Co-N-C composite material based on Bio-MOF-11 as well as preparation and application thereof

A technology of bio-mof-11 and composite materials, applied in the direction of catalyst activation/preparation, chemical instruments and methods, electrical components, etc., can solve the problems of high cost, slow reverse reaction activity, etc., and achieve high electrochemical stability, The preparation process is environmentally friendly and the experimental design is ingenious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A Co-N-C composite material based on Bio-MOF-11 is obtained by high-temperature carbonization of Bio-MOF-11, and the Bio-MOF-11 is obtained by reacting cobalt acetate and adenine.

[0030] The preparation method of the Co-N-C composite material based on Bio-MOF-11 comprises:

[0031] 1. Hydrothermal reaction of cobalt acetate and adenine to obtain Bio-MOF-11:

[0032] (1) Mix cobalt acetate and adenine and dissolve in 10 mL of N,N-2 methylformamide, the mass ratio of cobalt acetate and adenine is 1:3;

[0033] (2) Pour the obtained homogeneous mixture into a 50mL polytetrafluoroethylene lining, seal the lining reactor in a stainless steel autoclave, heat it in an oven to 120°C, and then keep it at a constant temperature for 10h;

[0034] (3) After naturally cooling to room temperature, open the lined reactor and pour off the supernatant, add a small amount of distilled water to the remaining white precipitate, centrifuge after stirring, then wash with distilled water a...

Embodiment 2

[0040] Similar to Example 1, the difference from Example 1 is that the carbonization temperature is 600° C., and the finally obtained composite material is denoted as Co-N-C-1.

Embodiment 3

[0042] Similar to Example 1, the difference from Example 1 is that the carbonization temperature is 800° C., and the finally obtained composite material is denoted as Co-N-C-2.

[0043] Use X-ray diffractometer (XRD), scanning electron microscope (SEM), transmission electron microscope (TEM), electrochemical workstation to characterize, the morphology structure and the electrochemical performance of the Co-N-C composite material that the present invention prepares, its The result is as follows:

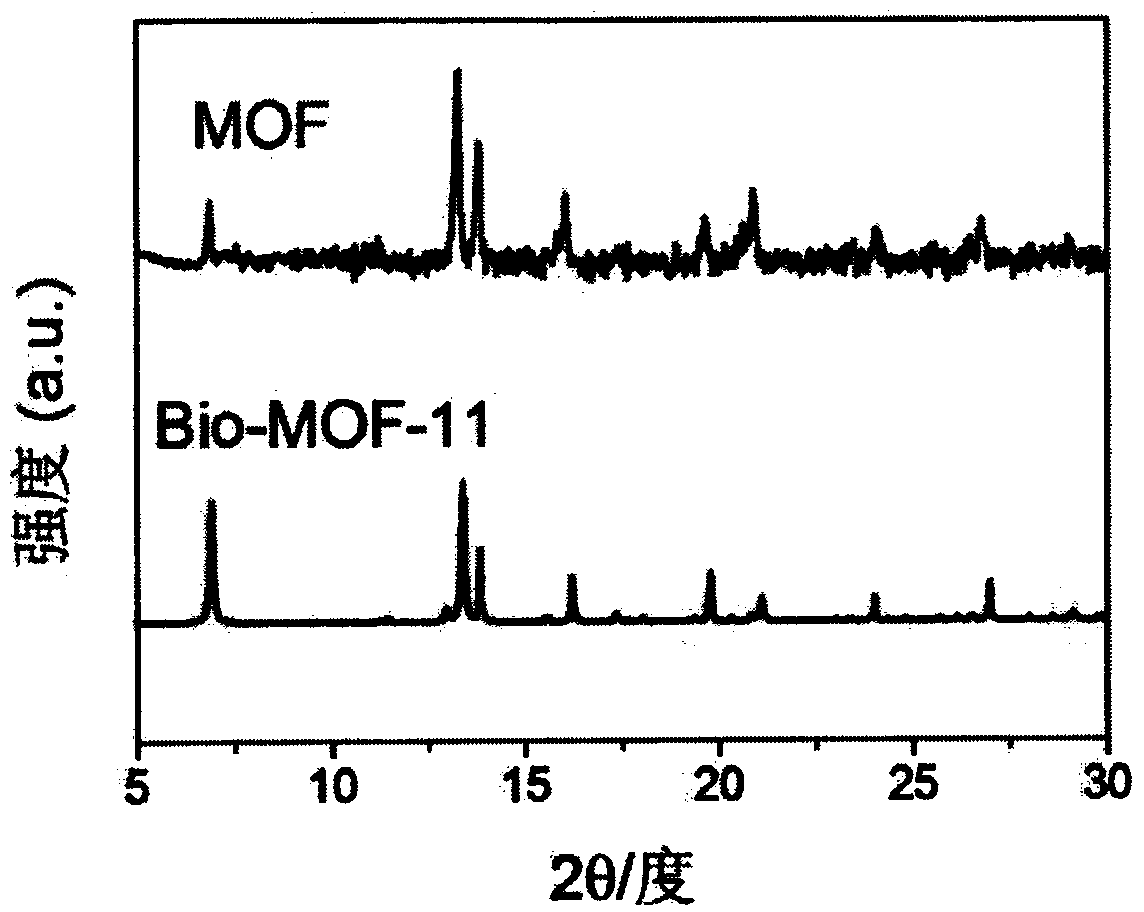

[0044] (1) XRD results showed that the synthesized MOF was indeed Bio-MOF-11. ( figure 1 )

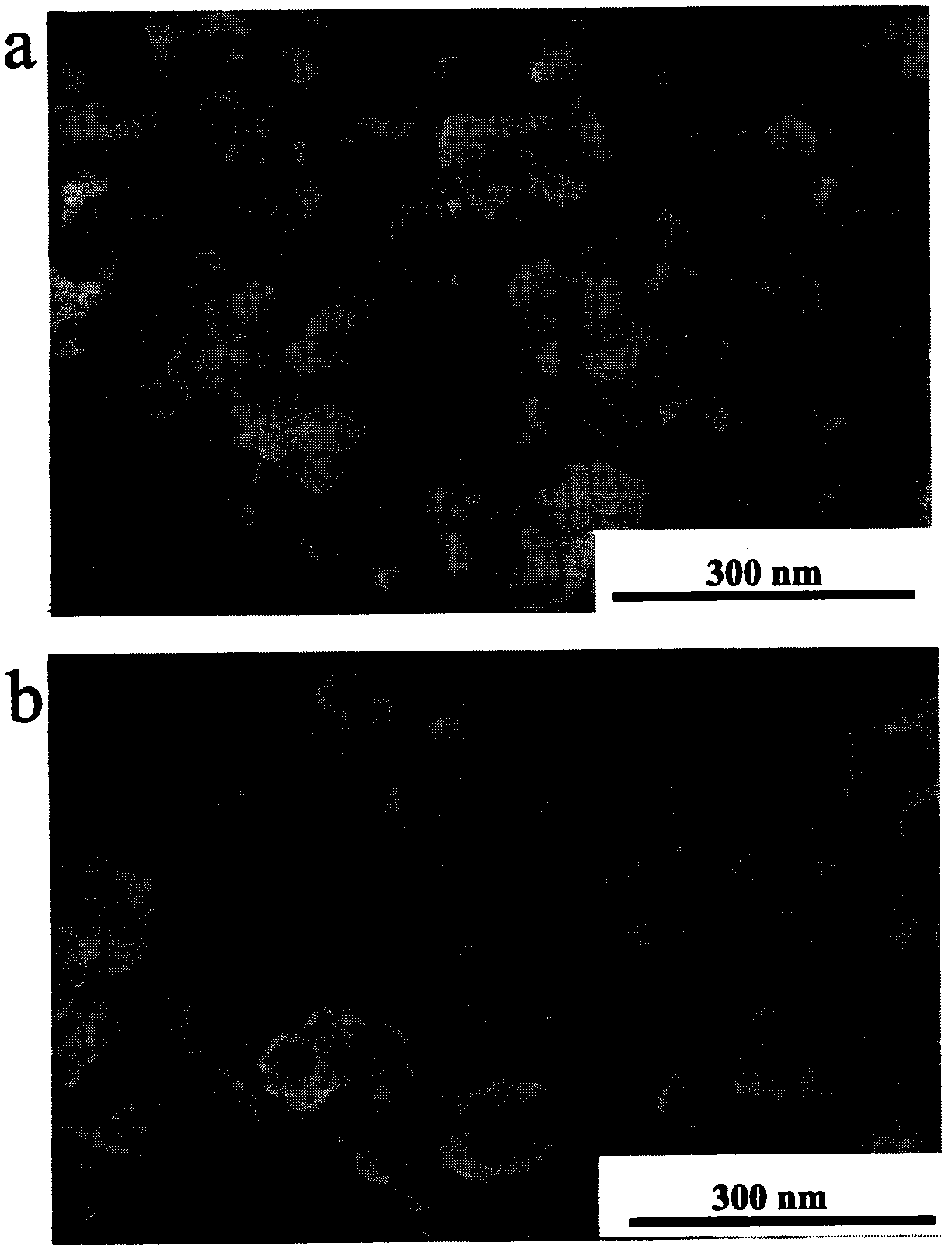

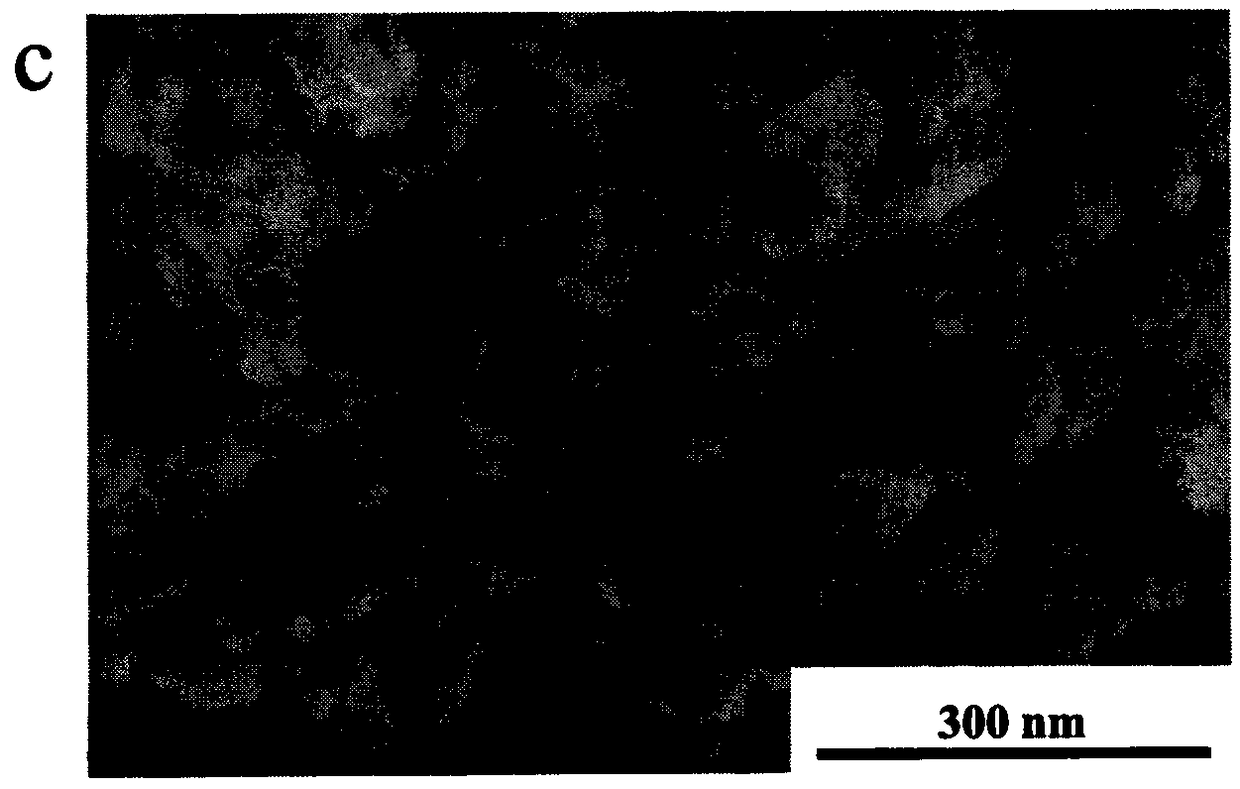

[0045] (2) SEM test results show that the Co-N-C composite material prepared in the present invention is the morphology of carbon nanospheres in situ grown carbon tubes after MOF carbonization, and as the calcination temperature increases, the aggregated form becomes more and more serious. ( figure 2 )

[0046] (3) TEM test results show that in the Co-N-C composite material prepared in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com