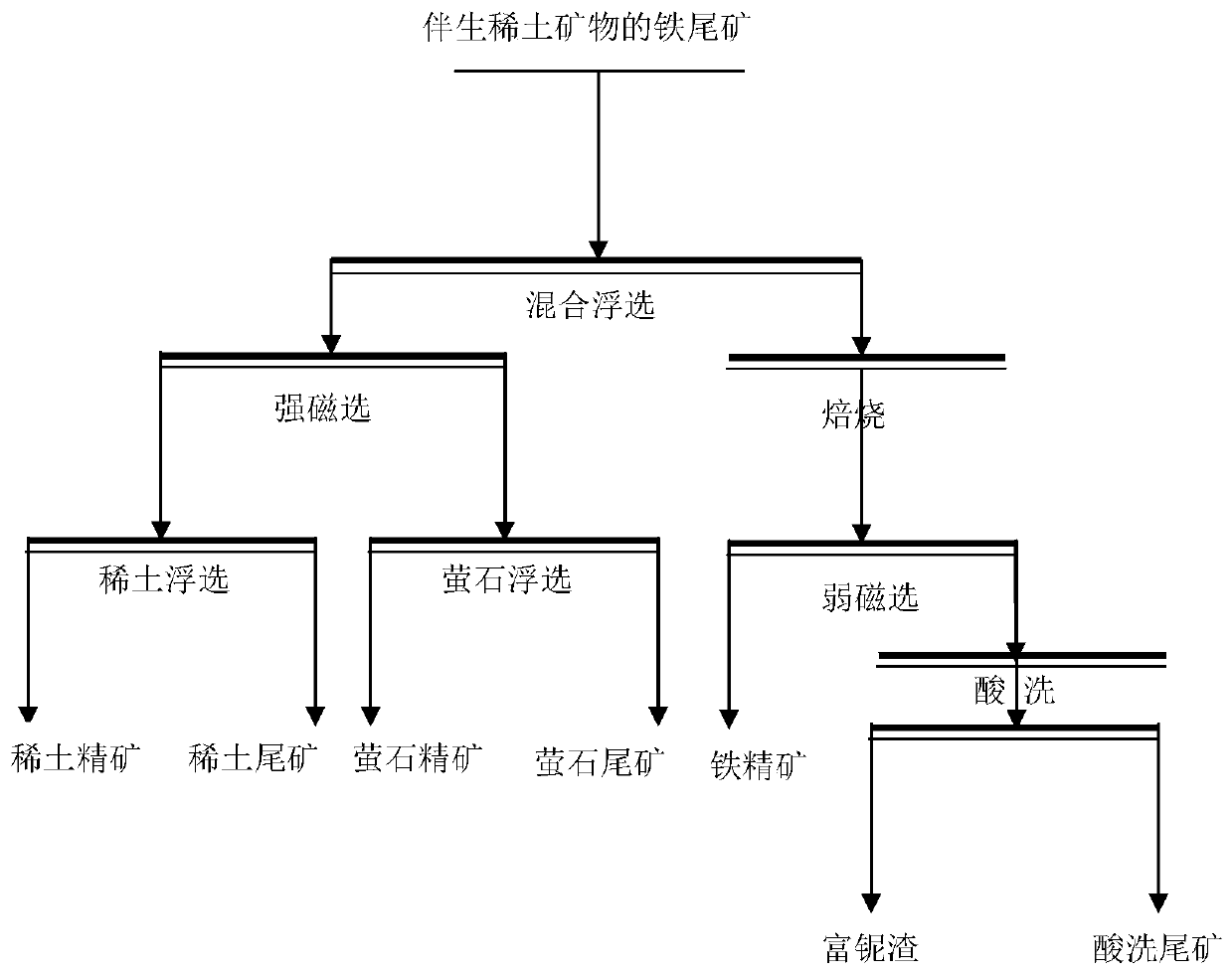

A multi-component recovery and beneficiation method of iron tailings with associated rare earth minerals

A technology for iron tailings and rare earths, applied in chemical instruments and methods, solid separation, wet separation, etc., to reduce the content of harmful impurities, increase the grade and recovery rate, and improve the comprehensive utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this example, the tailings in the Baiyun Obo tailings pond are used as raw materials, in which the grade of iron (TFe) is 15.62%, and the grade of fluorite (CaF 2 ) grade is 19.30%, rare earth (REO) grade is 6.87%. Utilize the method of the present invention to finally obtain the fluorite concentrate with a fluorite grade of 95.26% and a recovery rate of 82.23%; the rare earth concentrate with a rare earth grade of 66.54% and a recovery rate of 83.12%; the iron grade of 64.89% and a recovery rate of 87.65% % iron ore concentrate; Concretely comprises the following steps:

[0039] (1) Slurry the tailings in the Baiyun Obo tailings pond and perform mixed flotation operation, add water glass with inhibitor 0.50kg / t, sodium oleate with collector 0.35kg / t, adjuster 0.50kg / t t of sodium carbonate to obtain mixed flotation concentrates and mixed flotation tailings, respectively.

[0040] (2) The mixed flotation concentrate obtained in step (1) is fed into a strong magneti...

Embodiment 2

[0047] In this example, the tailings in the Baiyun Obo tailings pond are used as raw materials, in which the grade of iron (TFe) is 13.47%, and the grade of fluorite (CaF 2 ) grade is 22.45%, rare earth (REO) grade is 6.56%. Utilize the method of the present invention to finally obtain the fluorite concentrate with a fluorite grade of 96.46% and a recovery rate of 80.26%; the rare earth concentrate with a rare earth grade of 63.58% and a recovery rate of 87.26%; the iron grade of 63.69% and a recovery rate of 86.76% % iron ore concentrate; Concretely comprises the following steps:

[0048] (1) Slurry the tailings in the Baiyun Obo tailings pond and perform mixed flotation operation, add water glass with inhibitor 0.45kg / t, sodium oleate with collector 0.45kg / t, adjuster 0.40kg / t t of sodium carbonate to obtain mixed flotation concentrates and mixed flotation tailings, respectively.

[0049] (2) The mixed flotation concentrate obtained in step (1) is fed into a strong magneti...

Embodiment 3

[0056] In this example, the tailings in the Baiyun Obo tailings pond are used as raw materials, in which the grade of iron (TFe) is 15.62%, and the grade of fluorite (CaF 2 ) grade is 19.30%, rare earth (REO) grade is 6.87%. Utilize the method of the present invention to finally obtain the fluorite concentrate with a fluorite grade of 95.26% and a recovery rate of 82.23%; the rare earth concentrate with a rare earth grade of 66.54% and a recovery rate of 83.12%; the iron grade of 64.89% and a recovery rate of 87.65% % iron ore concentrate; Concretely comprises the following steps:

[0057] (1) Slurry the tailings in the Baiyun Obo tailings pond and perform mixed flotation operation, add inhibitor 0.50kg / t water glass, collector 0.35kg / t sodium oleate, adjuster 0.50kg / t carbonic acid Sodium, respectively to obtain mixed flotation concentrate and mixed flotation tailings.

[0058] (2) The mixed flotation concentrate obtained in step (1) is fed into a strong magnetic separator,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com