An anthraquinone dye dispersant, ink and electrowetting display

A technology of dye dispersants and anthraquinones, which is applied in the direction of anthracene dyes, inks, organic dyes, etc., can solve the problems of easy degradation of organic dyes and achieve the effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

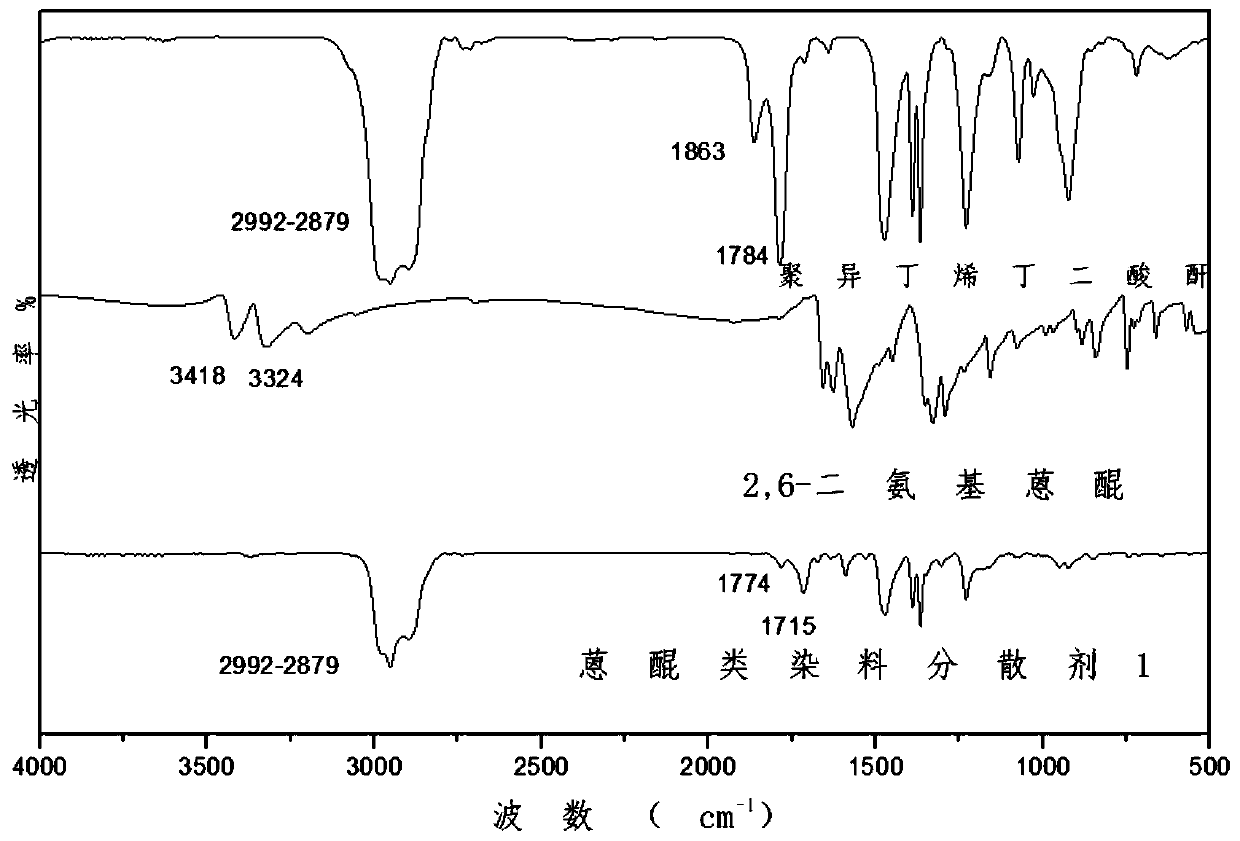

[0036] Anthraquinone dye dispersant 1 was synthesized according to the synthetic reaction formula shown below:

[0037]

[0038] The specific synthesis process is: take 3.7g of 2,6-diaminoanthraquinone (0.015moL, 238.25g / moL, mass fraction is 97%) and slowly add 39g of PIB- SA (polyisobutylene succinic anhydride, English name: polyisobutylene-g-succinic anhydride, n=25~26, average molar mass M W =1300g / mol, 0.03moL, 1300g / moL) was dissolved in 100mL tetrahydrofuran (THF) system, heated to 80°C for 20h, TCL (developing solvent: ethyl acetate: petroleum ether = 1:1) showed that most of the raw materials After the reaction, N 2 , the temperature was raised to 150° C., and the reaction was carried out for 10 h. After the reaction was completed, the solvent was distilled off under reduced pressure to obtain the product. The product is purified by column chromatography, and the eluent is ethyl acetate / petroleum ether to obtain anthraquinone dye dispersant 1, whose structural fo...

Embodiment 2

[0046] Anthraquinone dye dispersant 2 was synthesized according to the synthetic reaction formula shown below:

[0047]

[0048] First, compound 1 was synthesized: 2.4g of 1-chloroanthraquinone (0.01moL, 242.66g / moL) was dissolved in 50mL of ethylenediamine, stirred at 70°C for 2h, cooled to room temperature, and adjusted to pH 1 by adding hydrochloric acid. NaOH was added to the aqueous phase to adjust the pH to 9, filtered three times, and the solid was vacuum-dried to obtain compound 1.

[0049] Synthesis of anthraquinone dye dispersant 2: Weigh 0.68g of the above compound 1 (3mmoL, 226g / moL) and dissolve it in 5mL of N,N-dimethylformamide (DMF), add it to 10mL of 3.9g PIB- SA (polyisobutylene succinic anhydride, English name: polyisobutylene-g-succinic anhydride, n=25~26, average molar mass M W =1300g / mol, 3mmoL, 1300g / moL) system, reaction temperature 80 ℃, reaction 10h, TCL (developing agent is ethyl acetate), detection compound 1 reacts substantially completely, pas...

Embodiment 3

[0057] Anthraquinone dye dispersant 3 was synthesized according to the synthetic reaction formula shown below:

[0058]

[0059] The specific synthesis process is as follows: Take 0.58g of 2-aminoanthraquinone (0.0025moL, 223.2g / moL, mass fraction is 97%) and slowly add 3.25g of PIB-SA ( Polyisobutylene succinic anhydride, n=25~26, average molar mass M W =1300g / mol, 0.0025moL, 1300g / moL) dissolved in 100mL tetrahydrofuran (THF) system, heated to 80°C for 20h, TCL (developing solvent: ethyl acetate: petroleum ether = 1:3) showed that most of the raw materials After the reaction, N 2 , the temperature was raised to 150° C., and the reaction was carried out for 10 h. After the reaction was completed, the solvent was distilled off under reduced pressure to obtain the product. The product is purified by column chromatography, and the eluent is ethyl acetate / petroleum ether to obtain anthraquinone dye dispersant 3, whose structural formula is: n=25-26, the yield was 34.2%.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com