Alginate microsphere encapsulating Bi2S3 nanoparticles and preparation method thereof

An alginate and nanoparticle technology, applied in nanotechnology, nanotechnology, nanomedicine and other directions, can solve the problems of harsh preparation conditions and complicated preparation process of nanoparticles, and achieve controllable particle size of microspheres, simple preparation process, Promising effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

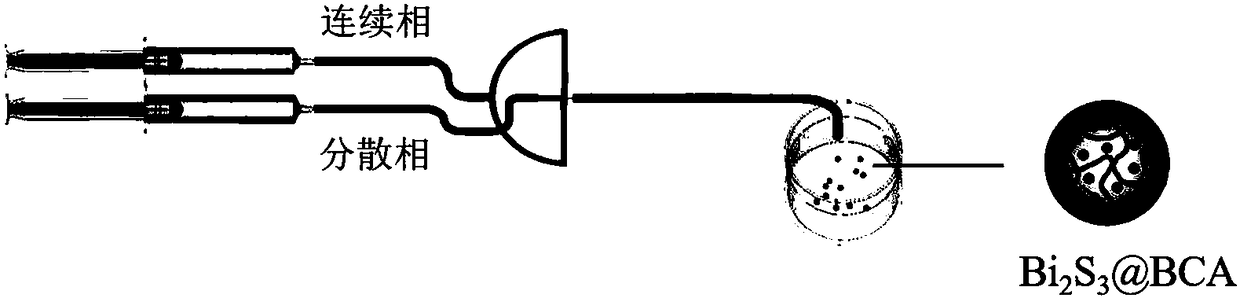

[0052] This embodiment provides a kind of encapsulation Bi 2 S 3 The preparation method of the alginate microsphere of nanoparticle, its flow chart is as figure 1 shown, including the following steps:

[0053] (1) Preparation of oil phase (continuous phase): weigh 0.008g anhydrous CaCl 2 Add it into 4mL ethanol, ultrasonically dissolve or stir to dissolve, then add it into 10mL liquid paraffin containing 2.0wt% Span80, stir for 3 hours to mix, and then magnetically stir in a 60°C water bath to completely volatilize the ethanol until the solution changes from turbid to For clarification, after cooling to room temperature, the oil phase containing calcium salt nanoparticles formed in situ is obtained;

[0054] (2) Preparation of water phase (dispersed phase): first prepare 2.0wt% sodium alginate aqueous solution, then add Na 2 S 2 o 3 , so that Na 2 S 2 o 3 The concentration is 0.15mol / L, which is the water phase;

[0055] (3) Preparation of Bi 3+ and Ca 2+ Acid rece...

Embodiment 2

[0061] This embodiment provides a kind of encapsulation Bi 2 S 3 The preparation method of the alginate microsphere of nanoparticle, comprises the following steps:

[0062] (1) Preparation of oil phase: weigh anhydrous CaCl 2 Dissolve in absolute ethanol, ultrasonically dissolve or stir to dissolve, then add to silicone oil containing 1.0wt% Span 80, stir and mix well, then magnetically stir in a 60°C water bath to completely evaporate the ethanol until the solution changes from turbid to clear , after cooling to room temperature, the oil phase can be obtained;

[0063] (2) Preparation of water phase: first prepare 1.5wt% sodium alginate aqueous solution, then add Na 2 S, make Na 2 When the S concentration is 0.1mol / L, the aqueous phase is obtained;

[0064] (3) Preparation of Bi 3+ and Ca 2+ Acidic receiving solution: Weigh a certain amount of BiCl 3 and CaCl 2 Dissolved in 10wt% dilute sulfuric acid to make Bi 3+ and Ca 2+ The final concentration of each is 0.1mol...

Embodiment 3

[0068] This embodiment provides a kind of encapsulation Bi 2 S 3 The preparation method of the alginate microsphere of nanoparticle, comprises the following steps:

[0069] (1) preparation oil phase: with embodiment 1;

[0070] (2) Prepare the water phase: first prepare 5.0wt% sodium alginate aqueous solution, then add thiourea, the final concentration of thiourea is 0.5mol / L, and stir to obtain the water phase;

[0071] (3) Preparation of Bi 3+ and Ca 2+ Acidic receiving solution: Weigh a certain amount of BiCl 3 and Ca(NO 3 ) 2 Dissolved in 20wt% dilute nitric acid to make Bi 3+ and Ca 2+ The final concentration of is 0.5mol / L and 3.0mol / L respectively, then add Tween20 and Oπ-10, make both final concentrations be 5.0wt / V%;

[0072] (4) Preparation of microspheres by microfluidic method: use a T-shaped microfluidic chip, set the flow rate of the oil phase to 6000 μL / h, and the flow rate of the water phase to 2000 μL / h to form droplets with uniform particle size, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com