Micro light emitting element and manufacturing method thereof

A technology for light-emitting elements and manufacturing methods, which is applied to electrical elements, semiconductor devices, circuits, etc., and can solve the problems of production yield decline, N electrode detachment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

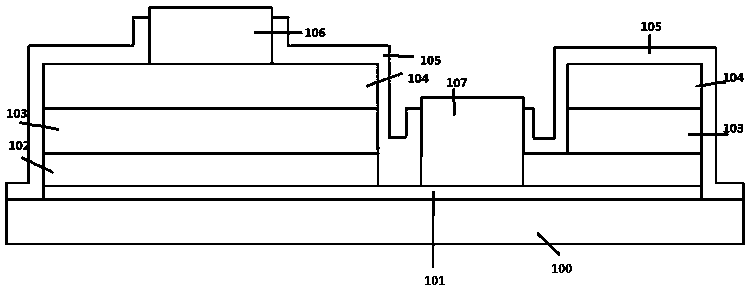

[0032] Concrete preparation method of the present invention is as follows:

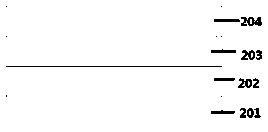

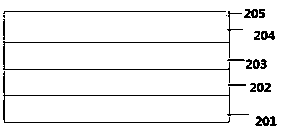

[0033] (1) Provide LED epitaxy structure

[0034] like figure 2 As shown, an epitaxial structure is provided, which may generally include a growth substrate and an epitaxial stack thereon. The growth substrate 201 is selected from gallium arsenide, gallium arsenide, or gallium phosphide, etc., and its surface structure can be a planar structure or a patterned structure. The epitaxial stack includes a growth substrate 201, a GaAs buffer layer 202, (GaInP lattice transition layer is preferably provided), ohmic contact layer, window layer (buffer layer, ohmic contact layer, window layer are not shown in the figure), first semiconductor layer 202, active layer 203, second semiconductor layer 204, current spreading layer (not shown in the figure). The growth substrate 201 is used for epitaxial growth, and a suitable buffer layer material is set according to the growth substrate to eliminate the influen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com