Assembly type overhead thermal insulation and sound insulation board for floating construction floor and preparing method of assembly type overhead thermal sound insulation board

A floating floor slab and prefabricated technology, applied in thermal insulation, sound insulation, building components, etc., can solve problems such as unguaranteed construction quality, weak bonding between flexible panels and fine stone concrete, maintenance, acceptance, and delivery troubles, etc. , to achieve the effect of saving labor and management costs, improving labor productivity and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

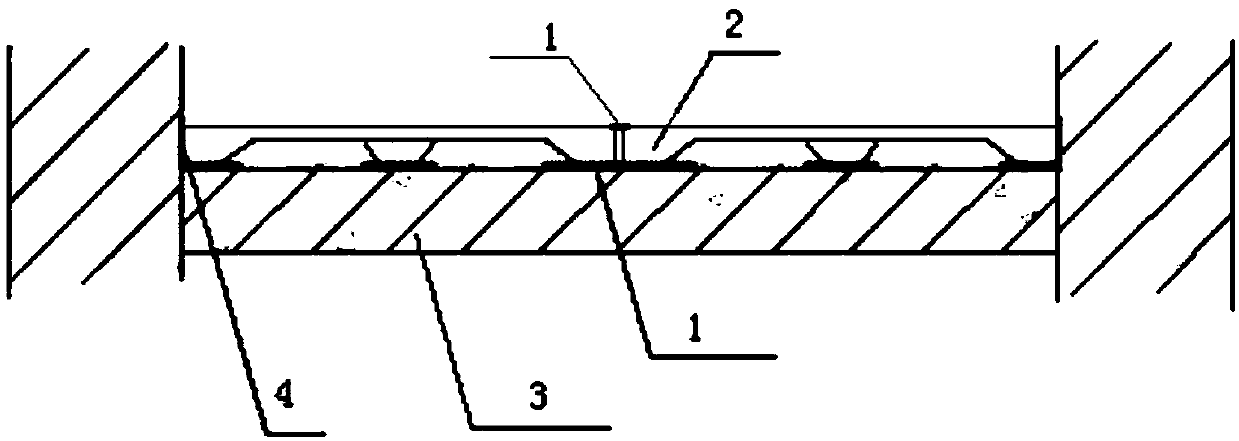

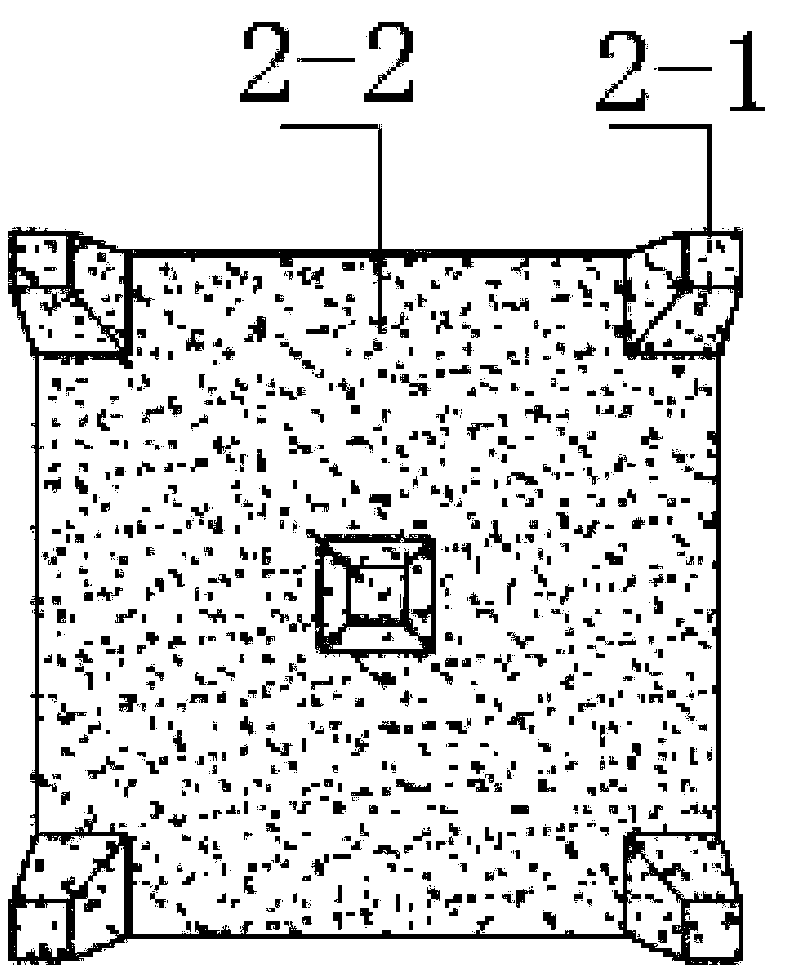

[0037] Such as figure 1 and 2Shown, a kind of prefabricated overhead heat insulation and sound insulation board for floating floor, it comprises the rapid-hardening cement mortar layer 1 on the household floor 3, the overhead load-bearing reinforced concrete slab 2 installed on the rapid-hardening cement mortar layer 1, The polyurethane foam layer sprayed on the back of the overhead load-bearing reinforced concrete slab 2;

[0038] The overhead load-bearing reinforced concrete slab 2 includes five supporting feet 2-1 at the bottom and a reinforced concrete slab 2-2 connected to the supporting feet 2-1, and the reinforced concrete slab 2-2 is provided with a steel mesh or mesh Gab. The bottom of the support foot 2-1 is bonded with a pure butyl rubber vibration damping pad.

[0039] Said floating floor slabs use prefabricated overhead heat insulation and sound insulation boards, and there is a gap of 5 to 10 mm between two adjacent overhead load-bearing reinforced concrete pa...

Embodiment 2

[0049] Such as figure 1 and 2 Shown, a kind of prefabricated overhead heat insulation and sound insulation board for floating floor, it comprises the rapid-hardening cement mortar layer 1 on the household floor 3, the overhead load-bearing reinforced concrete slab 2 installed on the rapid-hardening cement mortar layer 1, The inorganic mineral fiber thermal insulation and sound insulation material layer sprayed on the back of the overhead load-bearing reinforced concrete slab 2; the overhead load-bearing reinforced concrete slab 2 includes five supporting feet 2-1 at the bottom and reinforced concrete connected to the supporting feet 2-1 Slab 2-2, the reinforced concrete slab 2-2 is provided with reinforcement mesh or grid cloth. The bottom of the support foot 2-1 is bonded with a rubber vibration-damping pad.

[0050] Said floating floor slabs use prefabricated overhead heat insulation and sound insulation boards, and there is a gap of 5 to 10 mm between two adjacent overhea...

Embodiment 3

[0060] The preparation method of the prefabricated overhead thermal insulation and sound insulation board for floating floor slabs comprises the following steps:

[0061] (1) 500 parts by weight of Portland cement, 1000 parts by weight of regenerated sand and gravel aggregate, 500 parts by weight of non-burning slag ceramsite, 10 parts by weight of admixture, and 2 parts by weight of reinforcing fiber are stirred and transported to the mold of the hydroforming machine Inside, put steel mesh or grid cloth in the panel layer, and make a pentagonal overhead load-bearing reinforced concrete slab 2 after molding;

[0062] (2) After the pentagonal overhead load-bearing reinforced concrete slab 2 is naturally dried, on the conveying equipment assembly line, a special spraying machine is used to fully spray the foamed polyurethane thermal insulation layer on its back;

[0063] (3) After drying, paste a pure butyl rubber vibration damping pad on the bottom of the support foot 2-1 of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com