Separator modifying method for zinc in negative battery

A zinc negative electrode and battery technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of high internal impedance of the battery, small pore size, unfriendly environment, etc., and achieve uniform potential distribution, reduce contact angle, and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] Preparation of the positive electrode sheet: first dissolve the binder polyvinylidene fluoride in N-methylpyrrolidone to make a dispersion with a mass fraction of 5%, and add Na 0.44 MnO 4 , acetylene black, and polyvinylidene fluoride are mixed in a mass ratio of 75:20:5, stirred evenly in a high-speed mixer, and the resulting mixture is evenly coated on the surface of graphite conductive paper, moved into a 120°C vacuum oven, and taken out after 6 hours , cut out to get the positive plate.

[0026] Electrolyte preparation: 28.4g of anhydrous sodium sulfate and 28.755g of zinc sulfate heptahydrate plus deionized water were fixed to 100mL, prepared to contain 2mol / L Na 2 SO 4 and 1mol / L ZnSO 4 aqueous solution to obtain an electrolyte.

[0027] Battery assembly: Zinc foil is used as the negative electrode, and the positive electrode sheet is used as the positive electrode, containing 2mol / L Na 2 SO 4 and 1mol / L ZnSO 4 The aqueous solution is used as the electroly...

Embodiment 1

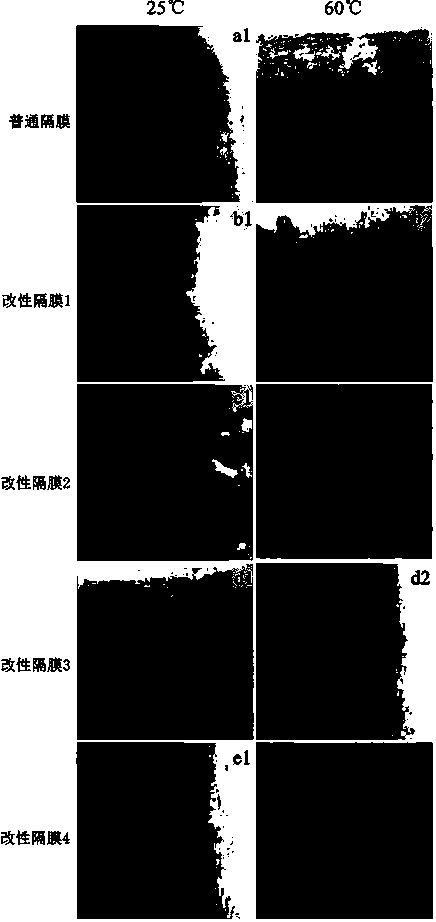

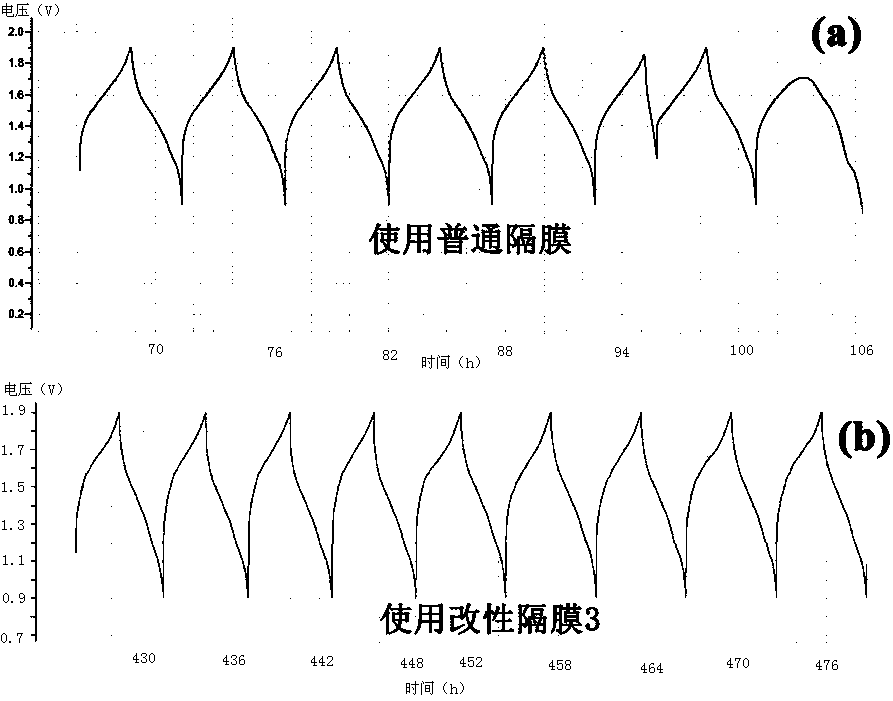

[0034] Such as figure 1 As shown, a diaphragm modification method for zinc negative batteries, first disperses 1.0g of hydroxypropyl methylcellulose in 100g of deionized water to prepare an aqueous dispersion with a mass fraction of about 1%, and then hydroxypropyl methylcellulose The aqueous solution of base cellulose is evenly coated on the cellulose isolation film with a thickness of 0.3mm, put into the oven to dry, and set aside, the coating surface density of hydroxypropyl methylcellulose is 3-5mg / cm 2 , to obtain the self-made modified diaphragm 1.

[0035] Battery assembly: the prepared positive electrode sheet was used as the positive electrode, the zinc foil was used as the negative electrode, and 2mol / L Na 2 SO 4 and 1mol / LZnSO 4 The aqueous solution is used as the electrolyte, the diaphragm is self-made modified diaphragm 1, and the battery is assembled by lamination process. The battery test system for the assembled laminated hard-shell battery is tested. The t...

Embodiment 2

[0038] Such as figure 1 As shown, a method for modifying a separator for a zinc negative electrode battery, first heats and disperses 3.0 g of agar in 100 g of deionized water to prepare an aqueous solution with a mass fraction of about 3%, and evenly coats the agar aqueous solution on a 0.3 mm thick Put it in a cellulose isolation film, dry it in an oven, and set it aside. The density of the coated surface of agar is 3-5mg / cm 2 The self-made modified diaphragm 2 was obtained.

[0039] Battery assembly: the prepared positive electrode sheet was used as the positive electrode, the zinc foil was used as the negative electrode, and 2mol / L Na 2 SO 4 and 1mol / LZnSO 4 The aqueous solution is used as the electrolyte, the diaphragm is self-made modified diaphragm 2, and the battery is assembled by lamination process. The battery test system for the assembled laminated hard-shell battery is tested. The test temperature is 25°C and 60°C, the test current is 35mA / g, and the charge an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com