Composite polypeptide protein powder solid beverage and production technology thereof

A technology of solid beverage and production process, applied in the field of protein powder, can solve problems such as inducing migraine, and achieve the effects of enhancing health care, low cost, and increasing diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

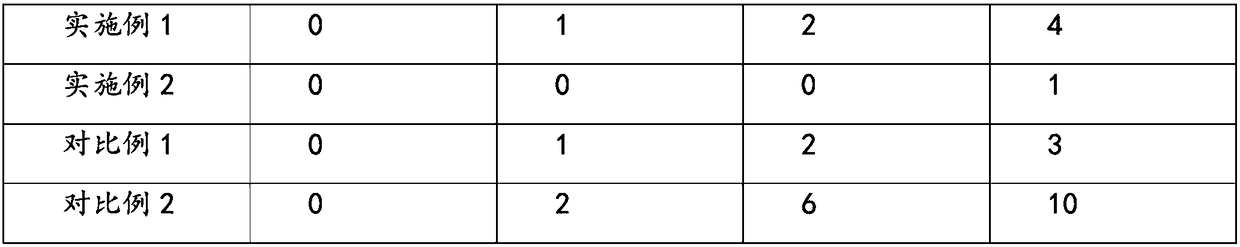

Embodiment 1

[0042]A composite polypeptide protein powder solid beverage, characterized in that: the composite polypeptide protein powder solid beverage comprises the following raw materials in parts by weight: 90-110 parts of milk powder, 440-460 parts of anhydrous glucose, lactoferrin 1-10 parts, 190-210 parts of whey protein powder, 1-10 parts of casein phosphopeptide, 40-60 parts of marine fish oligopeptide powder, 1-10 parts of taurine, fructooligosaccharide 90-110 parts, 90-110 parts of galacto-oligosaccharides, 1-10 parts of vitamin C, vitamin B 12 0.01~0.1 part, Vitamin B 6 0.01~0.1 part, Vitamin B 2 0.01-0.1 part, 0.1-1 part of zinc glycinate, 0.1-1 part of ferrous glycinate, 1-10 parts of calcium glycinate.

[0043] Its preparation method comprises the following steps:

[0044] 1) Crushing and sieving: receive qualified raw materials, crush and sieve;

[0045] 2) Batching, stirring, and granulation: Proportionately mix different types of raw materials, weigh the raw materials...

Embodiment 2

[0049] A composite polypeptide protein powder solid beverage, characterized in that: the composite polypeptide protein powder solid beverage includes the following raw materials in parts by weight: 110 parts of milk powder, 460 parts of anhydrous glucose, 10 parts of lactoferrin, whey protein 210 parts of powder, 10 parts of casein phosphopeptide, 60 parts of marine fish oligopeptide powder, 10 parts of taurine, 110 parts of fructo-oligosaccharide, 110 parts of galacto-oligosaccharide, 10 parts of vitamin C, vitamin B 12 0.1 parts, Vitamin B 6 0.1 parts, Vitamin B 2 0.1 part, 1 part of zinc glycinate, 1 part of ferrous glycinate, 10 parts of calcium glycinate.

[0050] Its preparation method comprises the following steps:

[0051] 1) Crushing and sieving: receive qualified raw materials, crush and sieve;

[0052] 2) Batching, stirring, and granulation: Proportionately mix different types of raw materials, weigh the raw materials one by one, pour the weighed raw materials in...

Embodiment 3

[0056] A composite polypeptide protein powder solid beverage, characterized in that: the composite polypeptide protein powder solid beverage includes the following raw materials in parts by weight: 100 parts of milk powder, 450 parts of anhydrous glucose, 1 part of lactoferrin, whey protein 200 parts of powder, 1.6 parts of casein phosphopeptide, 50 parts of marine fish oligopeptide powder, 1.4 parts of taurine, 100 parts of fructo-oligosaccharide, 100 parts of galacto-oligosaccharide, 2.25 parts of vitamin C, 0.022 parts of vitamin B120 , 0.022 parts of vitamin B6, 0.022 parts of vitamin B2, 0.5 parts of zinc glycinate, 0.6 parts of ferrous glycinate, and 2 parts of calcium glycinate.

[0057] Its preparation method comprises the following steps:

[0058] 1) Crushing and sieving: receive qualified raw materials, crush and sieve;

[0059] 2) Batching, stirring, and granulation: Proportionately mix different types of raw materials, weigh the raw materials one by one, pour the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com