Three-dimensional porous vanadium pentoxide anode material, and simple preparation method and application of anode material

A technology of vanadium pentoxide and positive electrode materials, applied in vanadium oxide, nanotechnology for materials and surface science, battery electrodes, etc., can solve the problems of limiting the application and promotion of vanadium pentoxide positive electrode materials, poor cycle stability, etc. , to achieve the effects of improving cycle performance and rate performance, preventing agglomeration, and buffering volume changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

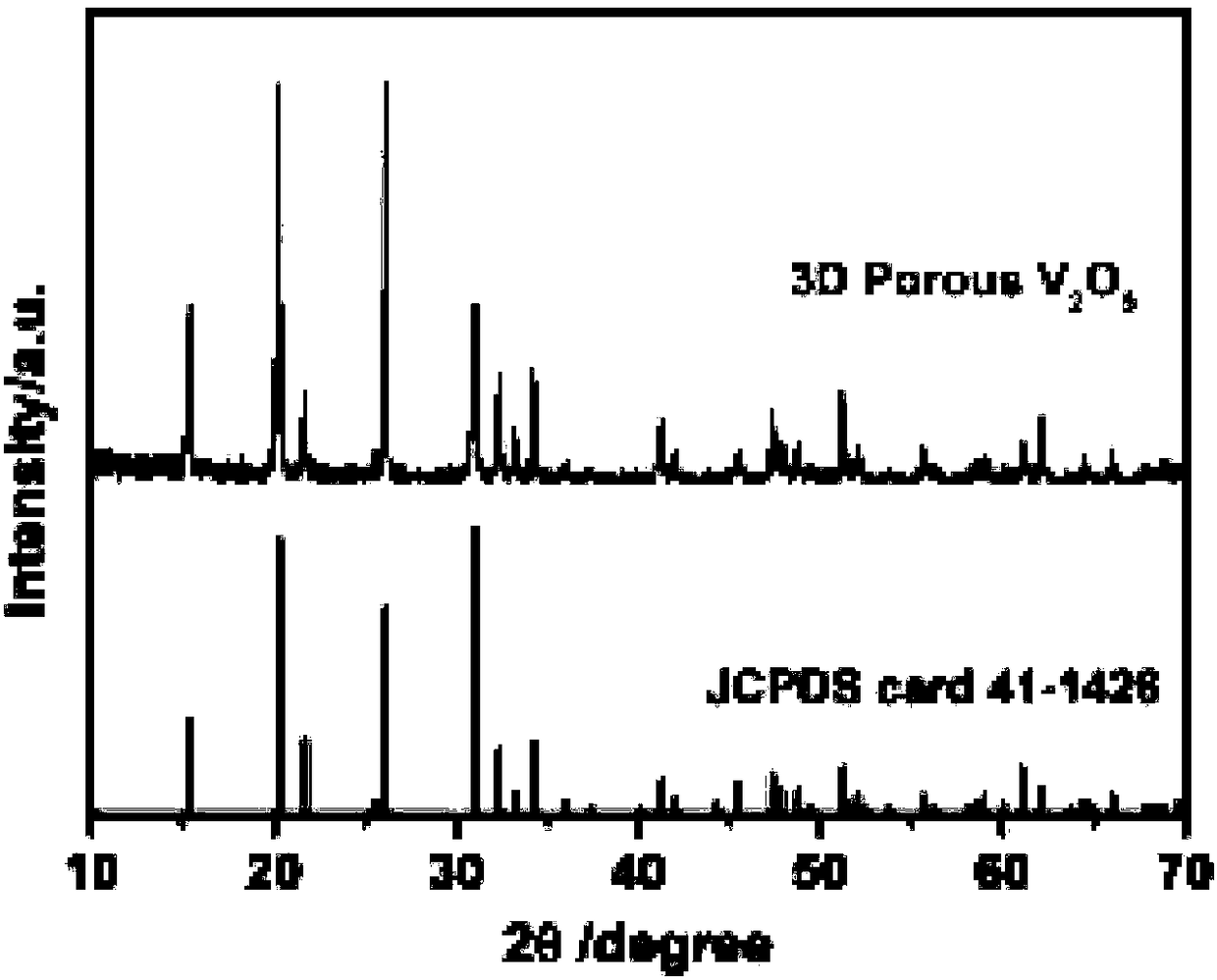

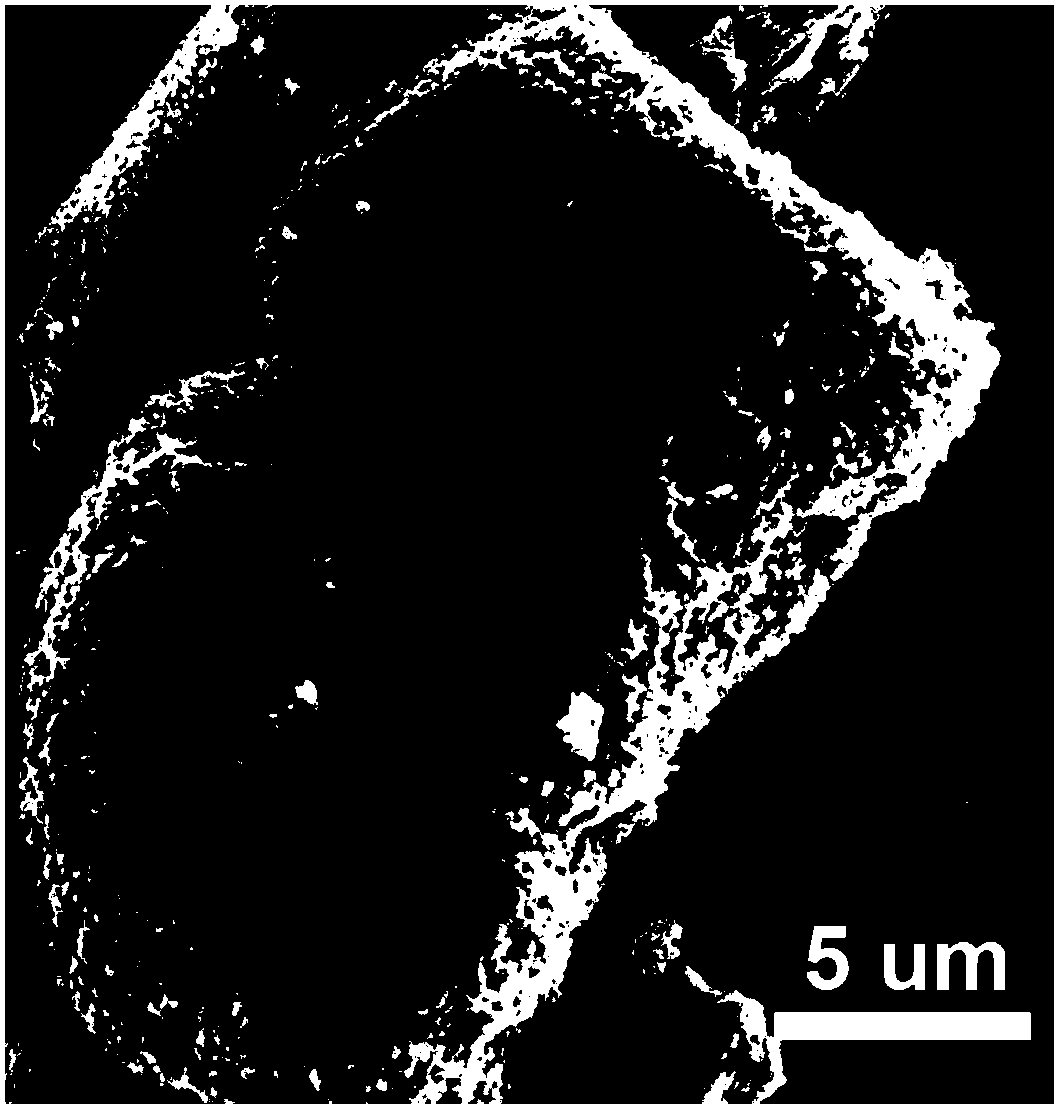

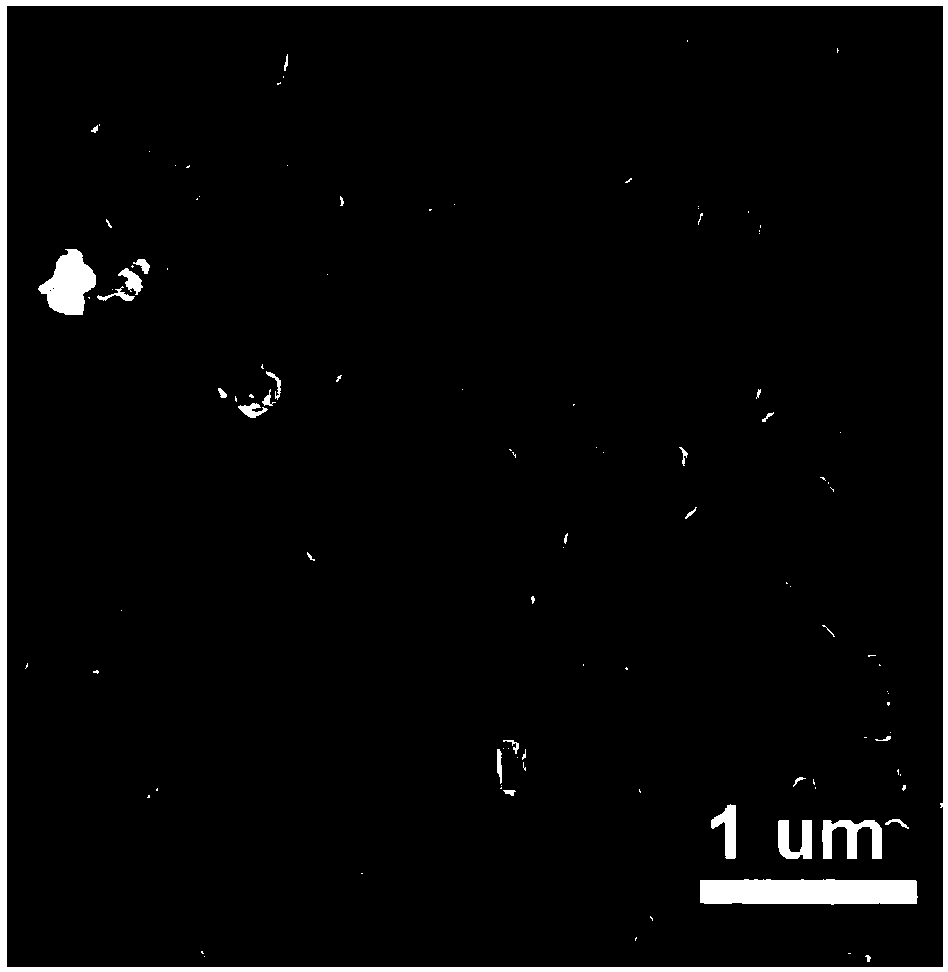

[0033] Accurately weigh 300mg of vanadium pentoxide and 830mg of oxalic acid dihydrate, add them into 40mL of deionized water, stir magnetically at 80°C for 5 hours at a speed of 500r / min, then put them in a drying oven and dry at 80°C for 12 hours get the precursor. The precursor was ground in a mortar for 0.5 hour, and then the ground precursor was sintered in an air atmosphere at 500° C. for 5 hours to obtain a three-dimensional porous vanadium pentoxide cathode material.

[0034]Aiming at the problem that the existing nanostructured vanadium pentoxide positive electrode material is prone to agglomeration, which leads to its relatively poor rate performance and cycle performance, and curbs the application of the nanostructured vanadium pentoxide positive electrode material in lithium-ion batteries, the application The inventor, through a large number of experimental studies, prepared a gel precursor by using a vanadium source and a specific type of organic acid as a raw mat...

Embodiment 2

[0037] Accurately weigh 234 mg (2 mmol) of ammonium metavanadate and 2521 mg (20 mmol) of oxalic acid dihydrate, add them to 20 mL of deionized water, stir magnetically at 50 °C for 10 hours at a speed of 200 r / min, and then put them in a drying oven. Dry at 60°C for 12 hours to obtain the precursor. The precursor was ground in a mortar for 3 hours, and then the ground precursor was sintered in an air atmosphere at 300°C for 5 hours to obtain a three-dimensional porous vanadium pentoxide positive electrode material. The three-dimensional porous vanadium pentoxide positive electrode obtained in this example The structure and performance of the material are relatively close to that of Example 1.

Embodiment 3

[0039] Accurately weigh 234mg (2mmol) ammonium metavanadate, 182mg (1mmol) vanadium pentoxide, 1261mg (10mmol) oxalic acid dihydrate, 1181mg (10mmol) succinic acid, add to 20mL deionized water, and stir magnetically at 90°C 5 hours at a rotation speed of 1000r / min, then put into a drying oven, and dry at 90°C for 6 hours to obtain a precursor. The precursor was ground in a mortar for 3 hours, and then the ground precursor was sintered in an air atmosphere at 600°C for 5 hours to obtain a three-dimensional porous vanadium pentoxide positive electrode material. The three-dimensional porous vanadium pentoxide positive electrode obtained in this example The structure and performance of the material are relatively close to that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com