Preparation method, product and application of pH-responsive ultra-small iron oxide nanoparticle assembly

An iron oxide nanometer, responsive technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Example 1: Synthesis of ultra-small iron oxide nanoparticles coated with oleic acid

[0058] (1) Dissolve 10 g of ferric chloride hexahydrate and 36 g of sodium oleate in a mixed solution of 80 mL of ethanol, 60 mL of water and 140 mL of hexane, and stir at 70° C. for 4 hours. After the reaction, the oil phase part is extracted with water and dried to obtain the oil-iron composite.

[0059] (2) Take 1.8g of oil-iron complex and dissolve it in 0.6g of oleic acid, 1.6g of oleyl alcohol and 10g of diphenyl ether mixed solution, raise the temperature to 250°C under the protection of argon, and keep stirring at this temperature for 30 minutes. After the reaction is cooled, add Acetone precipitates and centrifuges to obtain ultra-small iron oxide nanoparticles in the oil phase, and the size of the nanoparticles is 3-4 nm.

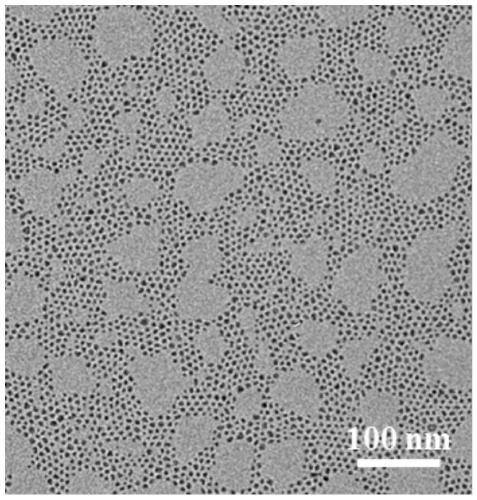

[0060] The morphology of the prepared oleic acid-coated ultra-small iron oxide nanoparticles was characterized by transmission electron microscopy, as sh...

Embodiment 2

[0061] Example 2: Synthesis of carboxyl-modified ultra-small iron oxide nanoparticles

[0062] 100 mg of oleic acid-modified ultra-small iron oxide nanoparticles were dissolved in 7.5 ml of o-dichlorobenzene, and 100 mg of citric acid and 7.5 ml of N,N-dimethylformamide were added. Stir at 100°C for 24 hours under the protection of argon. After the reaction, add ether and acetone for precipitation, and centrifuge to obtain carboxyl-modified ultra-small iron oxide nanoparticles.

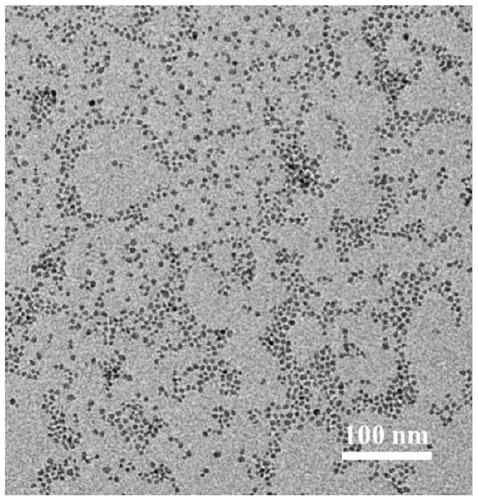

[0063] The morphology of the prepared carboxyl-modified ultra-small iron oxide nanoparticles was characterized by transmission electron microscopy, as shown in figure 2 shown.

Embodiment 3

[0064] Example 3: Synthesis of Carboxyl-Modified Ultra-Small Iron Oxide Nanoparticles

[0065] The synthesis was carried out with reference to the preparation process of Example 2, the difference being that the added oleic acid modified ultra-small iron oxide nanoparticles was changed to 20 mg, and carboxyl-modified ultra-small iron oxide nanoparticles were also obtained.

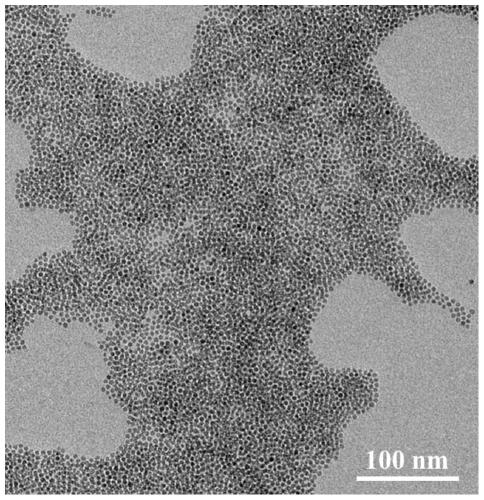

[0066] The morphology of the carboxyl-modified ultra-small iron oxide nanoparticles prepared by changing the method was characterized by transmission electron microscopy, as shown in image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com