Process for producing hydrocarbon oil by performing supercritical hydrothermal treatment on waste plastic and straws

A technology for supercritical water and waste plastics, which is used in the treatment of hydrocarbon oil, the preparation of liquid hydrocarbon mixtures, and the petroleum industry. Easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

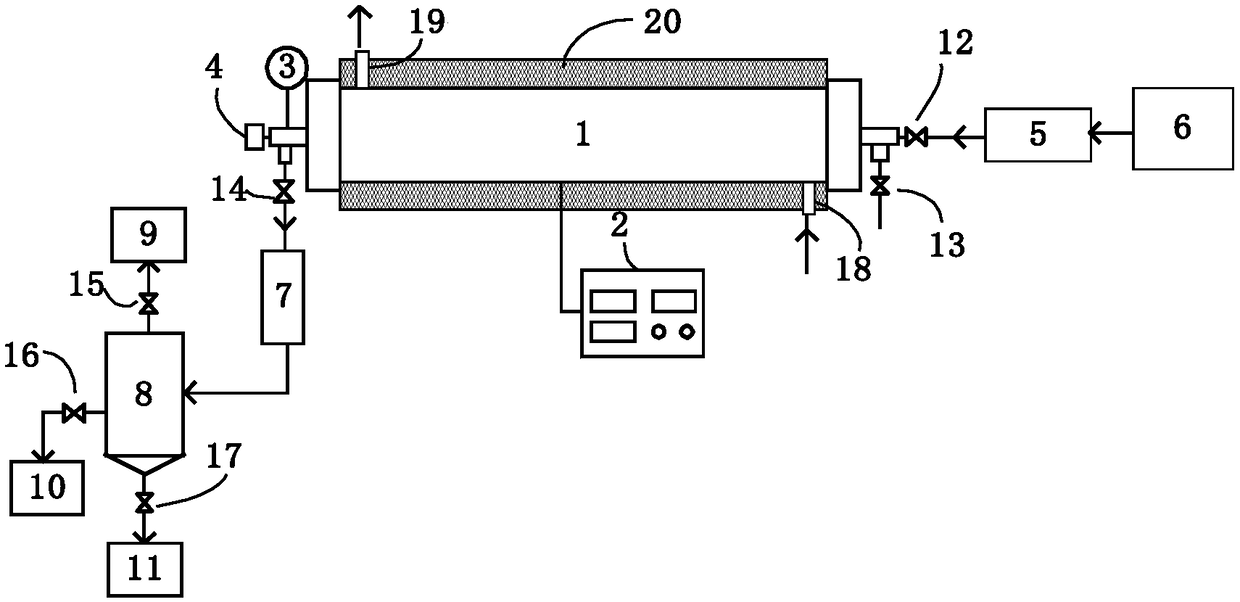

[0029] This embodiment adopts figure 1 Shown reaction device, this device is connected feed pump 5, heat exchange unit 7, phase separator 8, gas storage tank 9, liquid storage tank 10 and residual oil storage tank 11 by horizontal tube reactor 1. composition. The reactor is 60cm long and 12cm in diameter, and 7 reaction tubes are arranged in the reactor, and the diameter of the reaction tubes is 2cm. One end of the reactor is connected to the screw pump 5 through the valve 12 , the other end of the reactor is connected to the heat exchange unit 7 through the valve 14 , and the heat exchange unit is connected to the gas-liquid separator 8 .

[0030] Grinding the transparent PE pipe and corn cob, mixing the crushed plastic and corn cob according to the mass ratio of 5:1 to obtain the mixed raw material, mixing the pulverized mixed raw material and distilled water in the raw material mixing tank 6 to form a slurry material, and mixing the water and The mass ratio of raw materia...

Embodiment 2

[0032]The reaction device used in this embodiment is the same as in Example 1. Grinding the PP film and corn stalks, mixing the crushed plastic and corn stalks at a mass ratio of 1:1 to obtain a mixed raw material, mixing the crushed mixed raw material and distilled water in the raw material mixing tank 6 to form a slurry material, water and mixed raw material The mass ratio is 1:1. The slurry state material is sent into the tube side of the reactor 1 with a screw pump 5, and the reactor is sealed. Circulate the molten salt on the shell side of the reactor to heat the reaction tube, and heat the reactor in two steps. The first step is to heat to 250°C and maintain a constant temperature for 20 minutes. The second step is to raise the temperature to 420°C, and the reaction is carried out for 20 minutes. The pressure inside the tube is self-generated pressure. After the reaction is over, open the valve 14 quickly, and use the pressure inside the reactor to quickly discharge th...

Embodiment 3

[0034] The reaction device used in this embodiment is the same as in Example 1. Grinding the transparent PS lunch box and sorghum stalks, mixing the crushed plastic and sorghum stalks at a mass ratio of 1:5 to obtain mixed raw materials, mixing the crushed mixed raw materials and distilled water in the raw material mixing tank 6 to form a slurry material, water and The mass ratio of the mixed raw materials is 1:2. The slurry state material is sent into the tube side of the reactor 1 with a screw pump 5, and the reactor is sealed. Circulate the molten salt on the shell side of the reactor to heat the reaction tube, and heat the reactor in two steps. The first step is to heat to 200°C and keep it constant for 30 minutes. The second step is to raise the temperature to 430°C, and the reaction is carried out for 10 minutes. The pressure inside the tube is self-generated pressure. After the reaction is over, open the valve 14 quickly, and use the pressure inside the reactor to qui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com