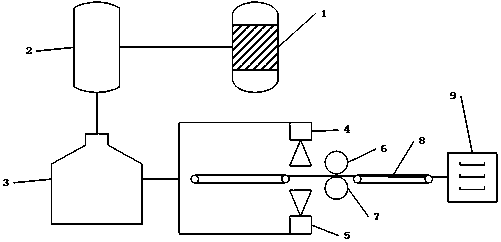

Corrugated paper sizing device

A corrugated paper and sizing roller technology, applied in the field of papermaking, can solve the problems of reducing the quality of articles, burning, economic losses, etc., and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of flame-retardant corrugated paper is as follows: it is composed of a flame-retardant layer, a corrugated paper core, a filling layer and a flame-retardant layer in sequence, specifically, the corrugated paper core is composed of wood pulp, starch and sugarcane stem fiber in a weight ratio of 10: It is made by mixing 4:2:1; after crushing, purification, flotation and refining, the resulting slurry is made to obtain a corrugated paper core; two corrugated paper cores and the fire extinguishing materials placed in them are subjected to high pressure to form a filling layer; After the corrugated paper core and filling layer are pressed together, glue is applied on the surface to form corrugated paper.

[0020] The surface sizing method is:

Embodiment 1

[0022] (1) First, mix 5 parts of melamine, 10 parts of urea, and 5 parts of tricresyl phosphate in parts by weight, and add them to the reaction kettle, and then add 1 part of magnesium hydroxide, 6 parts of calcium borate, 10 parts of Calcium carbonate, heated to 180°C, holding time 1.5 hours;

[0023] (2) Add the above mixture into the hydrothermal tank, and successively add 15 parts by weight of hydroxypropyl distarch phosphate, 11 parts by weight of sodium perborate, a temperature of 85°C, and a reaction time of 2 hours; then add 45 parts by weight of epoxy - Polyurethane glue is stirred to form glue

[0024] (3) After adding water-resistant agent to the glue, stir evenly, then transport the mixed glue to the liquid storage tank, and the glue in the liquid storage tank is directly transported to the sizing machine for surface sizing, and then dried in an oven.

Embodiment 2

[0026] (1) First, mix 10 parts of melamine, 12 parts of urea, and 3 parts of tricresyl phosphate in parts by weight, and add them to the reaction kettle, and then add 3 parts of magnesium hydroxide, 2 parts of calcium borate, and 3 parts of Calcium carbonate, heated to 160°C, holding time 1 hour;

[0027] (2) Add the above-mentioned mixture into a hydrothermal tank, and successively add 22 parts by weight of hydroxypropyl distarch phosphate, 6 parts by weight of sodium perborate, a temperature of 65°C, and a reaction time of 3 hours; then add 30 parts by weight of epoxy - Polyurethane glue is stirred to form glue

[0028] (3) After adding water-resistant agent to the glue, stir evenly, then transport the mixed glue to the liquid storage tank, and the glue in the liquid storage tank is directly transported to the sizing machine for surface sizing, and then dried in an oven.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com