Long-chain branching polymer-type processing aid and preparation method and application thereof

A processing aid and long-chain branching technology, which is applied in the field of long-chain branched polymer processing aids and their preparation, can solve the problem of poor controllability of product structure, difficulty in feasibility, reduction of biodegradability and thermoplasticity Processing performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

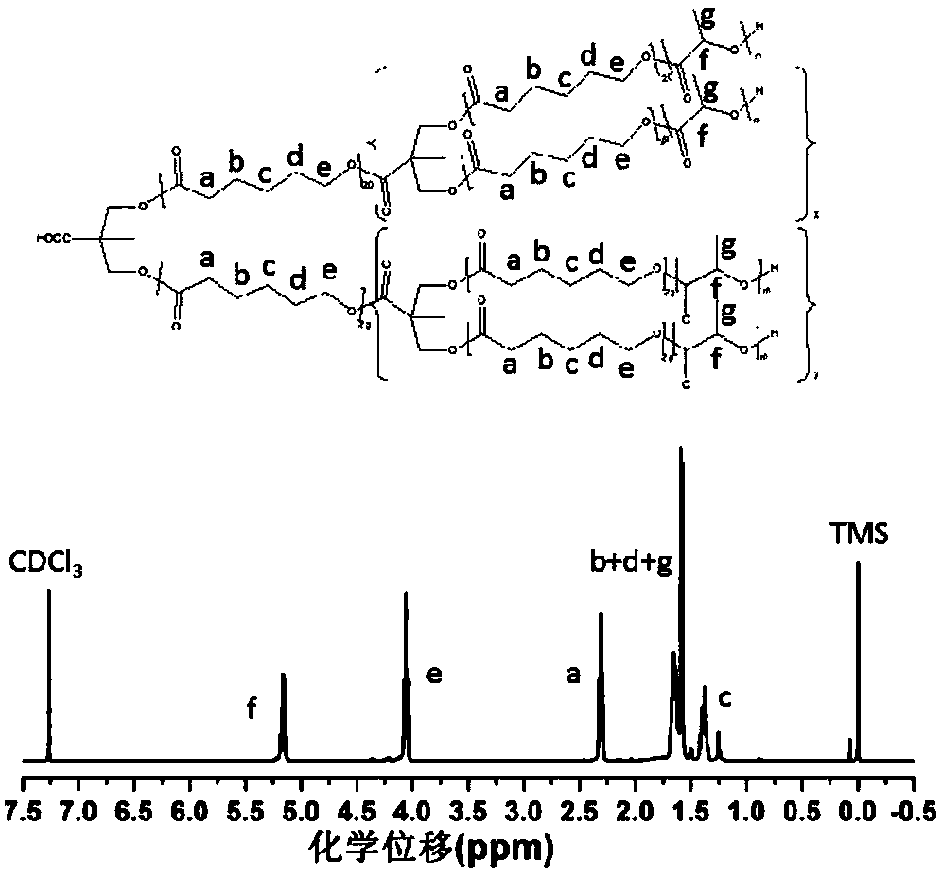

[0071] Under the protection of nitrogen, feed bismethylolpropionic acid and caprolactone at a molar ratio of 1:40, then add the catalyst stannous octoate at a molar ratio of 1:1000 to caprolactone, and react at 120°C After 48 hours, the crude product was obtained after cooling, and the obtained crude product was purified and then dried to obtain the soft segment polyester. Its structural formula is as follows:

[0072]

[0073] Under the protection of nitrogen, react at 200°C for 4h, then feed the catalyst tetrabutyl titanate and the above-mentioned soft segment polyester at a mass ratio of 1:300, and react for 4h at a vacuum degree of 100Pa and a temperature of 220°C. After cooling, the crude product is obtained, and the obtained crude product is purified and dried to obtain a long-chain branched soft segment polyester, and its structural formula is as follows:

[0074]

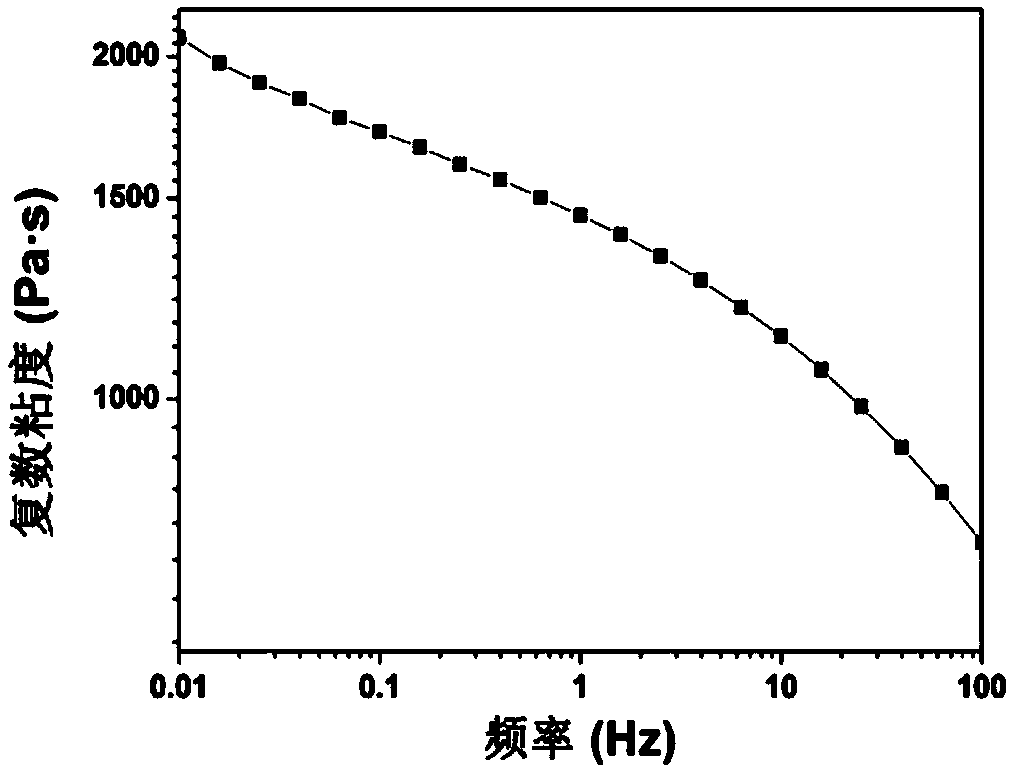

[0075] Under the protection of nitrogen, the above-mentioned long-chain branched soft segment polye...

Embodiment 2

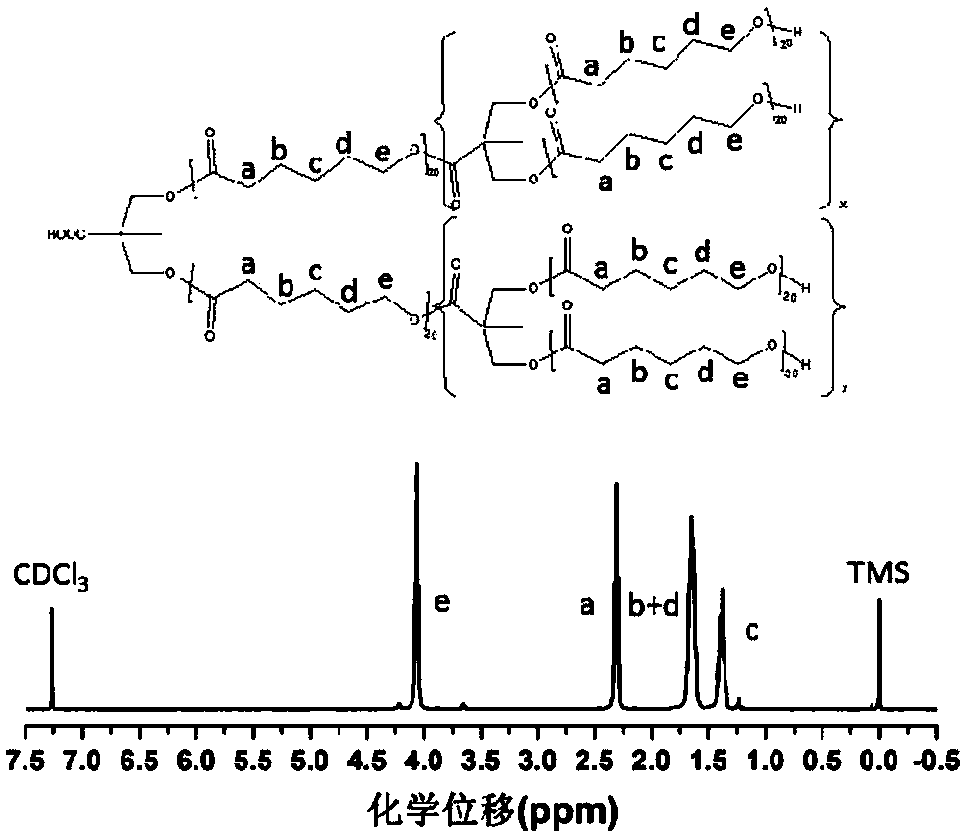

[0079] Under the protection of nitrogen, feed bismethylolpropionic acid and caprolactone at a molar ratio of 1:60, then add the catalyst stannous octoate at a molar ratio of 1:1000 to caprolactone, and react at 120°C After 48 hours, the crude product was obtained after cooling, and the obtained crude product was purified and then dried to obtain the soft segment polyester.

[0080] Under the protection of nitrogen, react at 200°C for 4h, then feed the catalyst tetrabutyl titanate and the above-mentioned soft segment polyester at a mass ratio of 1:300, and react for 4h at a vacuum degree of 100Pa and a temperature of 220°C. After cooling, a crude product is obtained, which is purified and then dried to obtain a long-chain branched soft segment polyester.

[0081] Under the protection of nitrogen, the above-mentioned long-chain branched soft segment polyester and L-lactide are fed in a mass ratio of 3:2, and then the catalyst octanoic acid is added in a molar ratio of 1:500 to l...

Embodiment 3

[0083] Under the protection of argon, feed 3,5-cis-dihydroxyheptanoic acid and γ-butyrolactone at a molar ratio of 1:200, and then add octanoic acid as a catalyst at a molar ratio of 1:2000 to caprolactone Stannous, reacted at 90°C for 60 hours, and obtained a crude product after cooling. The obtained crude product was purified and then dried to obtain a soft segment polyester.

[0084] Under the protection of argon, react at 240°C for 2h, then feed the catalyst tetrabutyl titanate and the above soft segment polyester at a mass ratio of 1:200, and react for 1h at a vacuum degree of 20Pa and a temperature of 250°C After cooling, a crude product is obtained, and the obtained crude product is purified and then dried to obtain a long-chain branched soft segment polyester.

[0085] Under the protection of argon, feed the above-mentioned long-chain branched soft segment polyester and L-lactide in a mass ratio of 3:2, and then add a catalyst with a molar ratio of 1:100 to lactide St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com