II-II-VI alloy quantum dot, as well as preparation method and application thereof

A kind of II-II-VI, II-VI technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] According to the energy level distribution of quantum dots, the core-shell structure formed by CdSe quantum dots and ZnSe quantum dots is a type I structure, that is, the conduction band of CdSe quantum dots is lower than that of ZnSe, while the valence band of CdSe is higher than that of ZnSe. valence band. The valence band and conduction band of the alloy formed by the two should be between the two. To form a fully alloyed quantum dot instead of forming a similar core-shell structure, a relatively complete alloy should be formed from the early stage of nucleation. Although the above-mentioned second method has been able to obtain relatively complete alloyed CdZnSe alloy quantum dots, the size and shape of the quantum dots are not uniform, and the composition of the quantum dots is not uniform. This requires another approach. Based on this, in a typical embodiment of the present application, a method for preparing II-II-VI alloy quantum dots is provided, including: St...

Embodiment 1

[0066] CD x Zn 1-x Synthesis of Se alloy quantum dots: Weigh basic zinc carbonate (0.22g, 0.4mmol), oleic acid (1.4g, 0.5mmol), and 12mL ODE in a 100mL three-necked flask, and exhaust it with inert gas for 10 minutes to increase The temperature was raised to 280° C. to obtain a clear solution (ie, containing the precursor of the second group II element). After cooling the clear solution to 180°C, inject 1 mL of 0.5 mmol / mL Se-ODE suspension into it, and react for 10 minutes to form a system containing II-VI semiconductor nanoclusters. Subsequently, inject 0.5ml 0.2mmol / mL cadmium oleate solution (that is, the precursor containing the first group II elements) into the above system, and react for 10 minutes to obtain x Zn 1- x The first system of Se alloy quantum dots. Inject 1mL of TBP solution into the first system, raise the temperature to 300°C, and continue the reaction for 60min.

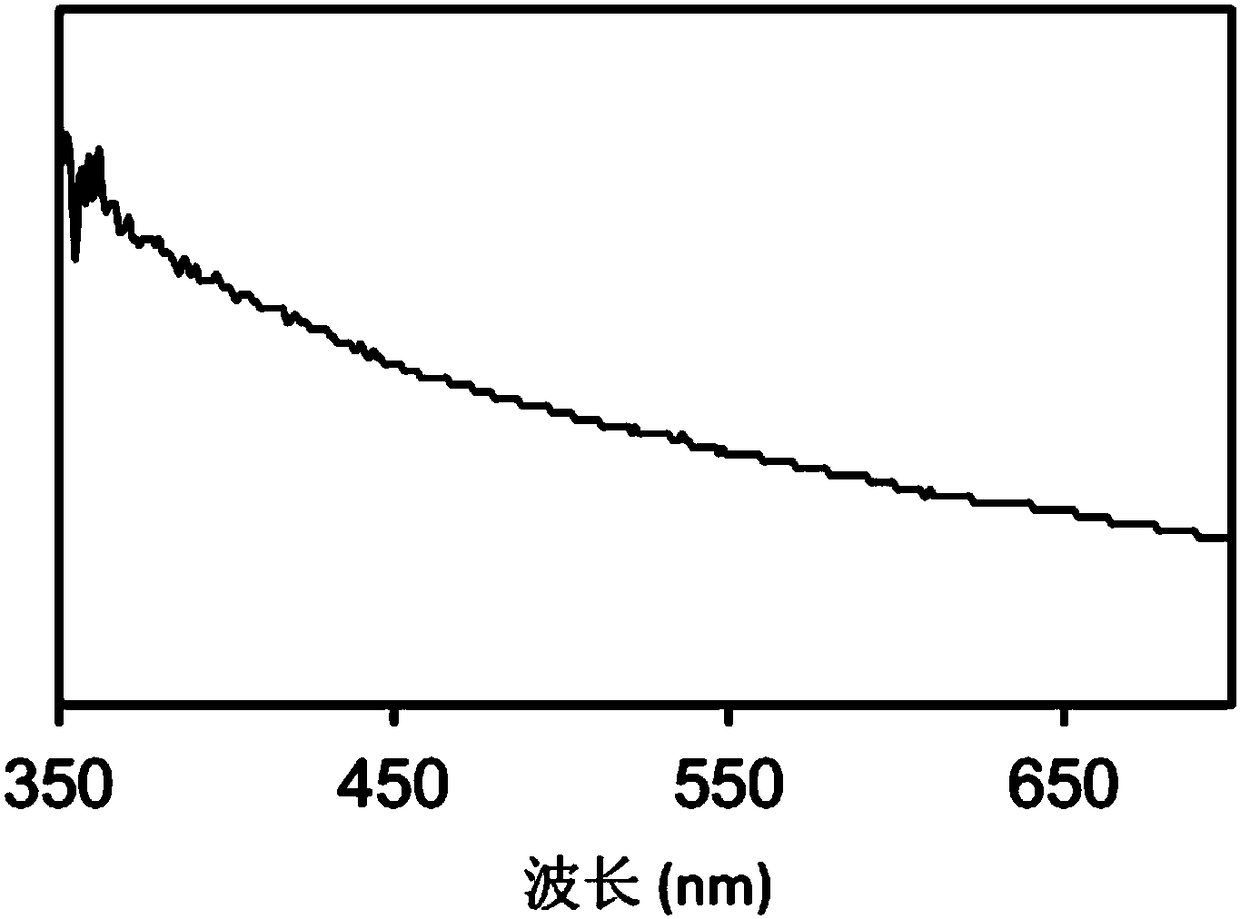

[0067] During the reaction process, a certain amount of reaction solution was injected...

Embodiment 2

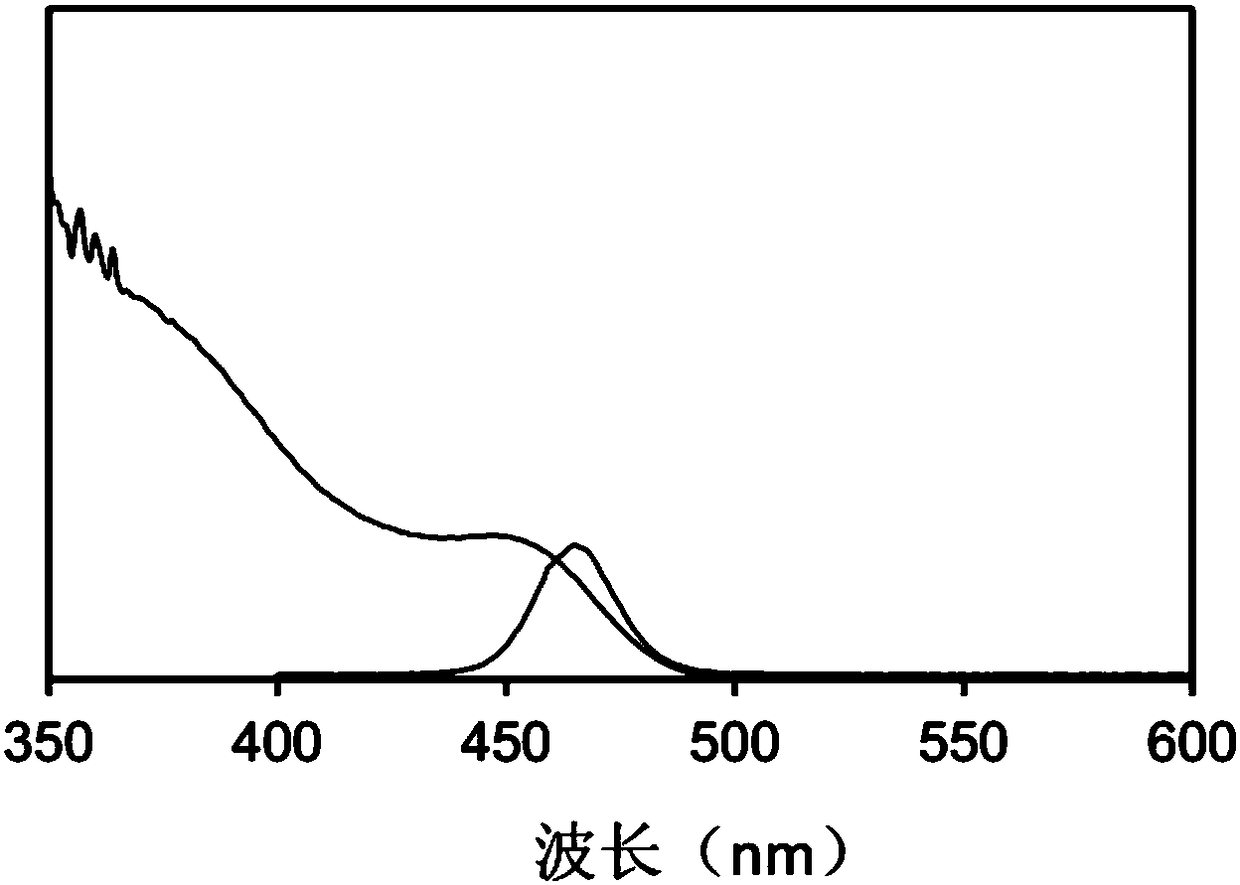

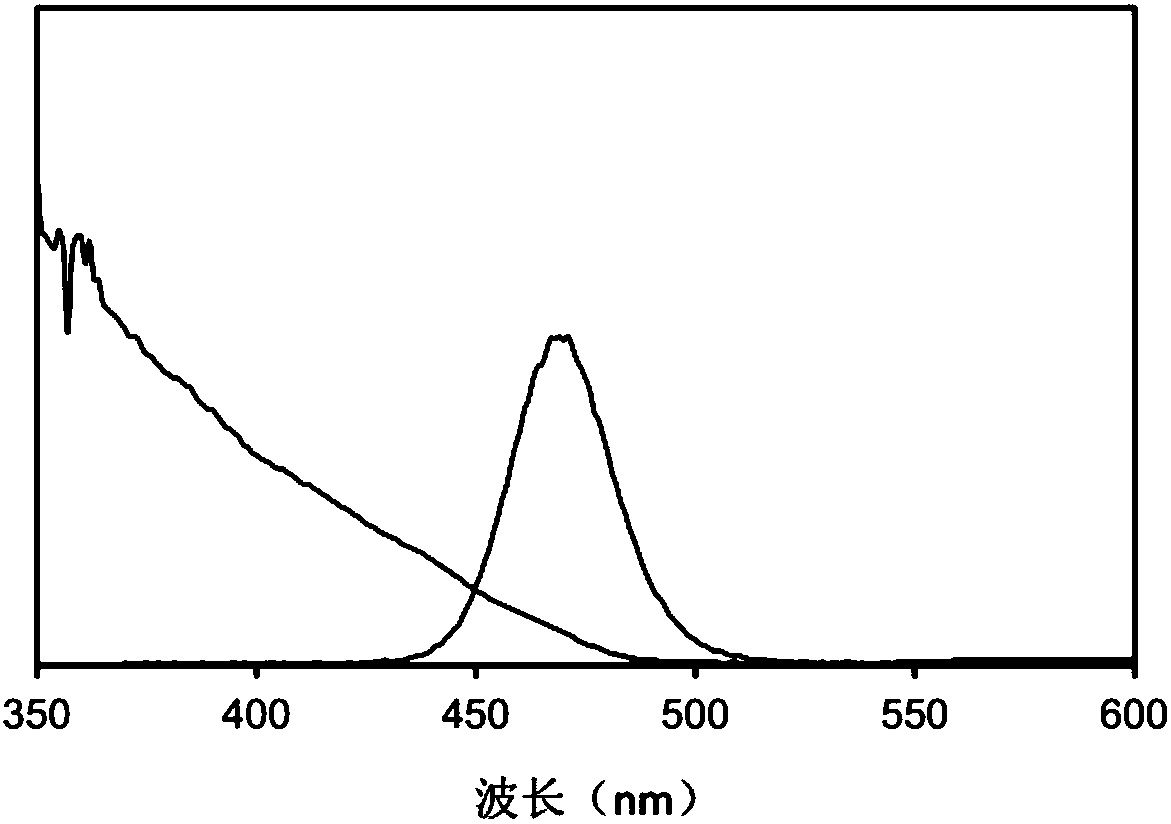

[0069] CD x Zn 1-x Synthesis of Se alloy quantum dots: Weigh basic zinc carbonate (0.22g, 0.4mmol), oleic acid (1.4g, 0.5mmol), and 12mL ODE in a 100mL three-necked flask, and exhaust it with inert gas for 10 minutes to increase The temperature was raised to 280°C to obtain a clear solution. Cool the clear solution to 150°C, inject 1 mL of 0.5 mmol / mL Se-ODE suspension, and react for 10 minutes to form a system containing II-VI semiconductor nanoclusters. Subsequently, 0.5ml of 0.2mmol / mL cadmium oleate solution was injected into the above system, and after 10 minutes of reaction, a Cd-containing x Zn 1-x The first system of Se alloy quantum dots. Inject 1mL of TBP solution into the first system, raise the temperature to 300°C, and continue the reaction for 60min. In the reaction process, a certain amount of reaction solution is injected into a quartz cuvette containing 1-2mL toluene, and the measurement of the ultraviolet-visible absorption spectrum and the fluorescence ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com