Positively-symmetric double-Z-type sonocatalyst SnO2-CdSe-Bi2O3 and preparation method and application thereof

A catalyst and system technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as low transparency and photocatalysis, achieve stable properties, widen the response range, and inhibit separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

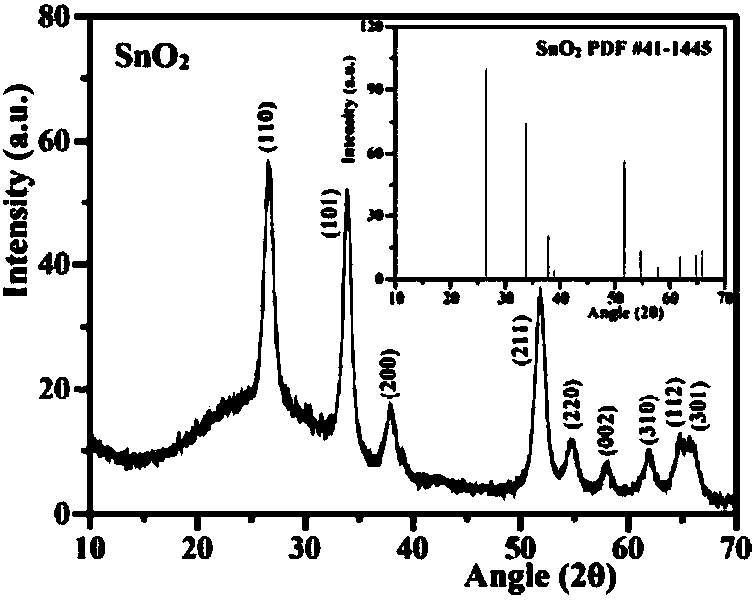

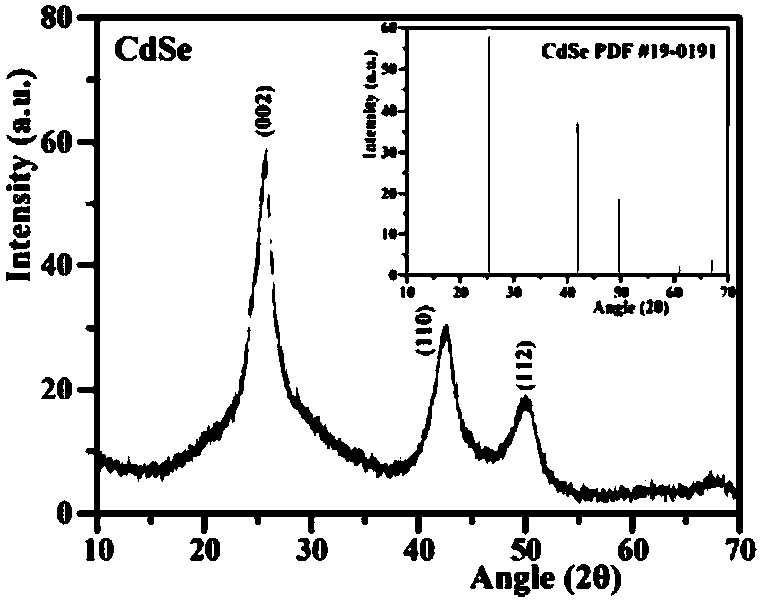

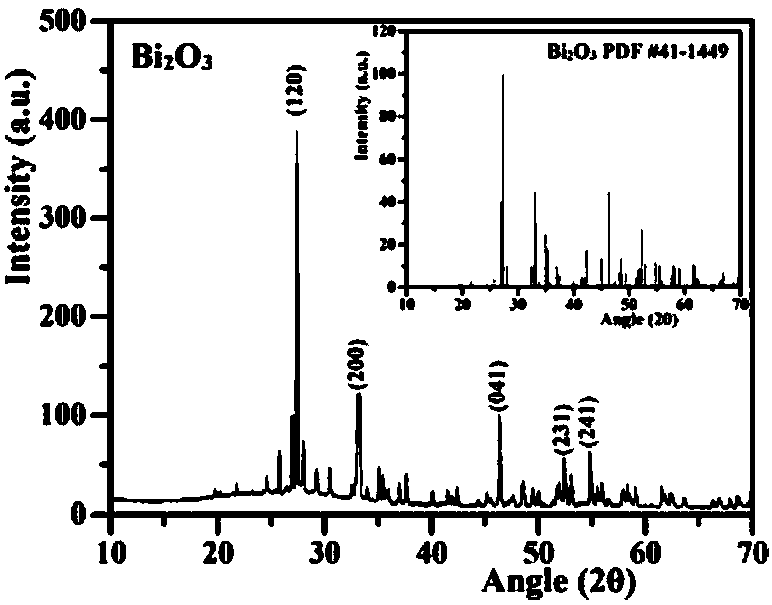

[0036] Example 1 Positive Symmetrical Double Z Type System Acoustic Catalyst SnO 2 –CdSe–Bi 2 o 3

[0037] (1) Preparation method

[0038] 1. Preparation of SnO 2 powder

[0039] 3mmol SnCl 4 ·5H 2 O was dissolved in a mixed solution of 45ml absolute ethanol and 5ml distilled water (volume ratio=9:1). Then put it into an autoclave and seal it, and heat it in an electric oven at 180°C for 12h. After the autoclave was naturally cooled to room temperature, it was centrifuged, and the obtained precipitate was washed several times with absolute ethanol and deionized water, dried at 60°C for 6 hours, and fully ground to obtain SnO 2 Powder, spare.

[0040] 2. Preparation of CdSe powder

[0041] 4g anhydrous sodium sulfite (Na 2 SO 3 ) and 0.2 g of selenium powder (Se) with 20 mL of distilled water were vigorously stirred at a constant temperature of 70 °C to form Na 2 SeSO 3 solution. In another reaction vessel, 2 mL of ammonium hydroxide solution (NH 4 OH) was added...

Embodiment 2

[0058] Example 2 Positive Symmetric Double Z Type System Acoustic Catalyst SnO 2 –CdSe–Bi 2 o 3 Application in Degradation of Organic Dyes Solution (1) Acoustic Catalyst SnO in Different Time Periods 2 –CdSe–Bi 2 o 3 The UV absorption spectrum of degraded rhodamine B and the change of degradation rate calculated based on UV-visible (UV-vis) and total organic carbon (TOC).

[0059] Experimental method: 0.2g SnO 2 –CdSe–Bi 2 o 3 And 200mL of 10.0mg / L rhodamine B aqueous solution. At a temperature of 25–28°C, 300W, 40KHz ultrasonic irradiation was used for 150min with an interval of 30min.

[0060] Since rhodamine B has double bonds and conjugated double bonds, the π→π* electronic transitions can be excited at matching wavelengths. In addition, there are some heteroatom double bonds containing lone pairs of electrons, and n→π* electron transitions will also occur. From Figure 5a It can be seen that there are absorption peaks at 553nm, 258nm and 352nm wavelengths. Amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com