Device and technology used for processing dry method calcium carbide residue and realizing acetylene gas recovery

A technology of carbide slag and acetylene gas, which is applied in the purification/separation of hydrocarbons, chemical instruments and methods, hydrocarbons, etc., can solve the problems of VOCs increase, waste of acetylene resources, environmental pollution, etc. With the precipitation process, it is convenient for storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Fill the carbide slag from the dry acetylene generator into a glass tube with a radius of 2 cm and a height of 8 cm, and lightly tap the wall of the glass tube to make the carbide slag powder in the tube dense. The filling amount of the carbide slag powder is 75g. The lower part of the glass tube is provided with a material receiving plate and a gas distribution plate, and the CO at 100°C 2 The gas is passed into the tube at a flow rate of 0.5L / min to contact and react with carbide slag, and the gas flow and composition changes at the upper end of the glass tube are simultaneously detected. After ventilating for 2 hours, the reaction was ended, and the glass tube was disassembled to detect the solid content in the glass tube. It was found that part of the carbide slag was converted into calcium carbonate. The main components of the gas at the upper end of the glass tube were water vapor and carbon dioxide. The collected crude acetylene gas was about 0.07g .

Embodiment 2

[0039] Select the dry process carbide slag of the same batch as Example 1, fill it in a glass tube with a radius of 2 cm and a height of 8 cm, and gently tap the wall of the glass tube to make the carbide slag powder in the tube dense, and the carbide slag powder The loading amount of the material is still 75g. CO at 100°C 2 The gas is introduced into the calcium carbide slag layer through the gas distribution plate at a flow rate of 0.75 L / min to contact and react with it, and the reaction is completed after aeration for 1 hour. The collected crude acetylene gas is measured to be about 0.055 g.

Embodiment 3

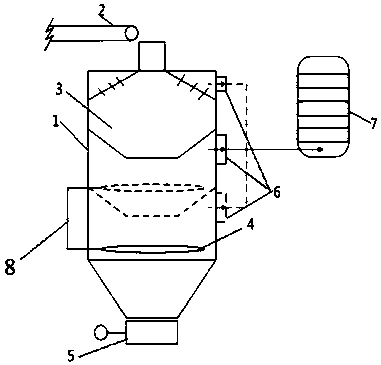

[0041] according to figure 1 The shown device makes a fixed bed reactor 1, which has a diameter of 0.3m and a height of 0.5m, and the amount of dry carbide slag filled inside is 30 kg. The bottom of the fixed bed reactor 1 is provided with a gas distributor 4, which will be heated to 120 °CCO 2 The gas is introduced into the carbide slag pile from the gas distributor 4 of the fixed bed reactor 1, and the gas flow is controlled at 0.1Nm 3 / min, the amount of crude acetylene gas collected from the upper part of the reactor after 60 minutes of reaction is about 50g.

[0042] The preferred gas distributor 4 of the present invention adopts a variable-aperture gas distribution plate, and the apertures of the gas distribution holes on the gas distribution plate gradually become larger along the gas flow path to realize CO 2 Uniform distribution of gas.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com