Production line and technology for preparing aluminophosphate cementing material from white clay

A cementing material and aluminophosphate technology, which is applied in the field of waste recycling, can solve the problems such as the inability to produce special aluminophosphate cementitious materials from white mud, and achieve good economic benefits, control pollution, and alleviate shortages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

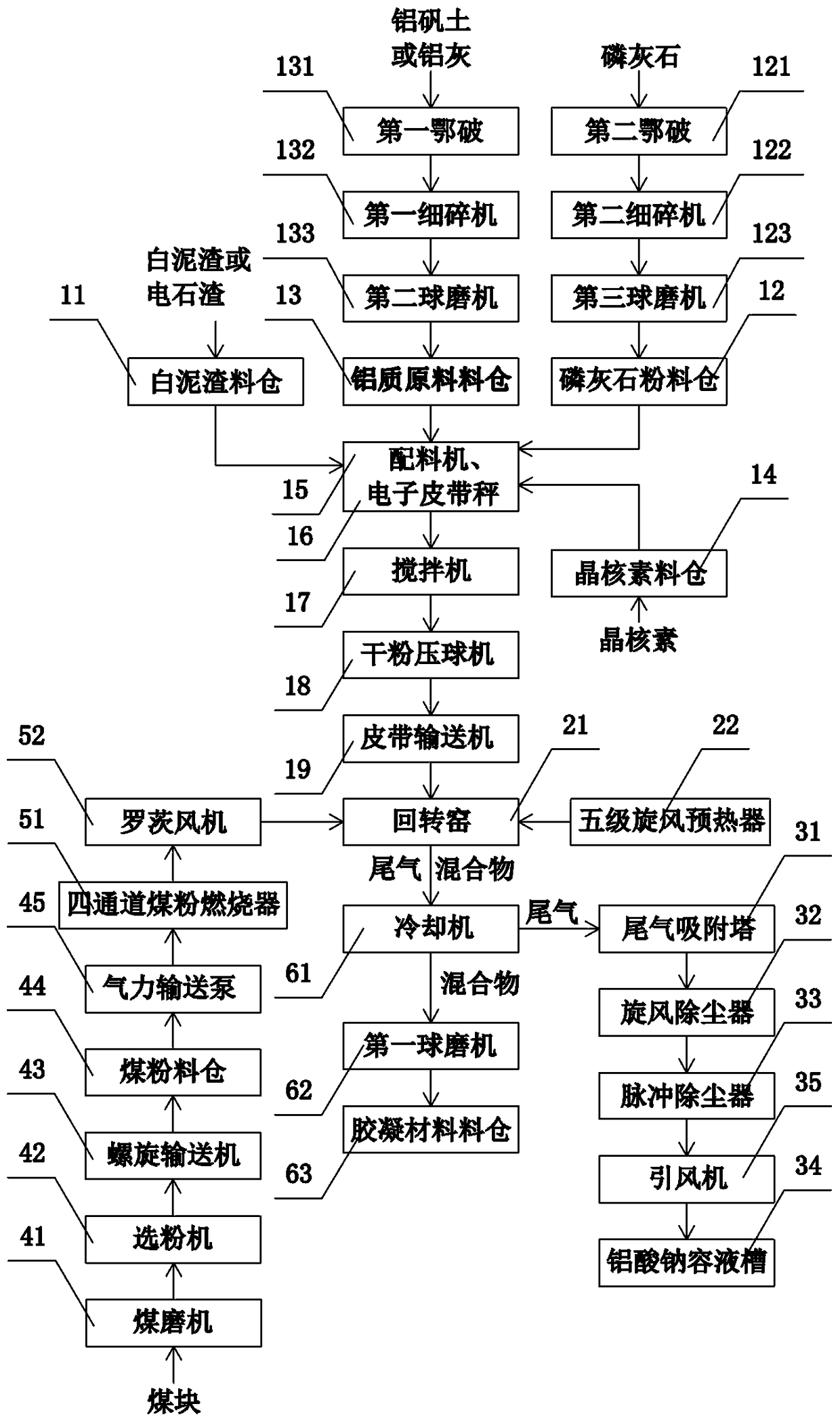

[0036] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

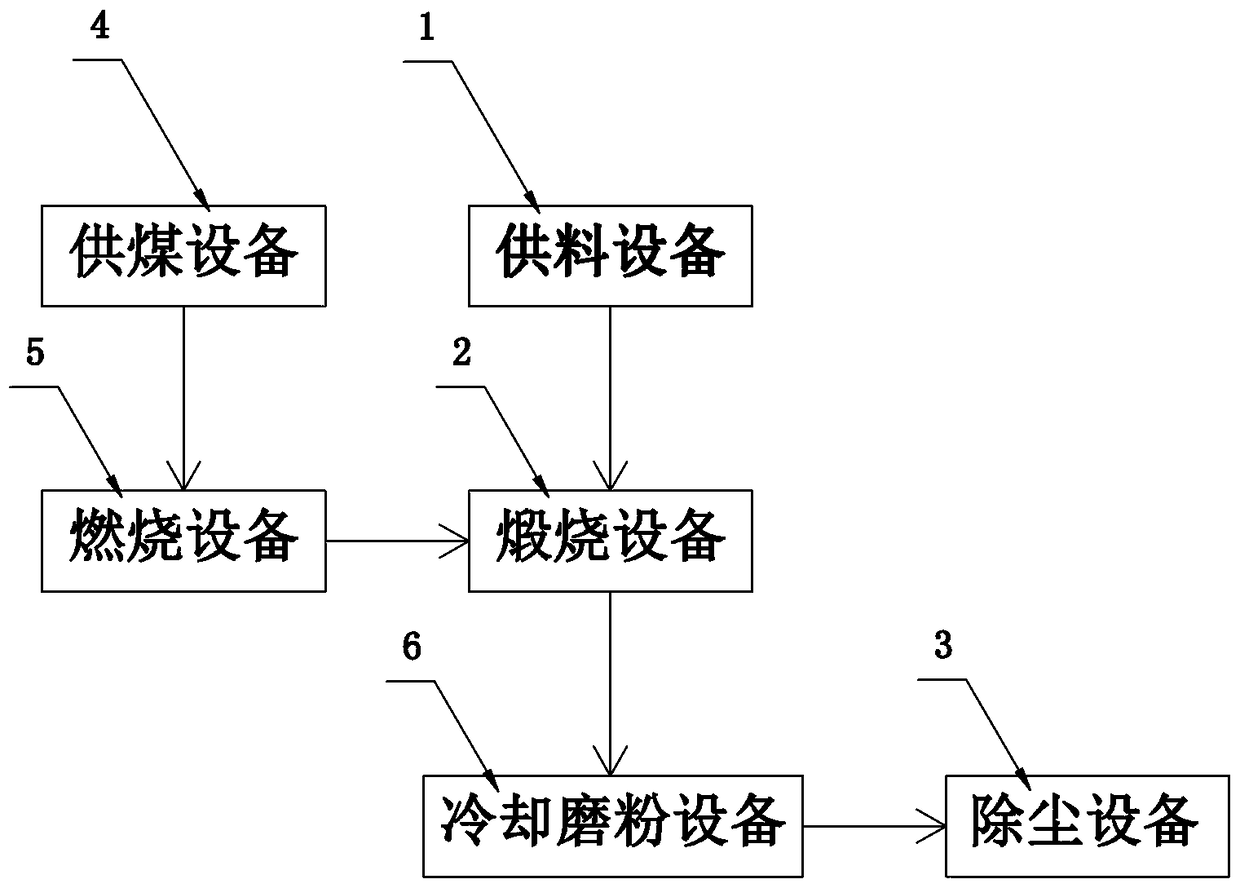

[0037] refer to figure 1 and figure 2 . A production line for preparing aluminophosphate cementitious materials from lime mud, including feeding equipment 1, calcining equipment 2, dust removal equipment 3, coal supply equipment 4, combustion equipment 5, and cooling and milling equipment 6. in,

[0038] The feeding equipment 1 includes a white mud slag silo 11 for accommodating white mud slag / calcium carbide slag, an apatite powder silo 12 for accommodating apatite powder, and an aluminum material silo for accommodating aluminum raw materials. Raw material bin 13, crystal nuclide bin 14 for accommodating crystal nuclide, batching machine 15, electronic belt scale 16, used for mixing white mud slag / carbide slag, apatite powder, aluminum raw material, crystal The mixer 17 of nuclide, the dry powder briquetting machine 18 that connects mixer 17 outlets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com