A method and system for producing natural vitamin E

A natural vitamin and a certain amount of technology, applied in the direction of organic chemistry, can solve the problems of vitamin E activity reduction and instability, and achieve the effect of mild reaction, high efficiency and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

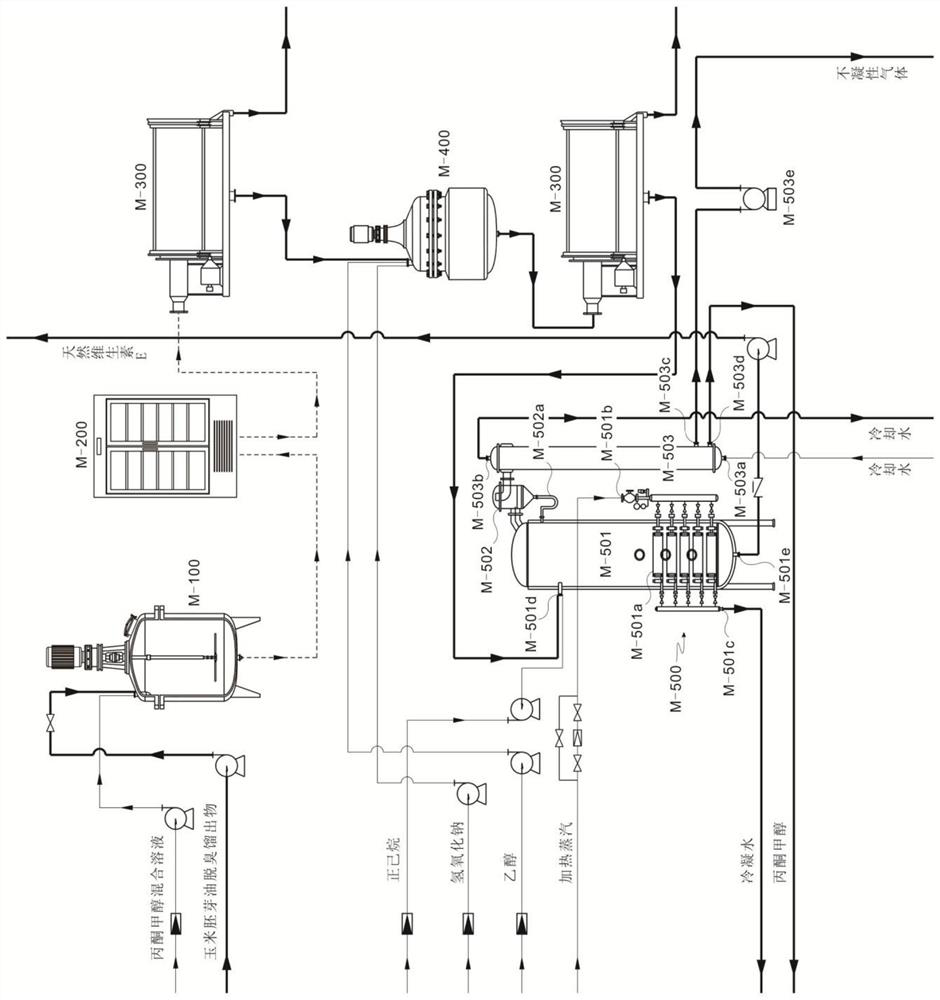

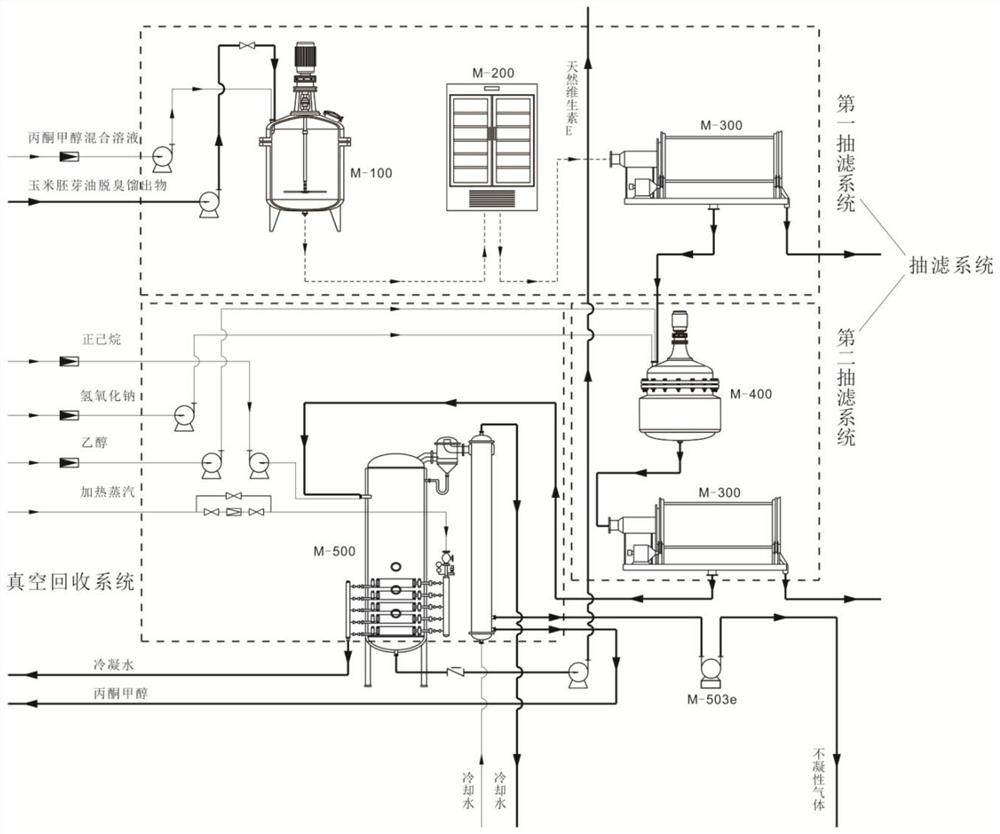

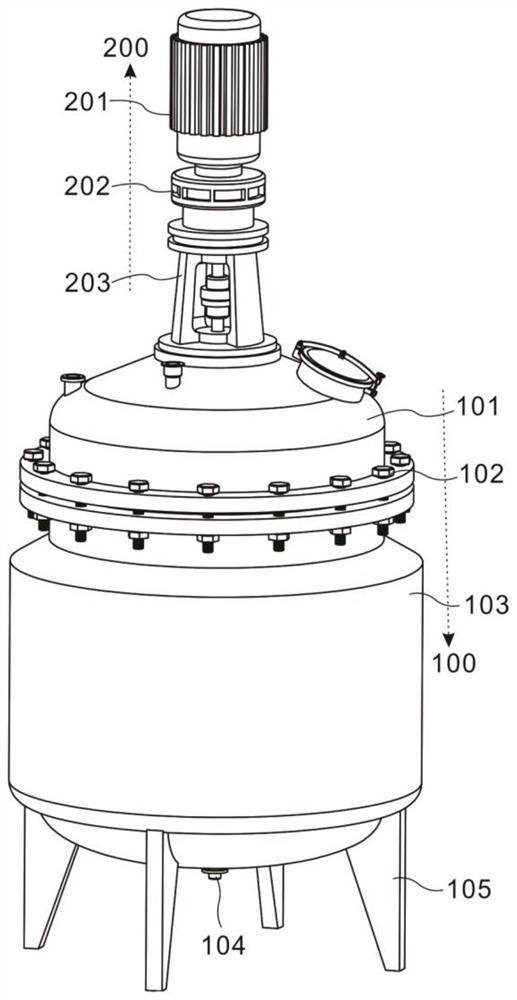

[0052] This embodiment provides a system for producing natural vitamin E, and a method for producing natural vitamin E by the process system. The system for producing natural vitamin E includes a suction filtration system and a vacuum recovery system, wherein the suction filtration system includes a first suction filtration system and a second suction filtration system, such as figure 2 shown.

[0053] The first suction filtration system includes a stirring unit and a first suction filtration unit, and a refrigeration unit is also arranged between the stirring unit and the first suction filtration unit. The stirring unit in the present invention adopts the stirring tank M-100, the freezing unit adopts the medicine refrigerator M-200, and the first suction filter unit adopts the vacuum suction filter M-300. In addition, the second suction filtration system includes a reaction unit and a second suction filtration unit. The reaction unit in the present invention adopts reactor...

Embodiment 2

[0067] Select the deodorized distillate of corn germ oil, put it into the mixing tank M-100, and add the acetone-methanol mixed solution (the injection amount is monitored by the flowmeter) into it through the injection pump, the acetone and methanol in the acetone-methanol mixed solution The volume ratio is 1:4, add 4 liters of acetone methanol mixed solution per kilogram of corn germ oil deodorization distillate, then control the jacket temperature of the stirring tank at 40°C, and stir the reaction at 400rpm for 20min. After the reaction is finished, take out the mixture, transfer it to the medicine refrigerator M-200, adjust the internal temperature of the medicine refrigerator M-200 to -8°C, and make it crystallize at -8°C for 8 hours. Then take out the mixture again and place it in the vacuum filter M-300 for vacuum filtration, obtain the first filtrate, and inject it into the reactor M-400.

[0068] Utilize two injection pumps to add the ethanol of the first filtrate qu...

Embodiment 3

[0071] Select the deodorized distillate of corn germ oil, put it into the mixing tank M-100, and add the acetone-methanol mixed solution (the injection amount is monitored by the flowmeter) into it through the injection pump, the acetone and methanol in the acetone-methanol mixed solution The volume ratio is 1:3.5, add 4 liters of acetone methanol mixed solution per kilogram of corn germ oil deodorized distillate, then control the jacket temperature of the stirring tank at 45 ° C, and stir the reaction at 300 rpm for 20 min. After the reaction is finished, take out the mixture, transfer it to the medicine refrigerator M-200, adjust the internal temperature of the medicine refrigerator M-200 to -5°C, and make it crystallize at -5°C for 8 hours. Then take out the mixture again and place it in the vacuum suction filter M-300 for vacuum suction filtration, obtain the first filtrate, and inject it into the reactor M-400;

[0072] At the same time, use two injection pumps to add ethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com