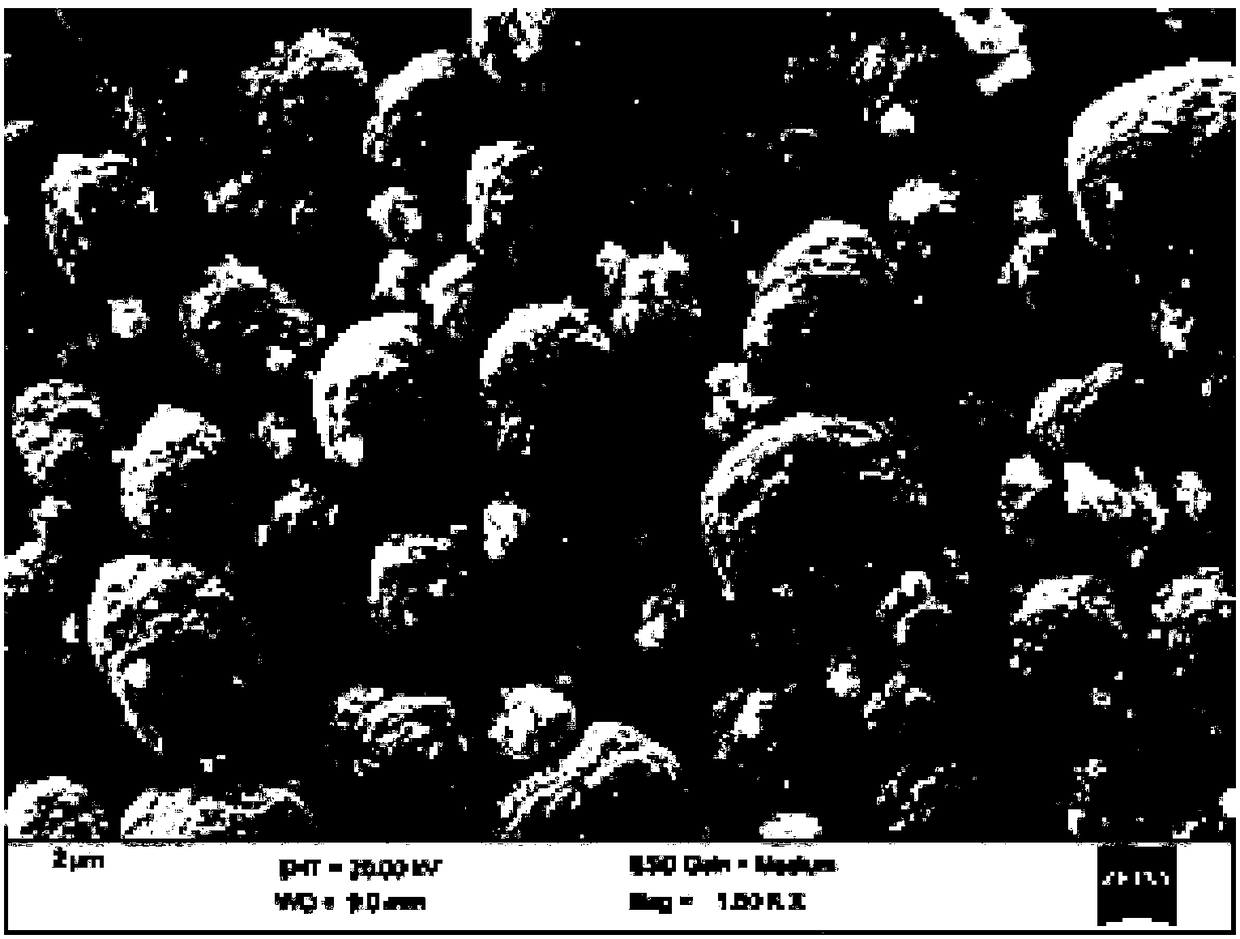

Method for preparing spherical Ni-Co-Mn ternary precursor by nitrogen-free complexing agent

A nickel-cobalt-manganese and complexing agent technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of difficult wastewater treatment, poor production environment, and high ammonia nitrogen content, so as to reduce the burden of pollution treatment and improve the production environment. , good effect of particle sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for assisting the preparation of spherical nickel-cobalt-manganese ternary precursors by a non-nitrogen-containing complexing agent, comprising the steps of:

[0034] Step a1, according to the molar ratio of nickel salt: cobalt salt: manganese salt=6:2:2, the nickel salt, cobalt salt, and manganese salt are prepared into a nickel-cobalt-manganese mixed salt solution with an overall concentration of metal ions of 2.0 mol / L.

[0035] Step b1, under the condition of high-speed stirring with a stirring speed of 600r / min, use a metering pump to separately mix the nickel-cobalt-manganese mixed salt solution, the sodium hydroxide solution with a concentration of 2.0mol / L and the lemon with a concentration of 0.5mol / L The sodium hydroxide solution is pumped into the sealed reaction kettle at the same time, and under the condition of nitrogen protection, the reaction temperature is controlled at 53-57°C, and the amount of sodium hydroxide solution is adjusted at the same...

Embodiment 2

[0039] A method for assisting the preparation of spherical nickel-cobalt-manganese ternary precursors by a non-nitrogen-containing complexing agent, comprising the steps of:

[0040] Step a2, according to the molar ratio of nickel salt: cobalt salt: manganese salt=6:2:2, the nickel salt, cobalt salt, and manganese salt are formulated into a nickel-cobalt-manganese mixed salt solution with an overall concentration of metal ions of 2.0 mol / L.

[0041] Step b2, under the condition of high-speed stirring with a stirring speed of 600r / min, use a metering pump to separately mix the nickel-cobalt-manganese mixed salt solution, the sodium hydroxide solution with a concentration of 2.0mol / L, and the glucose with a concentration of 0.8mol / L The sodium hydroxide solution is pumped into the sealed reaction kettle at the same time, and under the condition of nitrogen protection, the reaction temperature is controlled at 53-57°C, and the amount of sodium hydroxide solution is adjusted at the...

PUM

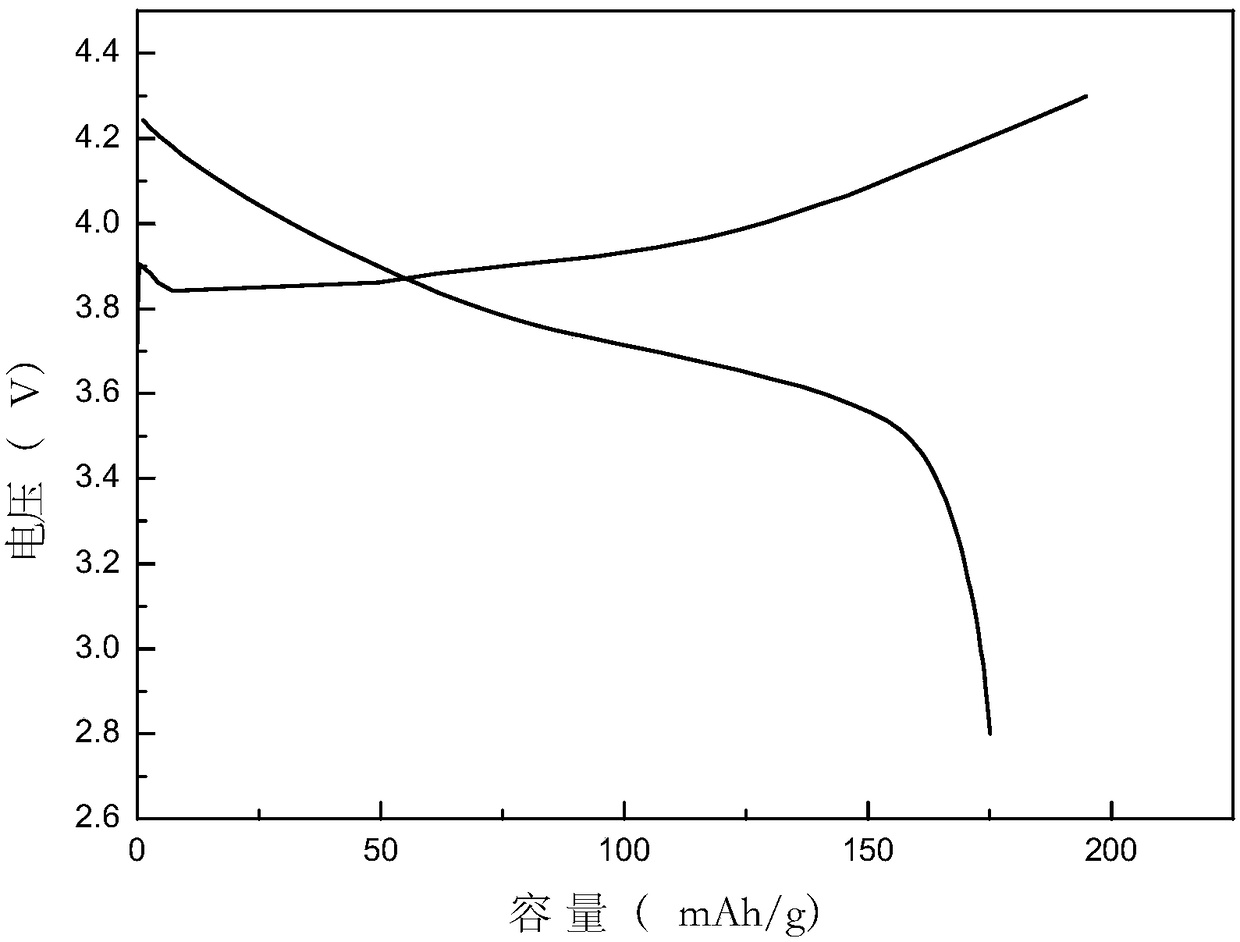

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com