Pure carbon nanodots, preparation method thereof and LED light source

An LED light source, nano-dot technology, applied in nano-optics, nano-technology, nano-technology, etc., can solve the problems of quenching, non-uniform size of carbon nano-dots, etc., achieve low risk, good experimental repeatability, high luminous intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a preparation method of pure carbon nano dots, a pure carbon nano dot and an LED light source.

[0033] In a first aspect, the present invention provides a method for preparing pure carbon nano-dots, comprising the steps of: adding inorganic salts, polyhydroxy compounds and amino compounds to deionized water, dissolving, and heating in vacuum to obtain pure carbon nano-dots; The mass ratio of the inorganic salt polyol to the amino compound is 0.1-2:0.1-5:1.

[0034] In some specific embodiments, the preparation method includes the steps of: adding inorganic salts, polyhydroxy compounds and amino compounds into deionized water, after fully dissolving, drying, and then heating in vacuum to obtain pure carbon nano-dots.

[0035] In some specific embodiments, the mass ratio of the inorganic salt, polyol and amino compound is 0.5-1.5:0.5-3:1, more preferably 0.5-1.5:0.5:1.

[0036] In some specific embodiments, the inorganic salt is selected from one ...

Embodiment 1

[0046] Dissolve 0.5g of anhydrous calcium chloride powder, 0.5g of citric acid and 1g of urea in deionized water. After being fully dissolved, dry it under normal pressure, and then heat it at 250°C for one hour in a vacuum state to obtain carbon nano Click Product D1.

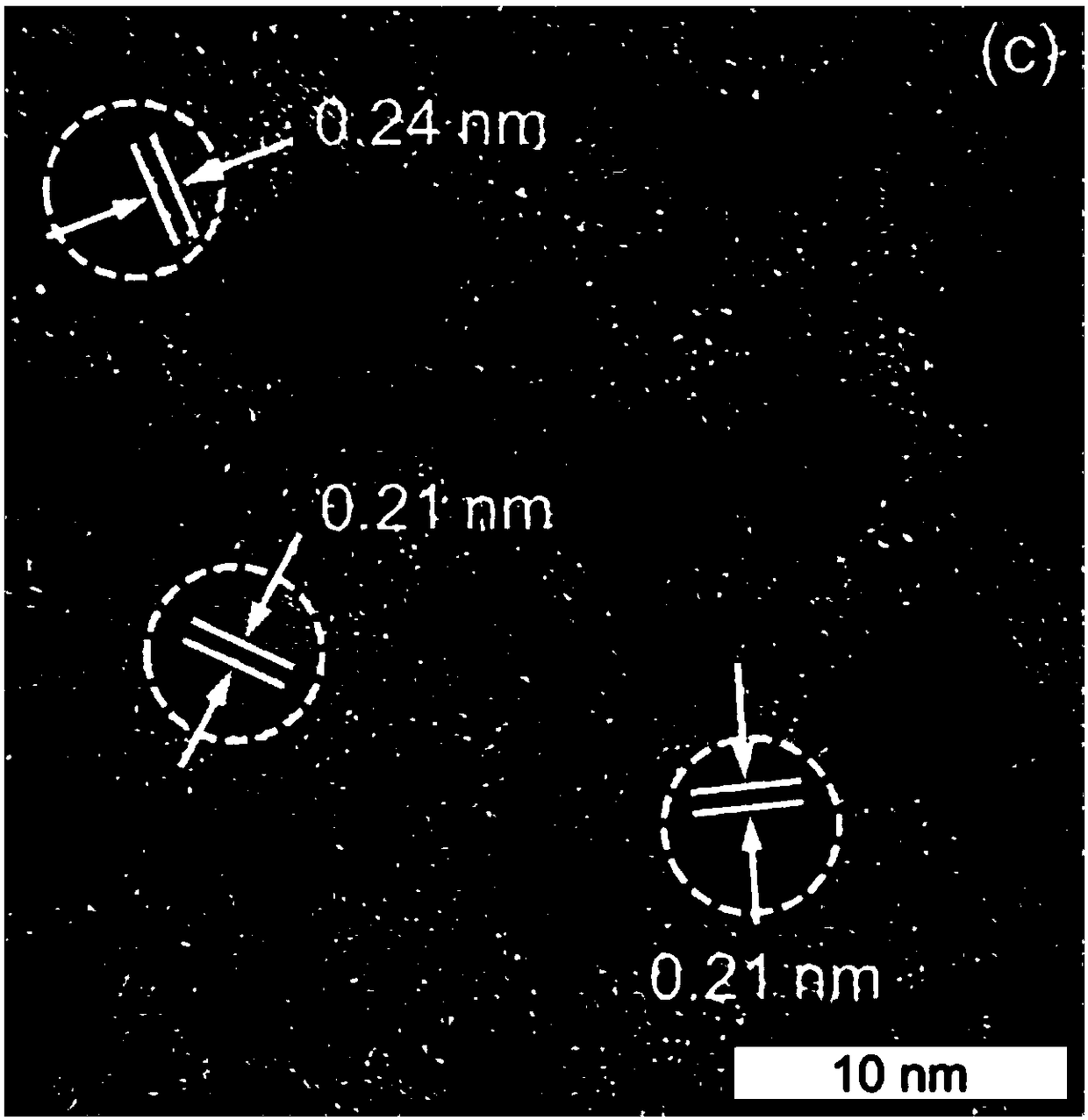

[0047] Such as Figure 1A It is a room light photograph of the carbon nano-dot product of Example 1 of the present invention, Figure 1B It is a fluorescent photo of the carbon nanodot product of Example 1 of the present invention, Figure 1C It is a TEM transmission photo of the carbon nanodot product of Example 1 of the present invention. from Figure 1A with Figure 1B It can be seen that the prepared carbon nanodot product D1 presents a puffed spherical shape and has bright yellow-green fluorescence. from Figure 1C It can be calculated that the prepared carbon nano-dots are spherical nanoparticles with a particle diameter of about 4 nm.

Embodiment 2

[0049] Dissolve 0.8g of anhydrous calcium chloride powder, 0.5g of citric acid and 1g of urea in deionized water. After being fully dissolved, dry it under normal pressure, and then heat it at 250°C for one hour in a vacuum state to obtain carbon nano point product, and dissolved it in deionized water to obtain carbon nano-dot product D2.

[0050] Figure 2A It is the ultraviolet-visible absorption spectrum when the carbon nanodot product D2 of Example 2 of the present invention is dissolved in deionized water, Figure 2B It is the fluorescence emission spectrum when the carbon nanodot product D2 of Example 2 of the present invention is dissolved in deionized water. from Figure 2A It can be seen that the ultraviolet absorption peaks of the prepared carbon nanodots D2 are at 330 and 406 nm. from Figure 2B It can be seen that the fluorescence emission peak of the carbon nanodot aqueous solution is at 520nm, which has green fluorescence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com