Water body eutrophication control system and method

A technology for water eutrophication and control system, which is applied in water treatment parameter control, chemical instruments and methods, water/sewage treatment, etc. Low operating cost, guaranteed cleanliness, and remarkable activation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

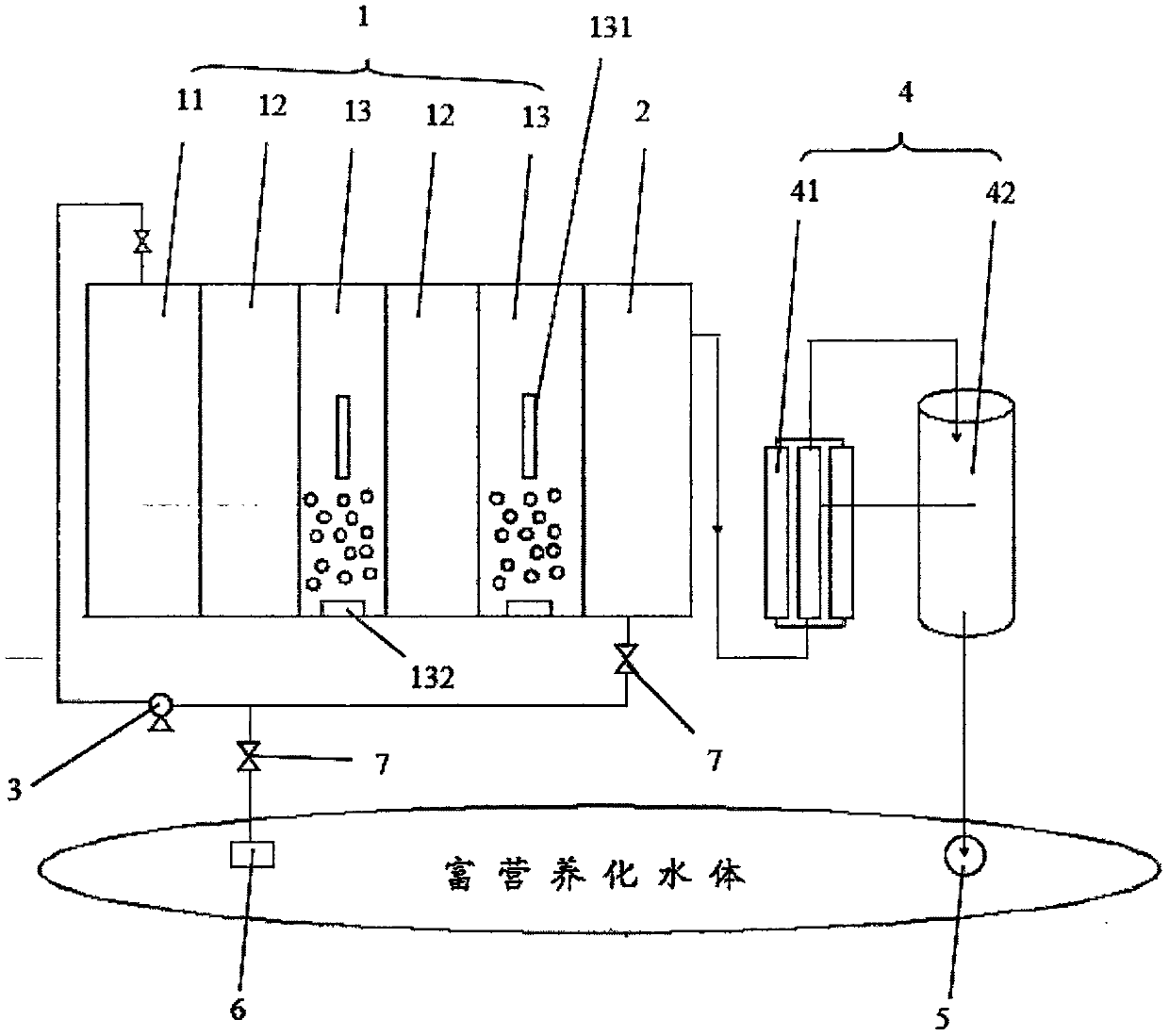

[0038] S1: The eutrophic water body and the treated water with high sludge concentration at the bottom of the sedimentation tank 2 are pumped into the anaerobic zone 11 through the self-priming pump 3, and then pass through the anoxic zone 12, the aerobic zone 13, the anoxic zone 12, and the aerobic zone Zone 13, sedimentation tank 2, wherein the dissolved oxygen in the anoxic zone is controlled at 0.1mg / L, and the dissolved oxygen in the aerobic zone is controlled at 0.5mg / L;

[0039] S2: The water in the sedimentation tank 2 flows to the microfiltration membrane filter 41 through the outlet, and after removing suspended matter, it enters the hydroxyl iron filter bed 42, and the treated regenerated water flows into the water body through the water distributor 5, where the hydroxyl iron filter The particle size of the bed is less than 3nm, and the water flow rate is 12 bed volumes / hour.

[0040] One month later, the experimental water quality was tested, and the removal rate o...

Embodiment 2

[0042] S1: The eutrophic water body and the treated water with high sludge concentration at the bottom of the sedimentation tank 2 are pumped into the anaerobic zone 11 through the self-priming pump 3, and then pass through the anoxic zone 12, the aerobic zone 13, the anoxic zone 12, and the aerobic zone Zone 13, sedimentation tank 2, wherein the dissolved oxygen in the anoxic zone is controlled at 0.01mg / L, and the dissolved oxygen in the aerobic zone is controlled at 0.7mg / L;

[0043]S2: The water in the sedimentation tank 2 flows to the microfiltration membrane filter 41 through the outlet, and after removing suspended matter, it enters the hydroxyl iron filter bed 42, and the treated regenerated water flows into the water body through the water distributor 5, where the hydroxyl iron filter The particle size of the bed is less than 3nm, and the flow through water is 11 bed volumes / hour.

[0044] One month later, the experimental water quality was tested, and the removal rat...

Embodiment 3

[0046] S1: The eutrophic water body and the treated water with high sludge concentration at the bottom of the sedimentation tank 2 are pumped into the anaerobic zone 11 through the self-priming pump 3, and then pass through the anoxic zone 12, the aerobic zone 13, the anoxic zone 12, and the aerobic zone Zone 13, sedimentation tank 2, wherein the dissolved oxygen in the anoxic zone is controlled at 0.2mg / L, and the dissolved oxygen in the aerobic zone is controlled at 0.8mg / L;

[0047] S2: The water in the sedimentation tank 2 flows to the microfiltration membrane filter 41 through the outlet, and after removing suspended matter, it enters the hydroxyl iron filter bed 42, and the treated regenerated water flows into the water body through the water distributor 5, where the hydroxyl iron filter The particle size of the bed is less than 3nm, and the water flow rate is 10 bed volumes / hour.

[0048] One month later, the experimental water quality was tested, and the removal rate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com