Immunosorbent for rheumatoid factors for blood perfusion and preparation method thereof

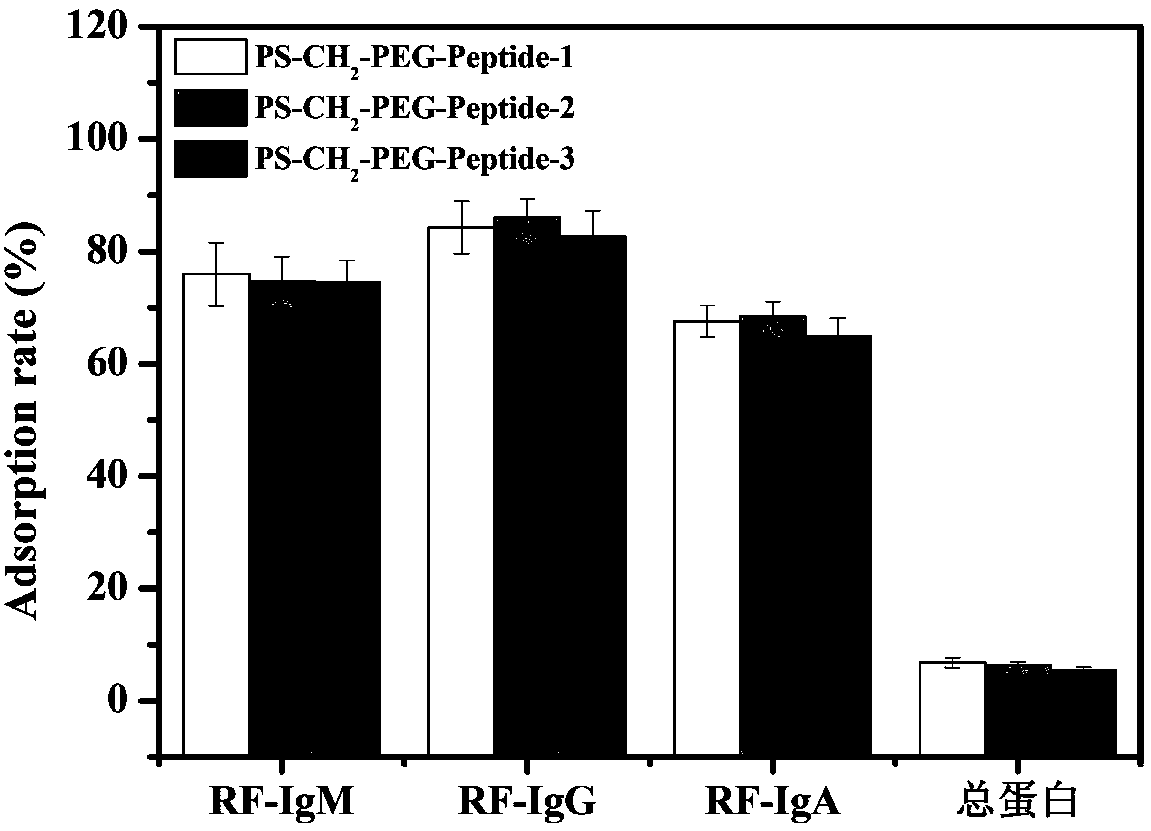

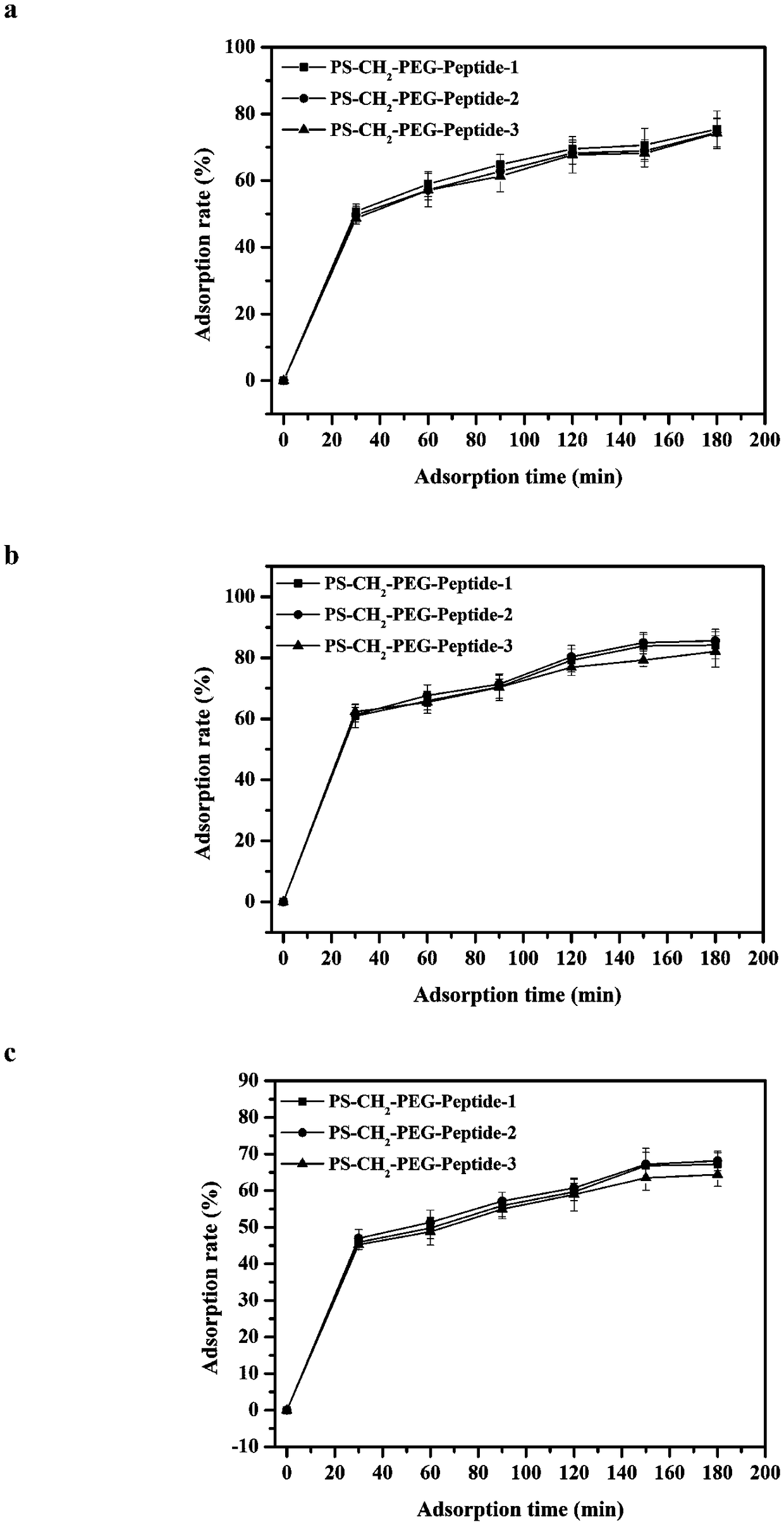

A technology of immunosorbent and rheumatoid factor, which is applied in the field of biomedicine, can solve the problems of poor specific adsorption and poor removal effect, and achieve the effects of improving adsorption performance, good biocompatibility, and avoiding non-specific adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

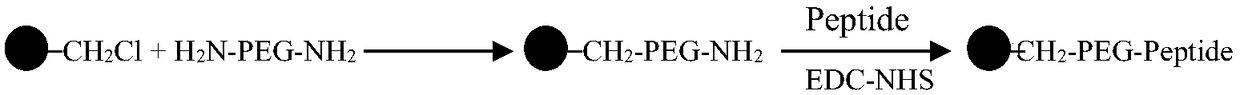

[0032] (1) Preparation of polystyrene-divinylbenzene carrier microspheres with chloromethylated macroporous structure;

[0033] (1.1) Preparation of polystyrene-divinylbenzene microspheres with macroporous structure

[0034] Add 70g of monomer styrene, 20g of crosslinking agent divinylbenzene; porogen (toluene 29.5g, kerosene 37g and octane 221.5g) and initiator benzoyl peroxide (BPO) 1.79g; into a 2000mL three-necked flask , stir to mix evenly, then add 456g, 2.9% polyvinyl alcohol aqueous solution, adjust the stirring speed at 120-160rpm / min, make the system disperse into uniform small oil droplets, raise the temperature to 52°C, and set the temperature at 5°C / 10min Raise the temperature to 70°C, keep it at this temperature for 8 hours after setting the shape, then slowly raise the temperature to 92°C at a rate of 1°C / 5min, and react for 12 hours. After the reaction system is filtered and washed, polystyrene with macroporous structure is obtained. - divinylbenzene microsphe...

Embodiment 2

[0042] (1) Preparation of polystyrene-divinylbenzene carrier microspheres with chloromethylated macroporous structure

[0043] (1.1) Preparation of polystyrene-divinylbenzene microspheres with macroporous structure

[0044] With monomer styrene 83.3g, crosslinking agent divinylbenzene 16.7g; porogen (toluene 29.6g, kerosene 32.0g and octane 138.4g) and initiator benzoyl peroxide (BPO) 7g; Add to 2000mL In the three-necked flask, stir to mix evenly, then add 840g, 1.4% polyvinyl alcohol aqueous solution, adjust the stirring speed at 120-160rpm / min, make the system disperse into uniform small oil droplets, heat up to 52°C, and / 10min to raise the temperature to 75°C, keep the temperature at this temperature for 6 hours, then slowly raise the temperature to 94°C at a rate of 2°C / 5min, and react for 9.5 hours. After the reaction system is filtered and washed, the macroporous structure is obtained. Polystyrene-divinylbenzene microspheres. The particle size is 400-600μm, and the s...

Embodiment 3

[0051] (1) Preparation of polystyrene-divinylbenzene carrier microspheres with chloromethylated macroporous structure

[0052] (1.1) Preparation of polystyrene-divinylbenzene microspheres with macroporous structure

[0053] Synthesis of carrier microspheres: monomer styrene 120g, crosslinking agent divinylbenzene 20g; porogen toluene 41.8g, kerosene 52.3g and octane 365.9g and initiator benzoyl peroxide (BPO) 9g; add Put it into a 2000mL three-neck flask, stir to mix evenly, then add 600g, 2.5% polyvinyl alcohol aqueous solution, adjust the stirring speed at 120-160rpm / min, make the system disperse into uniform small oil droplets, heat up to 58 °C, and 10°C / 10min to raise the temperature to 80°C, keep at this temperature for 4 hours after setting, then slowly raise the temperature to 95°C at a speed of 2°C / 5min, react for 8 hours, the reaction system is filtered, washed and treated to obtain a macroporous structure polystyrene-divinylbenzene microspheres. The particle size i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com