A kind of finishing process method of imitation incense branch wood

A process method, the technology of incense branch wood, applied in the direction of decorative arts, wood processing equipment, special decorative structures, etc., can solve the problems of high cost, poor finishing effect, cumbersome operation, etc., and achieve the effect of low equipment requirements and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

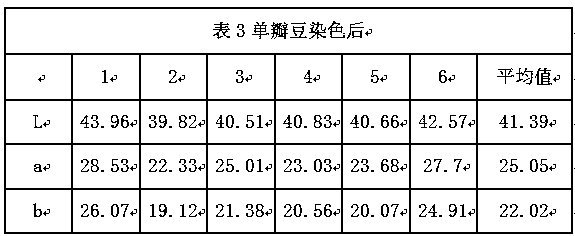

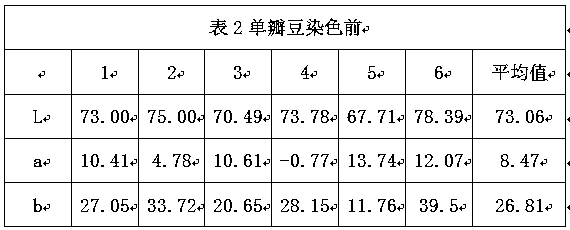

[0042] A method of dyeing and finishing imitation incense branch wood, using 2% potassium permanganate as the dyeing agent, drawing patterns on the surface of the pretreated veneer with a glass rod, drying it in the room for ten minutes, putting it in an oven for 20 minutes at 50°C Sanding; then use sodium hydroxide as the treatment solution, brush 1% sodium hydroxide on the single bean, dry in an oven at 50°C for 20 minutes and then sand; after that, apply distilled water unevenly: active red: active yellow= 100: 2: 1 and distilled water: reactive red: reactive yellow = 100: 1.5: 1 dyeing agent, sanded after drying; then circle coated with distilled water: talcum powder: iron red pigment: iron black pigment: iron yellow pigment: =100 :2:0.1:1:1 coloring agent, dry it indoors for 10 minutes, put it in an oven at 50°C, dry it for 20 minutes, and then sand it; then apply distilled water in circles: sandalwood powder: fluorescent powder = 10:1:0.2 Dried for 10 minutes indoors, pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com