Epoxy resin/cement mortar compound concrete material and preparation method therefor

A technology of epoxy resin and cement mortar, applied in the field of road material preparation, can solve the problems of poor comprehensive performance of semi-flexible pavement, poor thermal construction period, poor durability, etc., achieve excellent mechanical properties and process properties, and reasonable crushed stone gradation , the effect of the appropriate ratio of glue to stone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Epoxy resin / cement mortar composite concrete material is composed of high porosity epoxy resin crushed stone mixture and high fluidity polymer modified cement mortar. Porosity The internal pores of the epoxy resin crushed stone mixture form a dense composite structure after the two are consolidated and formed.

[0038] The high-porosity epoxy resin crushed stone mixture is composed of a single-component epoxy resin adhesive and crushed stones, the porosity is 20%, and the mass ratio of crushed stones to the adhesive is 100:6. Crushed stone is a mixture of basalt rock with a particle size of 3-5mm and basalt rock with a particle size of 5-10mm, and the mass ratio of the two is 2:1.

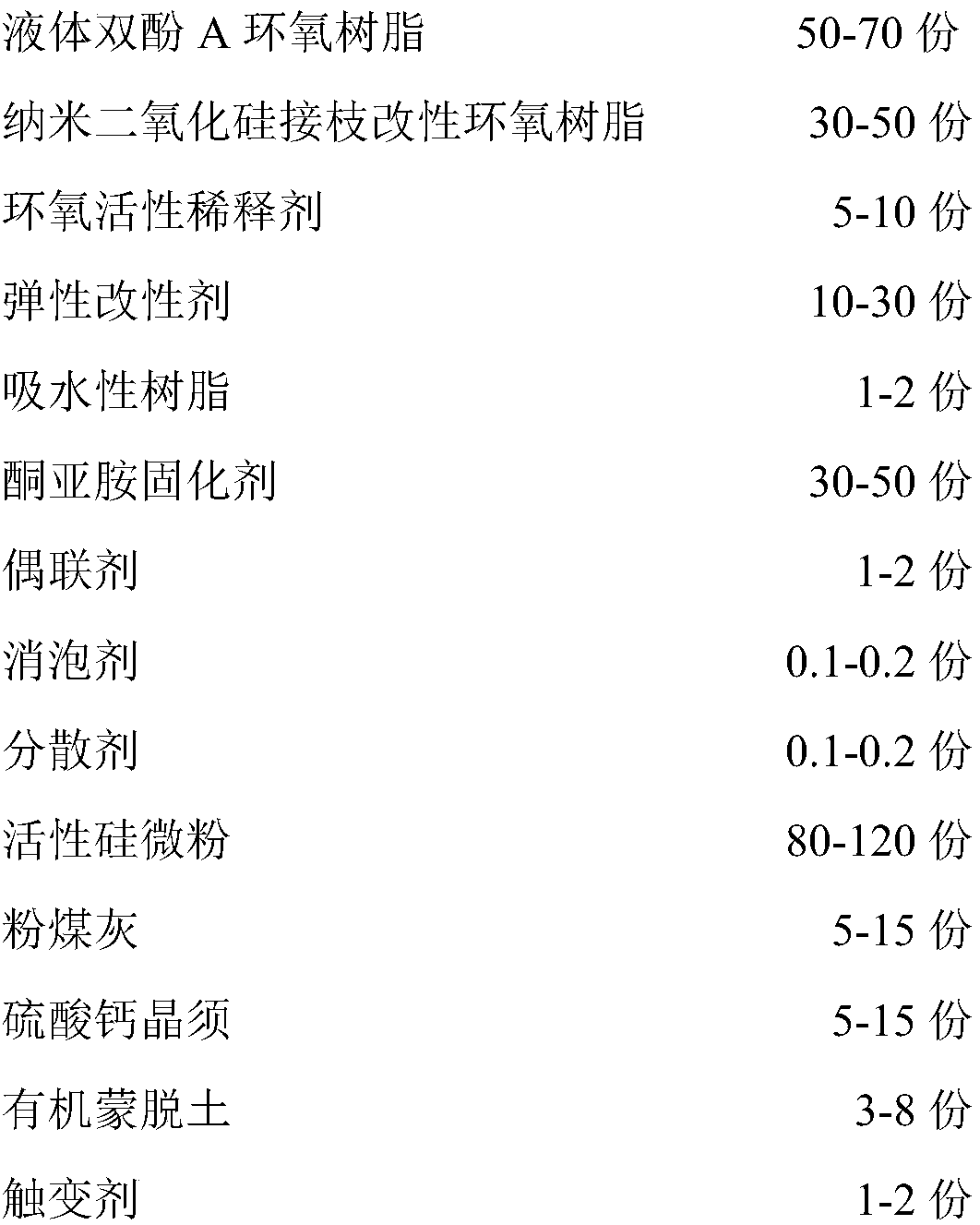

[0039] The one-component epoxy resin adhesive is a water-activated one-component epoxy resin adhesive, and the formula composition in parts by mass is as follows:

[0040]

[0041] The preparation method of described one-component epoxy resin adhesive, its concrete steps are:

[0042] 1...

Embodiment 2

[0055] Epoxy resin / cement mortar composite concrete material is composed of high porosity epoxy resin crushed stone mixture and high fluidity polymer modified cement mortar. Porosity The internal pores of the epoxy resin crushed stone mixture form a dense composite structure after the two are consolidated and formed.

[0056] The high-porosity epoxy resin crushed stone mixture is composed of a single-component epoxy resin adhesive and crushed stones, the porosity is 30%, and the mass ratio of crushed stones to adhesive is 100:3. Crushed stone is a mixture of basalt rock with a particle size of 3-5mm and basalt rock with a particle size of 5-10mm, and the mass ratio of the two is 1:1.

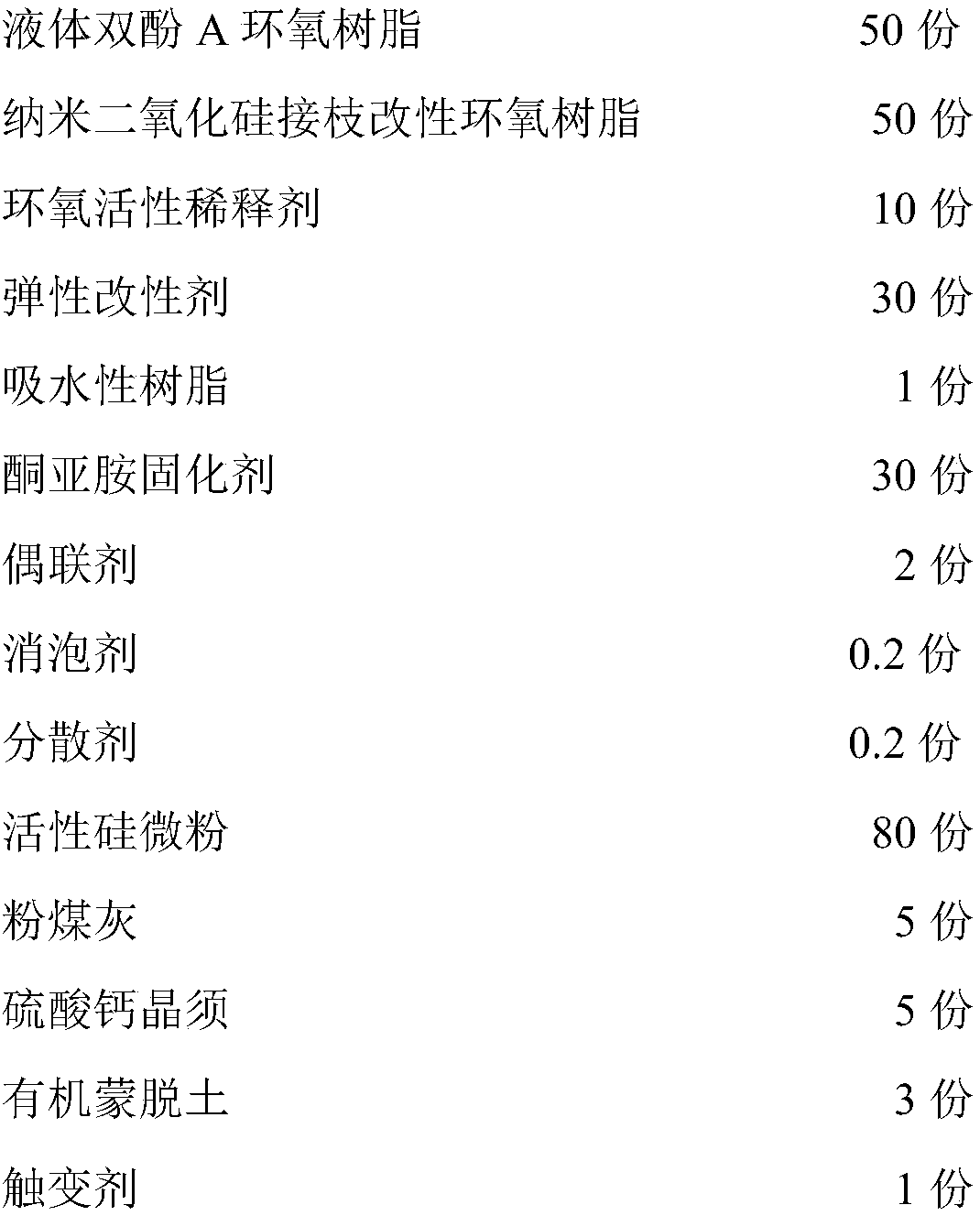

[0057] The one-component epoxy resin adhesive is a water-activated one-component epoxy resin adhesive, and the formula composition in parts by mass is as follows:

[0058]

[0059] The preparation method of described one-component epoxy resin adhesive, its concrete steps are:

[0060] 1) We...

Embodiment 3

[0073] Epoxy resin / cement mortar composite concrete material is composed of high porosity epoxy resin crushed stone mixture and high fluidity polymer modified cement mortar. Porosity The internal pores of the epoxy resin crushed stone mixture form a dense composite structure after the two are consolidated and formed.

[0074] The high-porosity epoxy resin crushed stone mixture is composed of a single-component epoxy resin adhesive and crushed stone, its porosity is 25%, and the mass ratio of crushed stone to adhesive is 100:4.5. Crushed stone is a mixture of basalt rock with a particle size of 3-5mm and basalt rock with a particle size of 5-10mm, and the mass ratio of the two is 1.5:1.

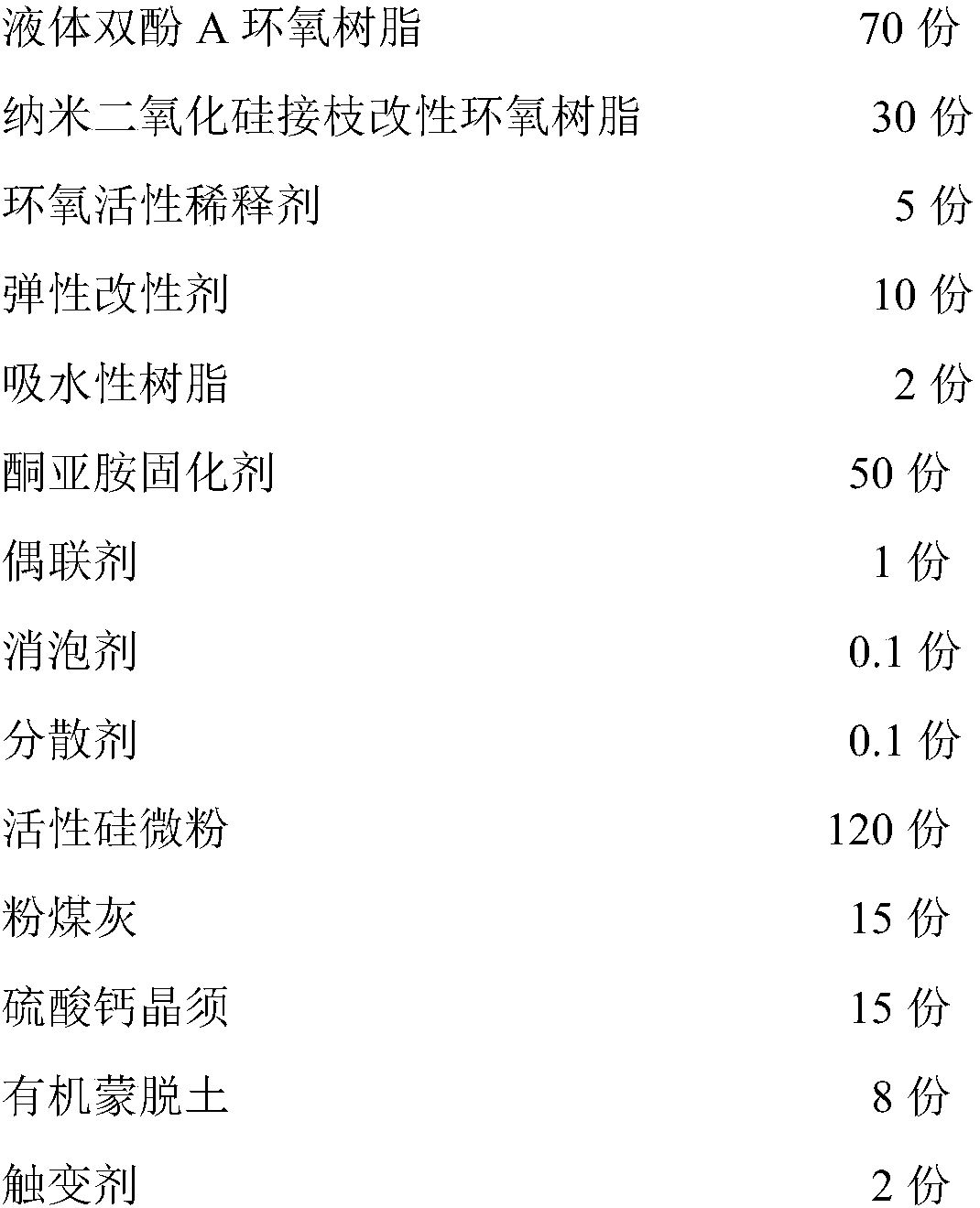

[0075] The one-component epoxy resin adhesive is a water-activated one-component epoxy resin adhesive, and the formula composition in parts by mass is as follows:

[0076]

[0077] The preparation method of described one-component epoxy resin adhesive, its concrete steps are:

[0078] 1) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Consistency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com