Preparation method for modified starch based polyethylene plastic

A polyethylene plastic and starch-based technology, applied in the field of preparation of modified starch-based polyethylene plastics, can solve the problems of inability to meet market requirements of materials, poor degradability, poor flame retardancy, etc., achieve excellent biodegradability, improve water resistance, etc. The effect of slowing down heat and mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

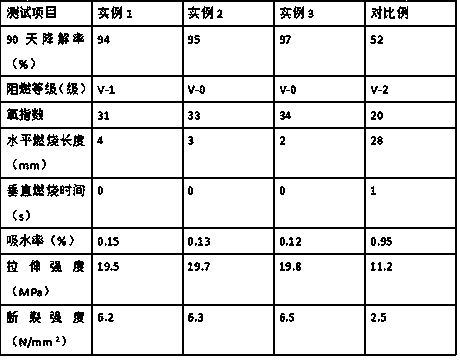

Examples

example 1

[0023]Put potato starch and deionized water in a beaker at a mass ratio of 1:7, mix and stir for 16 minutes at a temperature of 80°C to obtain a starch paste, cool naturally to 24°C, and adjust with hydrochloric acid with a mass fraction of 11%. The pH value of the starch paste reaches 5 to obtain a starch mixture, then add isoamylase with 1% of the mass of the starch mixture to the starch mixture, stir and enzymolyze at a temperature of 32°C for 47 minutes, filter to remove the filter residue, and obtain a filtrate It is the starch reaction solution; then the starch reaction solution, 3% sodium hydroxide solution, epichlorohydrin and succinic anhydride are mixed according to the mass ratio of 5:1:2:1, and the temperature is 35 ° C Stir and react for 21 minutes to obtain a mixed solution, continue to put the mixed solution into a suction filter and filter for 3 times, remove the filtrate to obtain a solid, air-dry naturally, grind and discharge, and obtain modified starch granu...

example 2

[0025] Put potato starch and deionized water in a beaker at a mass ratio of 1:7, mix and stir for 17 minutes at a temperature of 82°C to obtain a starch paste, cool naturally to 28°C, and adjust with hydrochloric acid with a mass fraction of 11%. The pH value of the starch paste reaches 5 to obtain a starch mixture, then add isoamylase with 1% of the mass of the starch mixture to the starch mixture, stir and enzymolyze at a temperature of 34°C for 49 minutes, filter to remove the filter residue, and obtain a filtrate It is the starch reaction solution; then mix the starch reaction solution, 3% sodium hydroxide solution, epichlorohydrin and succinic anhydride in a mass ratio of 5:1:2:1, and mix at a temperature of 37°C Stir and react for 22 minutes to obtain a mixed solution, continue to put the mixed solution into a suction filter and filter 4 times, remove the filtrate to obtain a solid, air-dry naturally, grind and discharge, and obtain modified starch granules; weigh 6 mL of...

example 3

[0027] Put potato starch and deionized water in a beaker at a mass ratio of 1:7, mix and stir for 18 minutes at a temperature of 85°C to obtain a starch paste, cool naturally to 32°C, and adjust with hydrochloric acid with a mass fraction of 11%. The pH value of the starch paste reaches 6 to obtain a starch mixture, then add isoamylase with 1% of the mass of the starch mixture to the starch mixture, stir and enzymolyze at a temperature of 35°C for 52 minutes, filter to remove the filter residue, and obtain a filtrate It is the starch reaction solution; then the starch reaction solution, 3% sodium hydroxide solution, epichlorohydrin and succinic anhydride are mixed according to the mass ratio of 5:1:2:1, and the temperature is 40°C Stir and react for 24 minutes to obtain a mixed solution, continue to put the mixed solution into a suction filter and filter it for 5 times, remove the filtrate to obtain a solid, air-dry naturally, grind and discharge, and obtain modified starch gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com