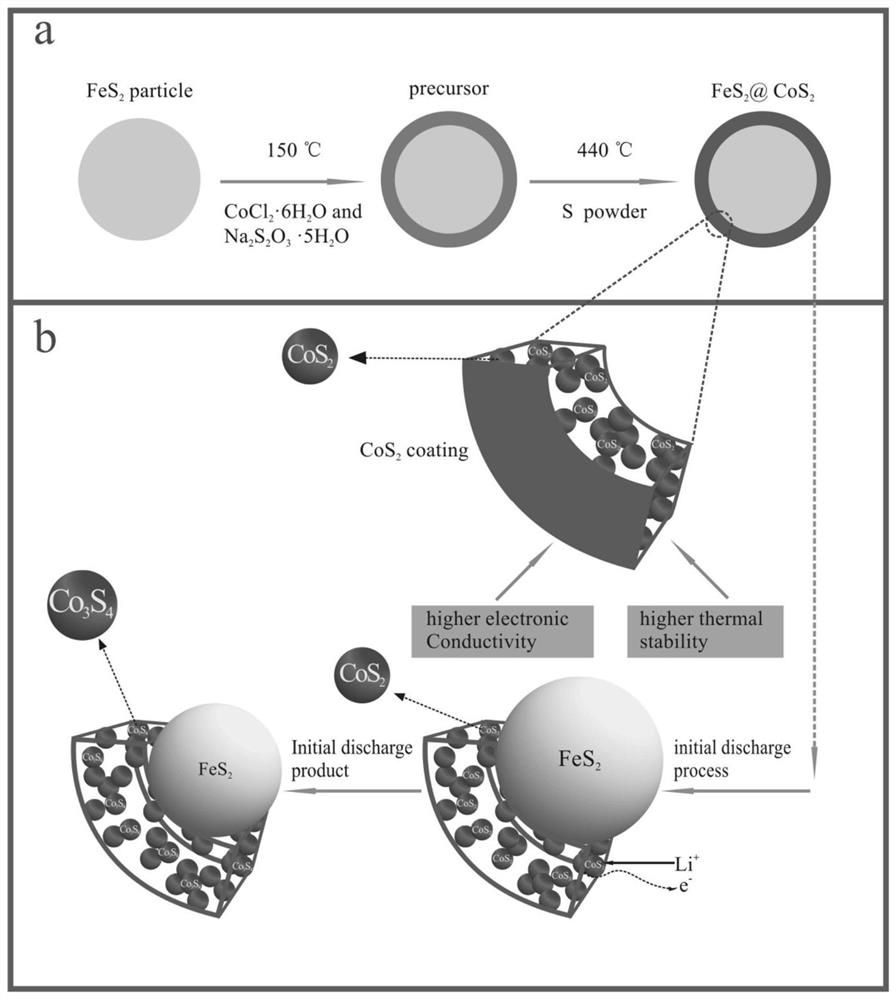

A kind of preparation method of core-shell composite sulfide material

A compound type, sulfide technology, applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems that cannot be completely eliminated, and achieve the effects of improved discharge voltage platform characteristics, increased room temperature conductivity, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

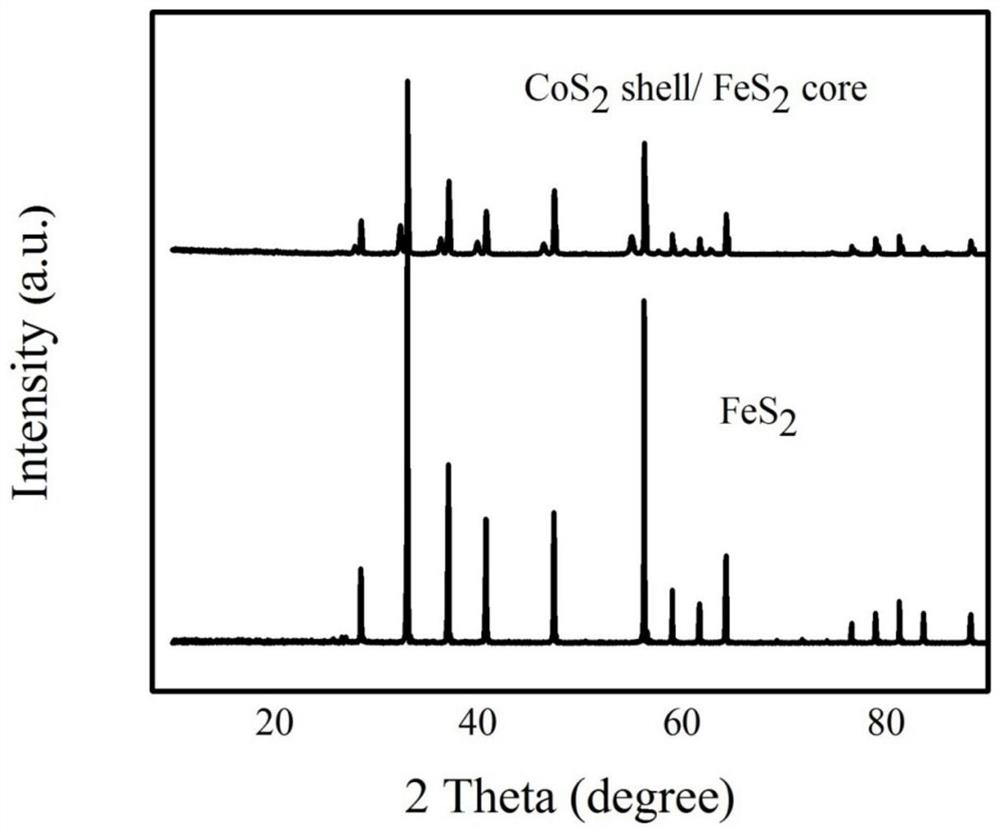

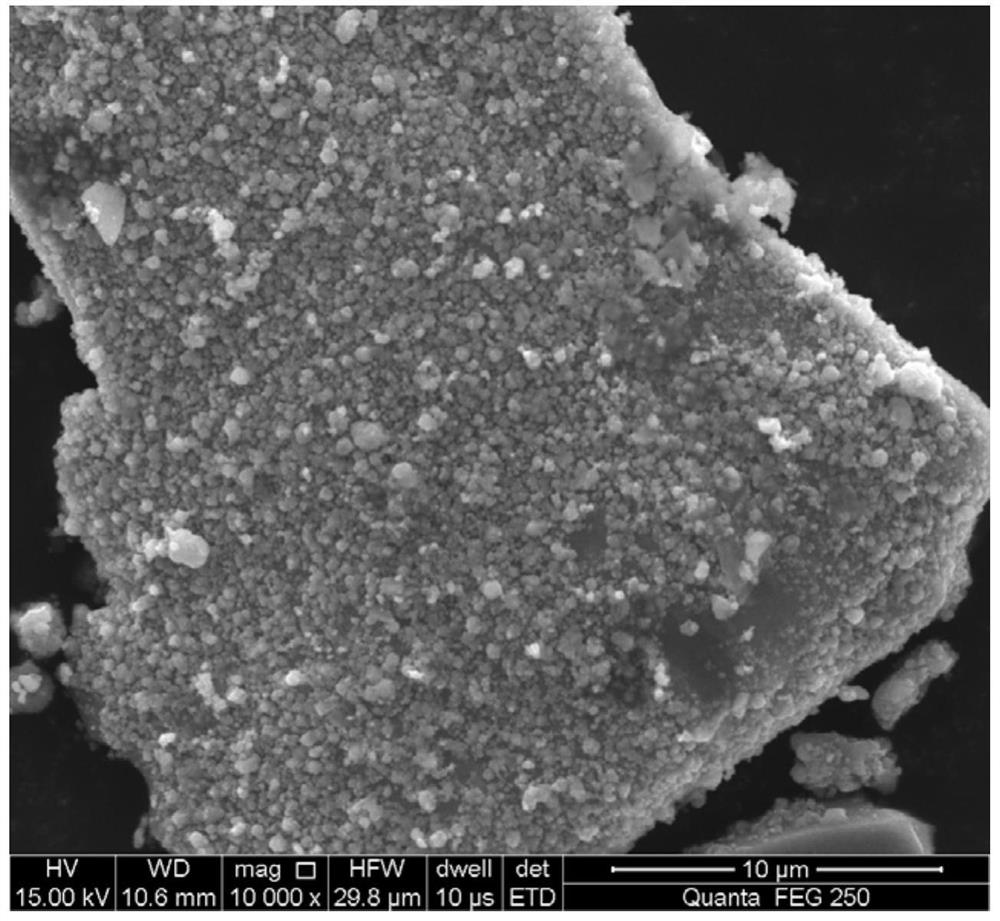

Method used

Image

Examples

Embodiment 1

[0042] CoCl 2 ·6H 2 O and Na 2 S 2 o 3 ·5H 2 15g (CoCl 2 ·6H 2 O and Na 2 S 2 o 3 ·5H 2 O), then add an appropriate amount of deionized water, then add 28g FeS 2 Powder (5.6-9.2 microns), transfer the mixture to an autoclave, set the heating and heat preservation program: the heating rate is 12°C / min, the heat preservation time is 10h, and the heat preservation temperature is 140°C. After heat preservation, the samples were cooled to room temperature with the furnace. Will get CoS 2 Coated FeS 2 The intermediate product of the positive electrode material, and then add 9g of sulfur powder to the intermediate product, and place it in a nitrogen-protected reaction furnace. During the reaction, the heating rate is 10°C / min, and it is raised to 400°C for 10h. Then the temperature was raised to 500°C at 12°C / min and kept for 15h. Then cool down to room temperature with the furnace to get the product.

[0043] The thermal battery single battery is made of the core-she...

Embodiment 2

[0045] CoCl 2 ·6H 2 O and Na 2 S 2 o 3 ·5H 2 20g (CoCl 2 ·6H 2 O and Na 2 S 2 o 3 ·5H 2 O), then add an appropriate amount of deionized water, then add an appropriate amount of 28g FeS 2 Powder (5.6-9.2 microns), transfer the mixture to an autoclave, set the heating and heat preservation program: the heating rate is 12°C / min, the heat preservation time is 10h, and the heat preservation temperature is 100°C. After heat preservation, the samples were cooled to room temperature with the furnace. Will get CoS 2 Coated FeS 2 The intermediate product of the positive electrode material, and then add 9g of sulfur powder to the intermediate product, and place it in a nitrogen-protected reaction furnace. During the reaction, the heating rate is 10°C / min, and it is raised to 400°C for 10h. Then the temperature was raised to 500°C at 12°C / min and kept for 15h. Then cool down to room temperature with the furnace to get the product.

[0046] The thermal battery single batter...

Embodiment 3

[0048] CoCl 2 ·6H 2 O and Na 2 S 2 o 3 ·5H 2 23g (CoCl 2 ·6H 2 O and Na 2 S 2 o 3 ·5H 2 O), then add an appropriate amount of deionized water, then add an appropriate amount of 28g FeS 2 Powder (5.6-9.2 microns), transfer the mixture to an autoclave, set the heating and heat preservation program: the heating rate is 12°C / min, the heat preservation time is 10h, and the heat preservation temperature is 145°C. After heat preservation, the samples were cooled to room temperature with the furnace. Will get CoS 2 Coated FeS 2 The intermediate product of the positive electrode material, and then add 9g of sulfur powder to the intermediate product, and place it in a nitrogen-protected reaction furnace. During the reaction, the heating rate is 10°C / min, and it is raised to 400°C for 12h. Then the temperature was raised to 500°C at 10°C / min and kept for 20h. Then cool down to room temperature with the furnace to get the product.

[0049] The thermal battery single batter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com