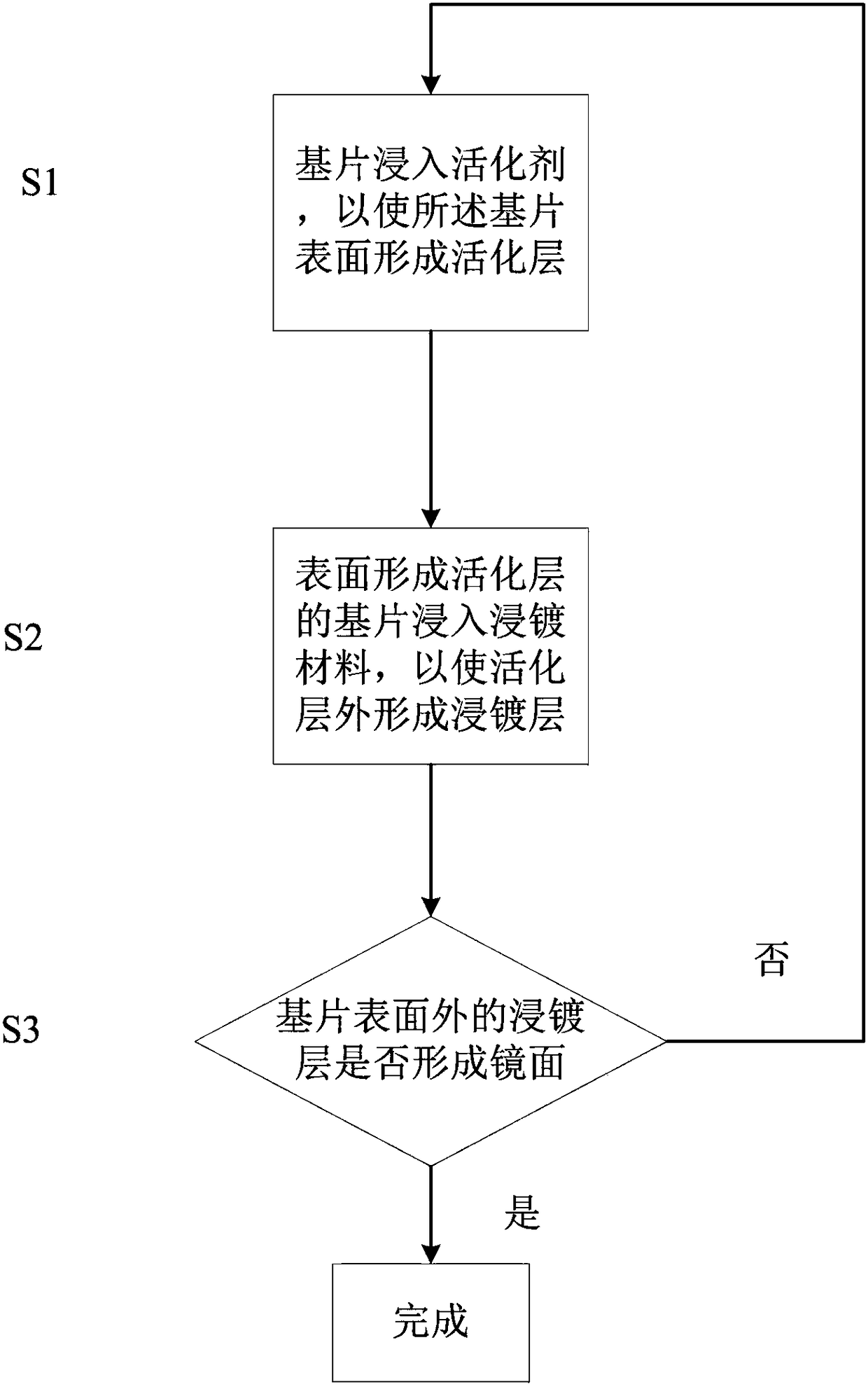

[0050] Such as figure 2 As shown, the present embodiment provides a method for making tin receiving sheet, figure 2 It is a flow chart of the manufacturing method of the tin receiving sheet in this embodiment. The manufacturing method of the tin receiving sheet has the following steps:

[0051] S1: The substrate is immersed in an activator to form an activation layer on the surface of the substrate;

[0052] S2: The substrate with the active layer formed on the surface is immersed in the immersion plating material to form an immersion plating layer outside the active layer;

[0053] S3: Determine whether the immersion coating layer outside the substrate surface forms a mirror surface, if the immersion coating layer outside the substrate surface does not form a mirror surface, then perform steps S1 to S3 again, if the immersion coating layer outside the substrate surface forms a mirror surface, then Finish.

[0054] Specifically, such as figure 2 As shown, steps S1, S2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com