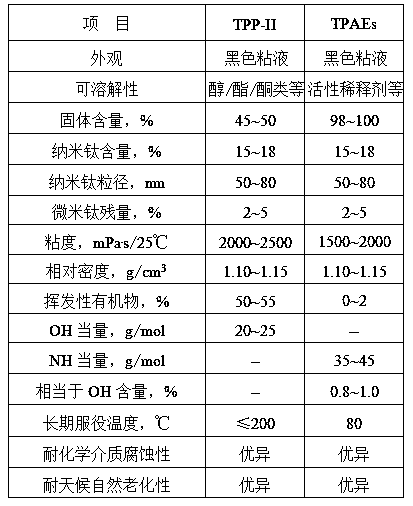

Preparation method of organic titanium polyaspartic acid ester and application thereof in ocean heavy anticorrosive coatings

A technology of aspartate and organic titanium, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problem of expensive titanium materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

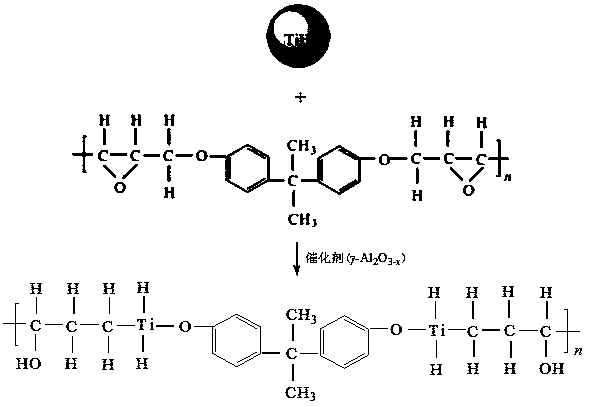

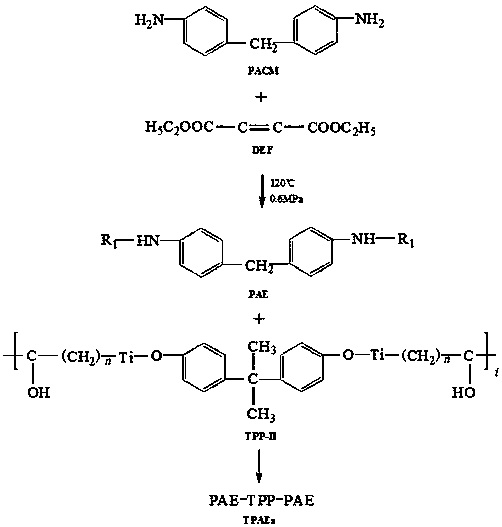

Method used

Image

Examples

Embodiment Construction

[0034] 1. Description of planetary ultrasonic assisted solid-liquid ball milling reactor:

[0035] Working principle: When it is necessary to apply ultrasonic waves, insert the plug of the ultrasonic generator into the socket of the energy converter, and at the same time turn on the switch on the ultrasonic generator, at this time the energy converter starts to work, and the ultrasonic waves can be input. Due to the strong penetrating ability of the ultrasonic wave, it can penetrate the stainless steel plate with a thickness of 2mm, and have physical and chemical effects on the materials in the ball mill tank.

[0036] Technical parameter setting of ultrasonic-assisted solid-liquid ball milling reactor:

[0037] (1) Planetary transmission mechanism: autobiography 18-168 r / min (turntable); revolution 70-670 r / min (ball mill tank).

[0038] (2) Ultrasonic frequency: 40KHz.

[0039](3) Ultrasonic power: 200W.

[0040] (4) Ultrasonic intensity: 1.13 W / cm 3 .

[0041] 2. Prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com