High-safety steel wall connecting piece

A high-security, wall-connecting technology, which is applied to the accessories of scaffolding, building structure supports, coatings, etc., can solve problems such as hidden safety hazards and large force on connection points, and achieve improved safety, firm connection, and improved The effect of connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

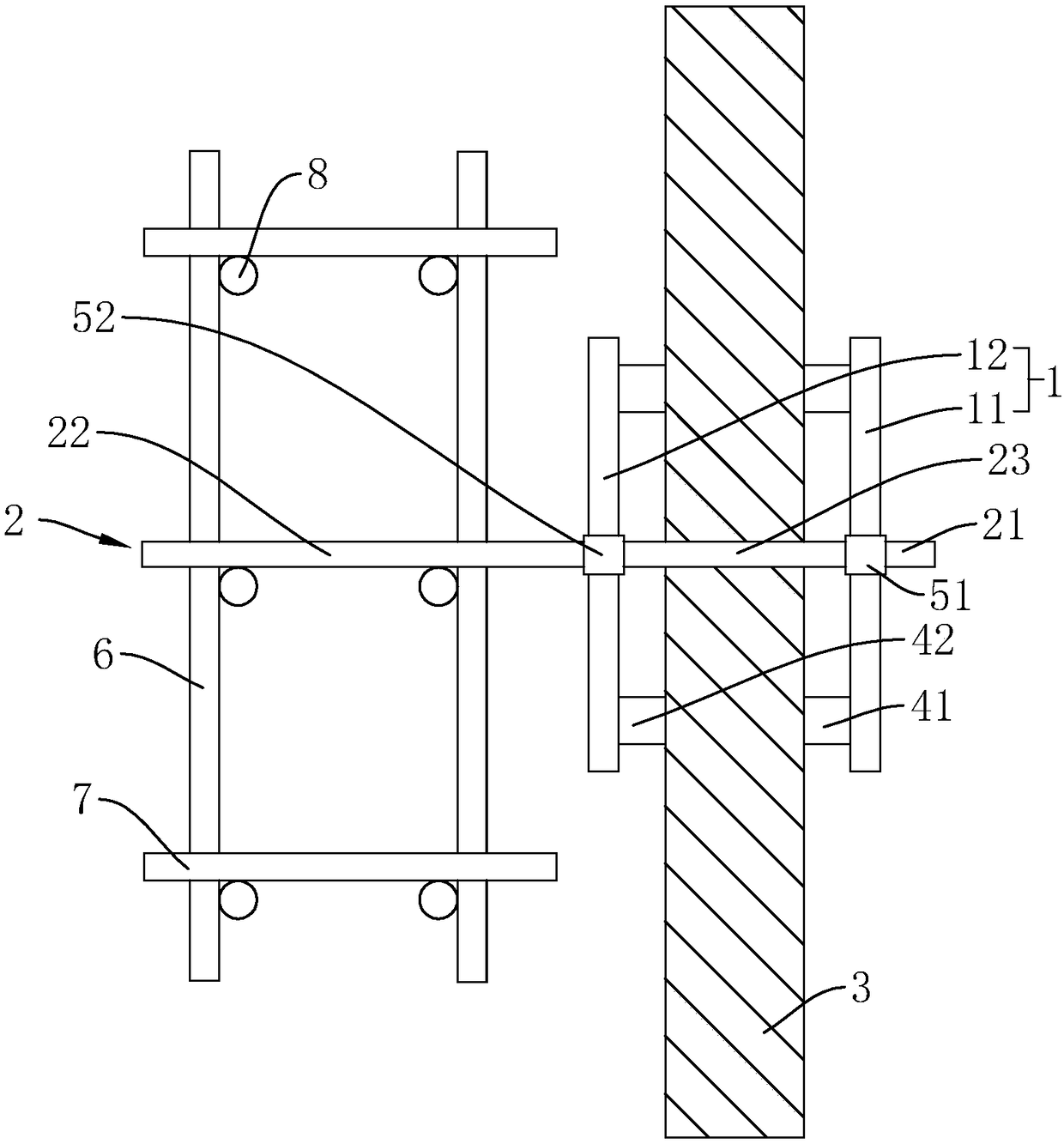

[0035] see figure 1 , a wall connecting piece, including a limiting steel pipe 1 and a positioning steel pipe 2 fixed on the limiting steel pipe 1 . The wall connecting piece is fixed on the wall body 3 provided with positioning holes, the positioning steel pipe 2 is pierced in the positioning hole, the limiting steel pipe 1 is connected with the positioning steel pipe 2 and clamped on both sides of the wall body 3 to complete the wall connecting piece of the lock.

[0036]The limit steel pipe 1 includes a first limit tube 11 positioned inside the wall body 3 and a second limit tube 12 positioned outside the wall body 3. The lengths of the first limit tube 11 and the second limit tube 12 are consistent and mutually Parallel and arranged at the same height relative to the wall body 3 . Both the first limiting tube 11 and the second limiting tube 12 are arranged along the length direction of the wall body 3 . Between both ends of the first limiting tube 11 and the inner side ...

Embodiment 2a

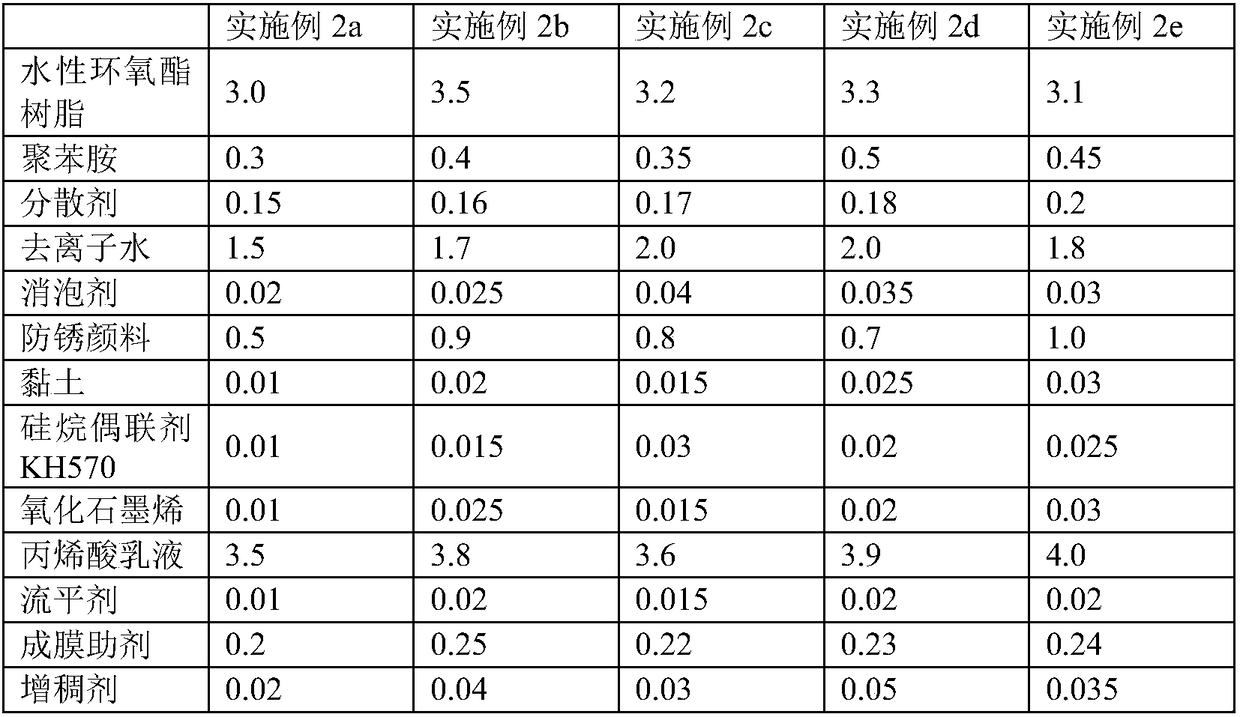

[0044] In embodiment 1, self-made waterborne acrylic acid modified epoxy ester primer is made by following preparation method:

[0045] Step1, add 3kg water-based epoxy ester resin to the batching tank, add 0.3kg polyaniline, 0.15kg dispersant, 1.5kg deionized water, 0.02kg defoamer, 0.5kg anti-rust pigment, 0.01kg clay, 0.01 kg silane coupling agent KH570, 0.01kg graphene oxide, grind evenly by a three-roller machine, remove the filter residue through a 500-mesh sieve, and obtain a pigment slurry;

[0046] Step2, add the pigment slurry prepared in Step1, 0.01kg leveling agent and 0.2kg film-forming aid to 3.5kg of acrylic emulsion while stirring, and add 0.02kg of thickener to adjust the viscosity to obtain the water-based acrylic modified ring Oxygen ester primer.

[0047] in:

[0048] The dispersant was purchased from CNOOC Changzhou Environmental Protection Coatings Co., Ltd., the model is BYK-190;

[0049] The defoamer was purchased from CNOOC Changzhou Environmental P...

Embodiment 3a

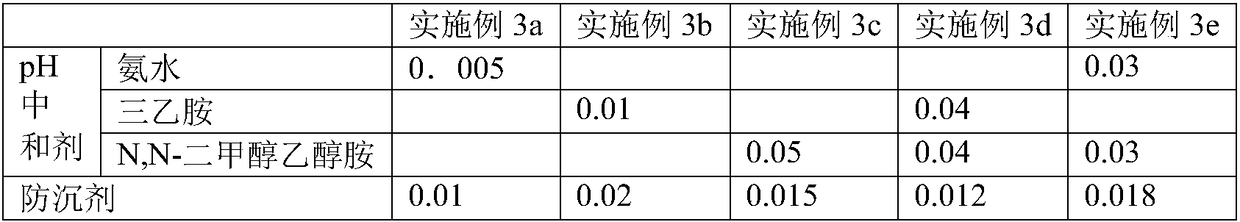

[0066] The difference between embodiment 3a and embodiment 2a is that embodiment 3a also adds the pH neutralizer of 0.005kg and the anti-settling agent of 0.01kg in Step2, and the anti-settling agent is organic bentonite and fumed silica according to the mass ratio of 1:1 composite. The pH neutralizer is ammonia water.

[0067] The preparation method of embodiment 3b-embodiment 3e is the same as that of embodiment 3a, and the only difference is that the specific components and parameters of the pH neutralizer and the specific component parameters of the anti-settling agent are different. The specific results are shown in the table below (unit: kg):

[0068]

[0069] The primer prepared in Example 2a-Example 2e is sprayed on the wall connecting piece disclosed in Example 1, and the wall connecting piece is degreased and phosphated before spraying; the sprayed wall connecting piece is baked at 80°C until solidified After the temperature reaches 30%, spray UV-curable acrylic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com