Polymeric aluminum ferric chloride sulfate flocculating agent and preparation method thereof

A technology of polychlorinated sulfuric acid and flocculant, applied in the fields of ferric sulfate, chemical instruments and methods, flocculation/sedimentation water/sewage treatment, etc. , complex processing technology and other problems, to achieve the effect of short floc settling time, reducing environmental pollution and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A kind of preparation method of polymerized ferric aluminum sulphate chloride flocculant, comprises the following steps:

[0037] (1) Add hydrochloric acid to titanium dioxide industrial by-products containing sulfuric acid 22.8-28.17% and ferrous sulfate 6.65-8.82%, and heat to 40-50°C for modification reaction to obtain modified titanium dioxide industrial by-products.

[0038](2) Mix and heat red mud iron extraction slag containing 6.35-8.66% of alumina and 55.1-68.3% of iron oxide and modified titanium dioxide industrial by-product to 100-110° C. to react to obtain a mixed solution.

[0039] (3) Cooling and filtering the mixed solution, and adding an oxidizing agent to the obtained filtrate to carry out polymerization reaction.

[0040] Among the above-mentioned titanium dioxide industrial by-products: the specific content of sulfuric acid can be listed as 22.8%, 23.5%, 25.35%, 26.68% or 28.17% etc.; the specific content of ferrous sulfate can be listed as 6.65%, 7....

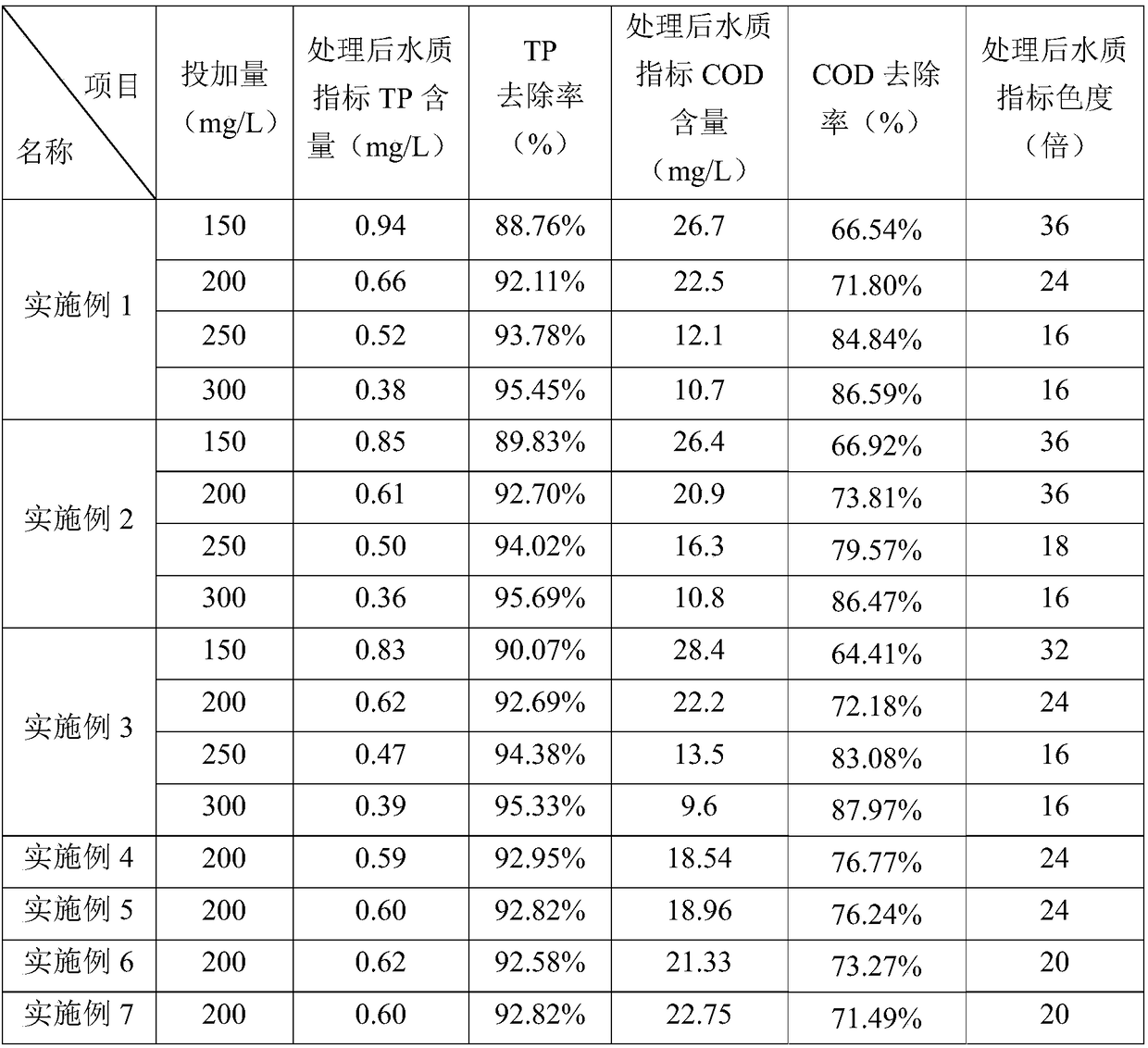

Embodiment 1

[0059] (1) Add 8mol / L industrial hydrochloric acid to titanium dioxide industrial by-products containing 22.8% sulfuric acid and 8.82% ferrous sulfate, and heat to 40°C for 40 minutes to obtain modified titanium dioxide industrial by-products; The mass ratio of hydrochloric acid to the titanium dioxide industrial by-product is 1:8.

[0060] (2) Add the red mud iron extraction slag containing 6.35% of alumina and 68.3% of iron oxide and the modified titanium dioxide industrial by-product prepared in step (1) into an ultrasonic reactor to mix and heat to 100° C., and react for 100 minutes, A mixed solution is obtained; the mass ratio of the iron extraction slag from the red mud and the modified titanium dioxide industrial by-product is 12:82.

[0061] (3) Cool the mixed solution prepared in step (2) to 80-85°C and filter, then add oxidant potassium chlorate to the obtained filtrate, stir at the same time to allow oxidation and polymerization to proceed, and stir for 15 minutes t...

Embodiment 2

[0063] (1) Add 8.5mol / L industrial hydrochloric acid to titanium dioxide industrial by-products containing 23.5% sulfuric acid and 8.25% ferrous sulfate, and heat to 45°C for 40 minutes to obtain modified titanium dioxide industrial by-products; The mass ratio of industrial hydrochloric acid to the titanium dioxide industrial by-product is 1:8.5.

[0064] (2) Add the red mud iron extraction slag containing 6.86% of alumina and 65.6% of iron oxide and the modified titanium dioxide industrial by-product prepared in step (1) into an ultrasonic reactor to mix and heat to 105° C., react for 90 minutes, A mixed liquor is obtained; the mass ratio of the iron extraction slag from the red mud and the modified titanium dioxide industrial by-product is 13:85.

[0065] (3) Cool the mixed solution prepared in step (2) to 80-85°C and filter, then add oxidant potassium chlorate to the obtained filtrate, stir at the same time to allow oxidation and polymerization to proceed, and stir for 20 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com