A guide beam device for hot-rolled section steel

A beam and section steel technology, applied in the field of beams, can solve the problems of shortening the preparation time, lack of effective preparation methods for guide beams, etc., and achieve the effects of simple and easy preparation methods, easy materials, and optimized performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

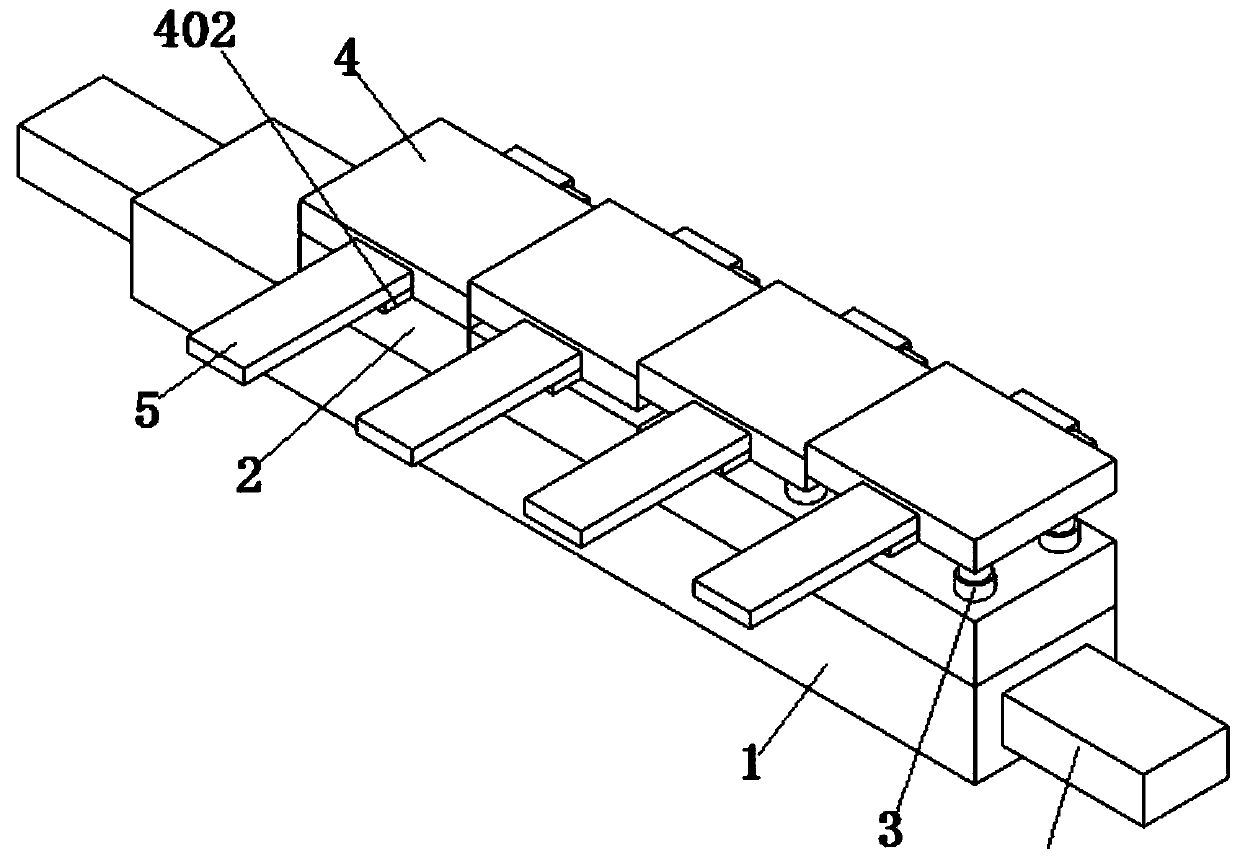

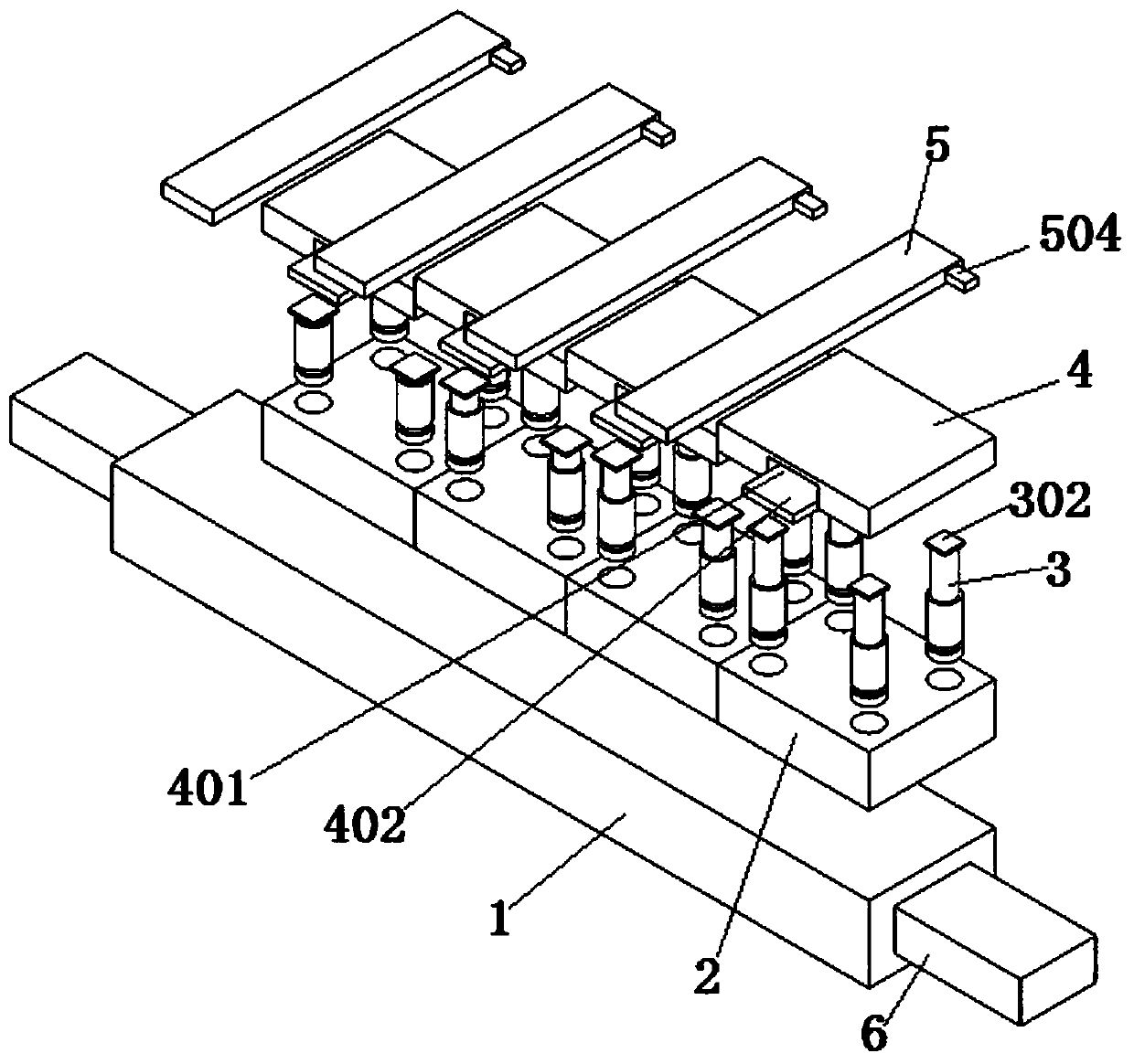

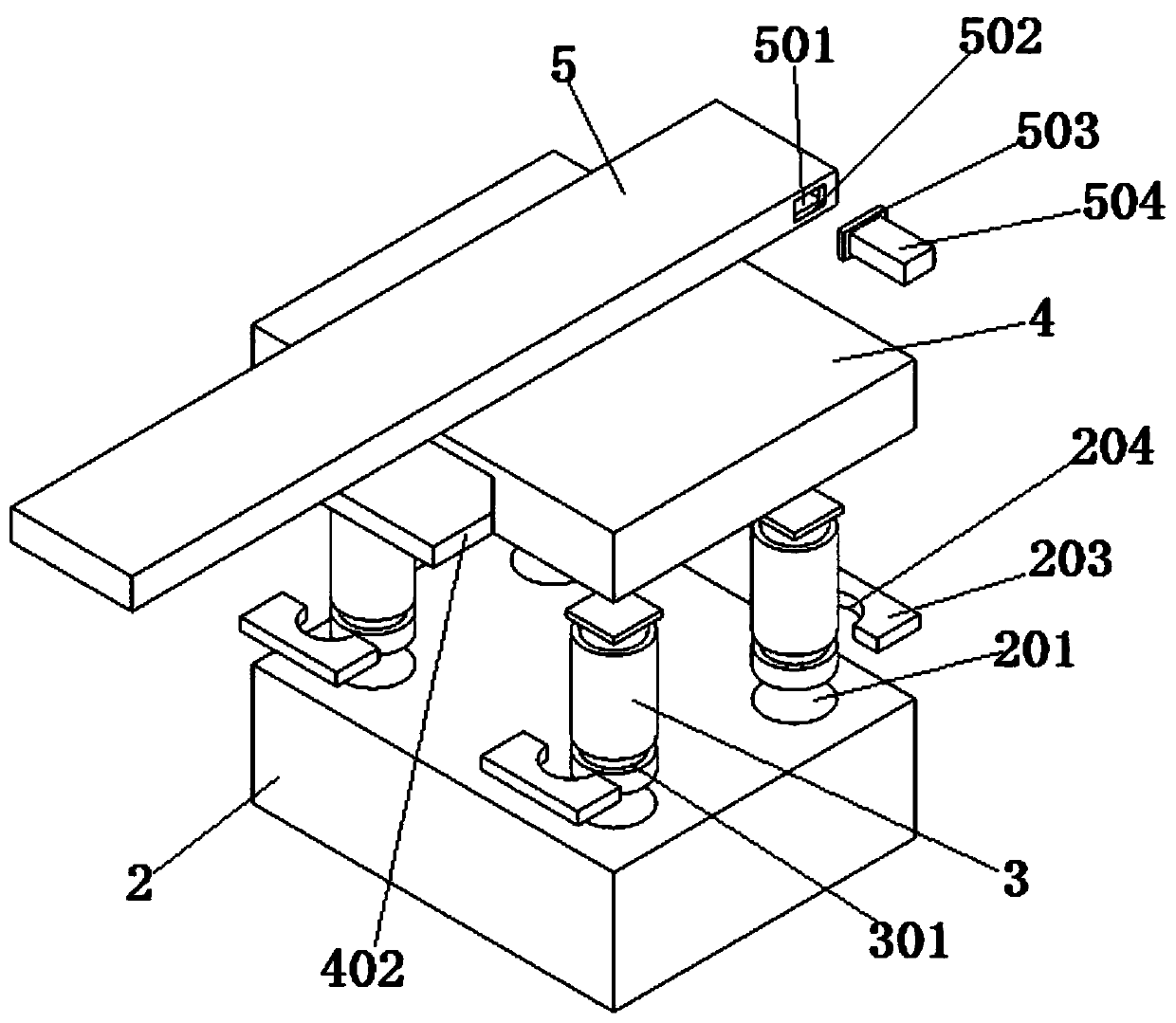

[0031] As embodiment one of the present invention: as Figure 1-6 As shown, a guide crossbeam device for hot-rolled section steel includes a rolling mill frame, a guide beam is installed on the rolling mill stand, a crossbeam device is installed on the guide beam, and the crossbeam device includes a guide A crossbeam 1, the upper end of the guide crossbeam 1 is also fixedly connected with a number of parallel support bases 2, the upper end of the support base 2 is also provided with a number of telescopic rods 3, and the upper end of the telescopic rod 3 is also connected to the first base 4. The first base 4 is also provided with a first fixing through hole 401, the first fixing through hole 401 is provided with a first pedal 5, and the first pedal 5 and the first fixing through hole 401 are connected to each other. Cooperate; the lower end of the first fixing through hole 401 is also provided with an auxiliary fixing support plate 402, and the auxiliary fixing support plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com