A kind of two-dimensional perovskite single crystal material and preparation method thereof

A single crystal material and perovskite technology, which is applied in polycrystalline material growth, single crystal growth, single crystal growth, etc., can solve the problem of long period of two-dimensional perovskite, unfavorable formation of large-sized single crystal, and limited preparation efficiency and other problems, to achieve the effect of low environmental water and oxygen requirements, good application prospects, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

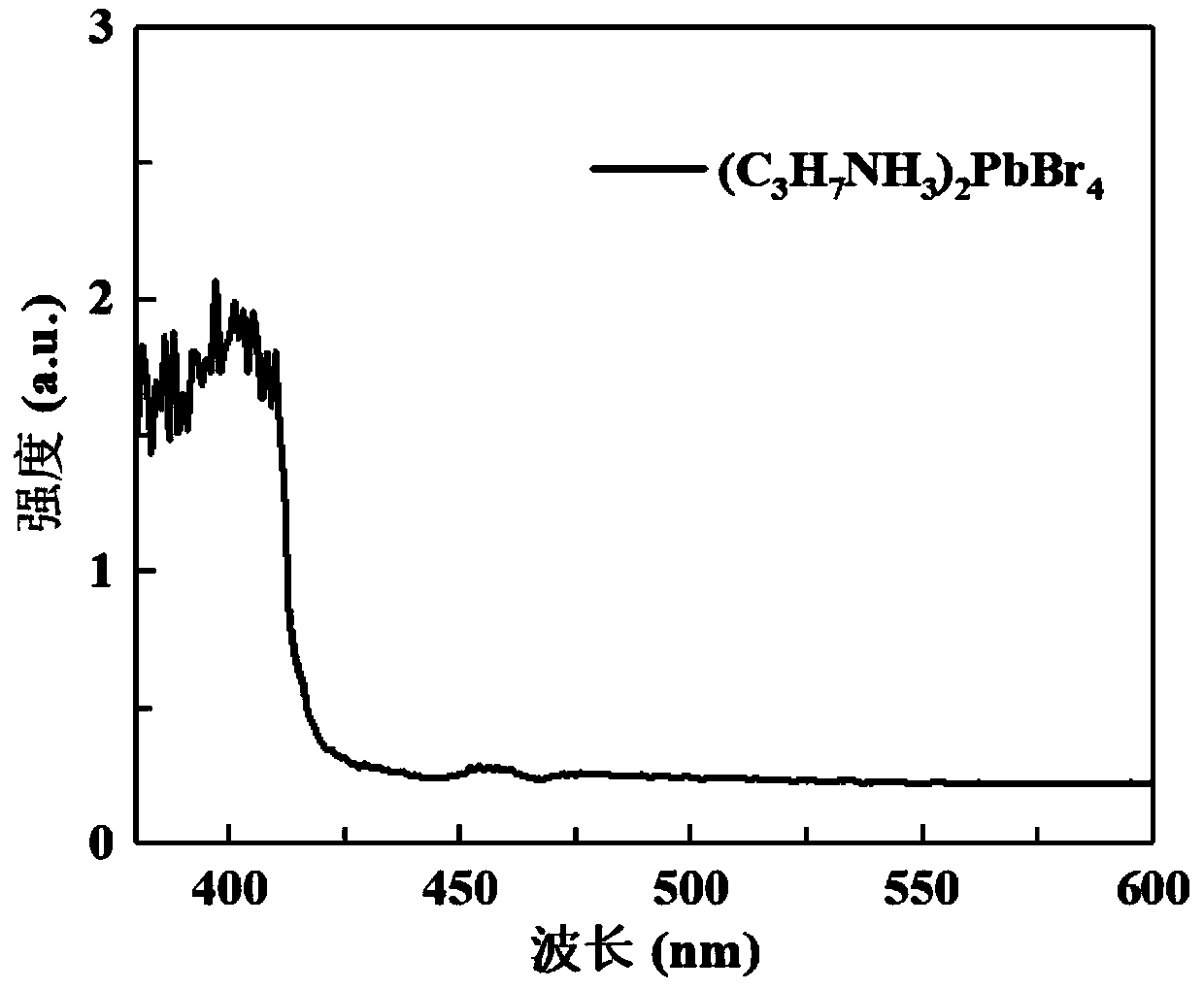

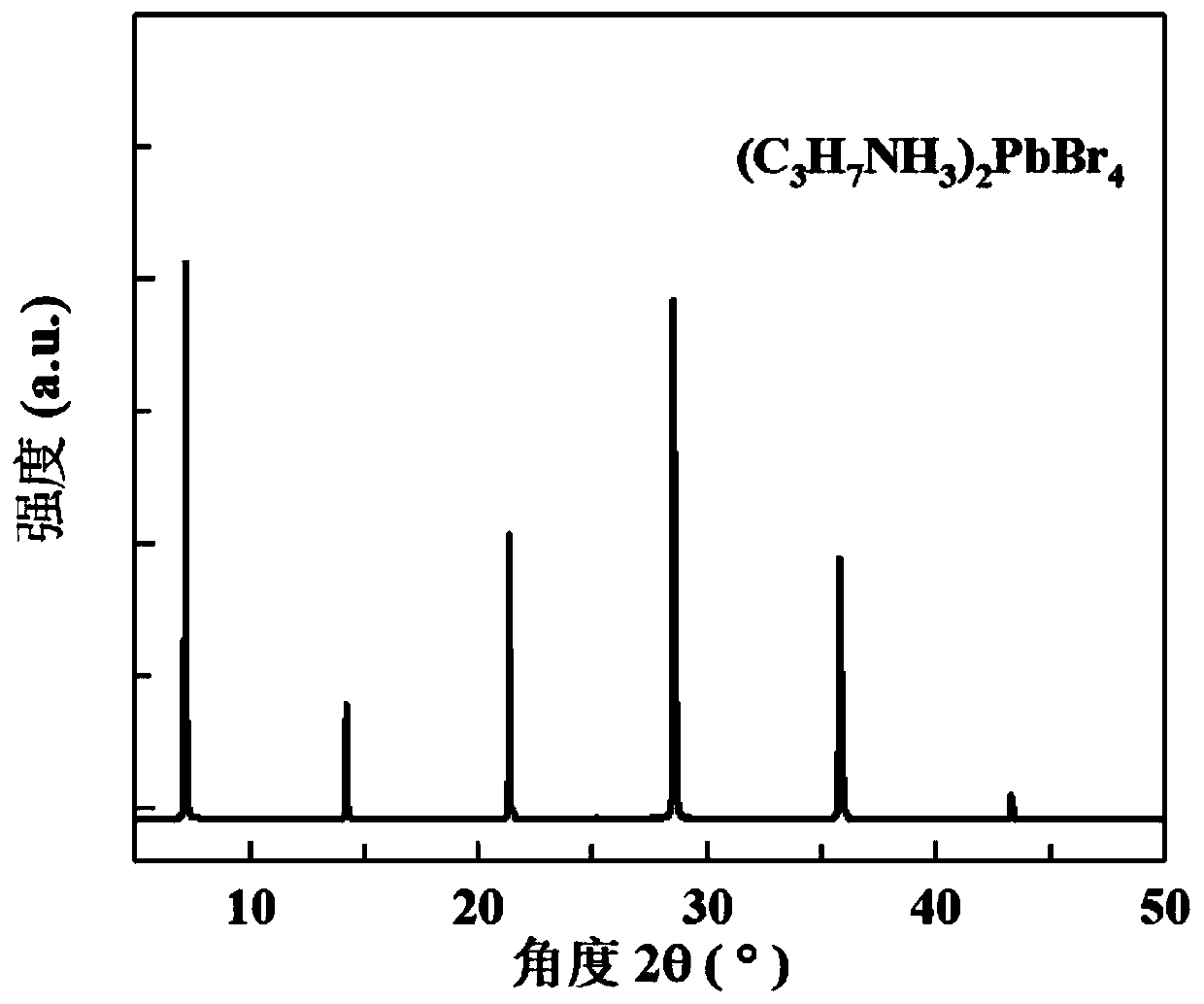

[0030] Lead bromide and propyl ammonium bromide (C 3 h 7 NH 3 Br) was added to the dimethylformamide solvent at a molar ratio of 1:2, and dissolved at room temperature to obtain a precursor solution with a solution concentration of 2M (mol / L); filter the precursor solution and put it into a clean 5mL In the sample bottle, add chlorobenzene solution (chlorobenzene: acetonitrile = 1:0) into another 100mL wide-mouth bottle as an anti-solvent for preparing single crystal; put the 5mL sample bottle containing the precursor solution into the wide-mouth Inside the jar, seal the jar and place it in a quiet place at room temperature. After about 4 weeks, white transparent crystals were separated out in the sample bottle, and the obtained crystals were dried at a dry temperature and stored in a drying cabinet. By using an anti-solvent (chlorobenzene), we found that the larger the concentration of the precursor, the smaller the crystal size (less than 500 μm), the time to obtain the c...

Embodiment 2

[0032] Add lead bromide and propyl ammonium bromide into dimethylformamide solvent at a molar ratio of 1:2, and dissolve at room temperature to obtain a precursor solution with a concentration of 2M; filter the precursor solution and put it in In a clean 5mL sample bottle, add a mixed solution of chlorobenzene and acetonitrile (chlorobenzene:acetonitrile=1:0.1) in another 100mL wide-mouth bottle as an anti-solvent for preparing a single crystal; open the sample bottle containing the precursor solution Put it into the jar, seal the jar, and place it in a quiet room temperature environment. After about 24 hours, white transparent crystals will precipitate out of the jar. Dry the obtained crystals at a dry temperature and store them in a drying cabinet. By adding a small volume of acetonitrile to the mixed anti-solvent, we found that the concentration of the precursor solution is higher, and the time to prepare the crystal is shorter, but there are more crystal nuclei, the crysta...

Embodiment 3

[0034]Add lead bromide and propyl ammonium bromide into dimethylformamide solvent at a molar ratio of 1:2, and dissolve at room temperature to obtain a precursor solution with a concentration of 1.5M; filter the precursor solution and put into a clean 5mL sample bottle, and in another 100mL jar, add a mixed solution of chlorobenzene and acetonitrile (chlorobenzene:acetonitrile=1:0.1) as an anti-solvent for preparing a single crystal; the sample bottle containing the precursor solution Open the mouth and put it in the jar, seal the jar, and place it in a quiet room temperature environment. After about 48 hours, white transparent crystals will be precipitated in the sample bottle. Dry the obtained crystals at a dry temperature and store them in a drying cabinet for subsequent use. By adding a small amount of acetonitrile to the mixed anti-solvent, the time to prepare crystals is relatively short, the formation of crystal nuclei is relatively small, the crystal size is relatively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com