Low temperature-resistant glufosinate-glyphosate water aqua

A technology of glyphosate water agent and glufosinate-ammonium, which is applied in the field of glufosinate-glyphosate water agent, can solve the problems of reduced control effect, failure to solve the problem of antifreeze, and failure to solve the problem of antifreeze of the composition, so as to reduce storage The effect of low cost and good low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 146

[0024] Embodiment 1 46% glufosinate-ammonium-glyphosate aqueous solution

[0025] Glufosinate-ammonium 5%, Glyphosate Isopropylamine Salt 41%, Alkyl Glycoside 6%, Tallow Amine Polyoxyethylene Ether 6%, Sorbitol 2%, Glucose 1%, Macrogol 400 2%, Water Top-up 100 %.

[0026] The preparation method is: after dissolving glufosinate-ammonium and glyphosate isopropylamine salt, add alkyl glycoside, tallow amine polyoxyethylene ether, glucose, polyethylene glycol, sorbitol and deionized water into the preparation kettle, and start the mixer , after stirring evenly, it will be obtained after passing the quality inspection, and it will be obtained after passing the quality inspection.

Embodiment 24

[0027] Embodiment 2 40% glufosinate-ammonium glyphosate aqueous solution

[0028] Glufosinate-ammonium 7%, Glyphosate Isopropylamine Salt 33%, Alkyl Glycoside 5%, Tallow Amine Polyoxyethylene Ether 5%, Sorbitol 1.5%, Glucose 1%, Macrogol 400 1.5%, Water Top Up 100 %. The preparation method is the same as in Example 1.

Embodiment 3

[0029] Embodiment 3 50% glufosinate-ammonium-glyphosate aqueous solution

[0030] Glufosinate-ammonium 19%, Glyphosate Isopropylamine Salt 31%, Alkyl Glycoside 7%, Tallow Amine Polyoxyethylene Ether 5%, Sorbitol 2%, Glucose 1.5%, Macrogol 400 2%, Water Top-up 100 %. The preparation method is the same as in Example 1. Comparative example 1 46% glufosinate-glyphosate aqueous solution (CN105394080A embodiment 1 product)

[0031] Glufosinate-ammonium 5%, glyphosate isopropylamine salt 41%, alkyl glycoside 15%, water 39%. The preparation method is the same as in Example 1.

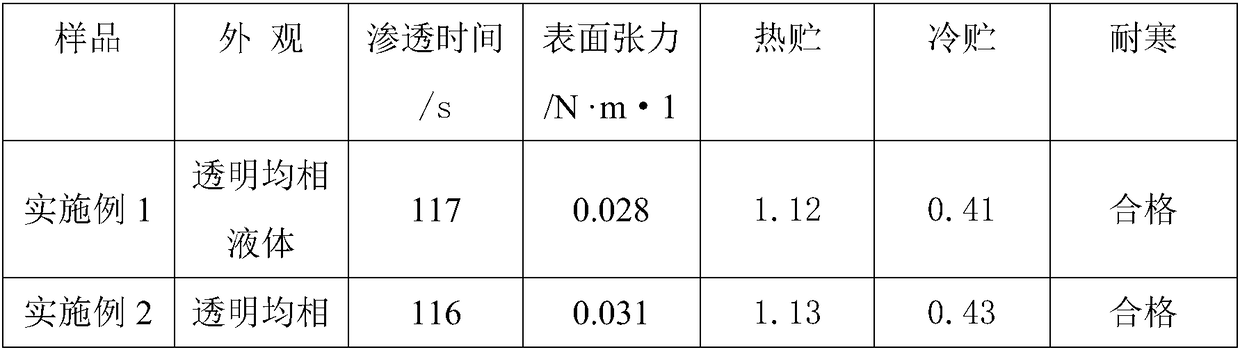

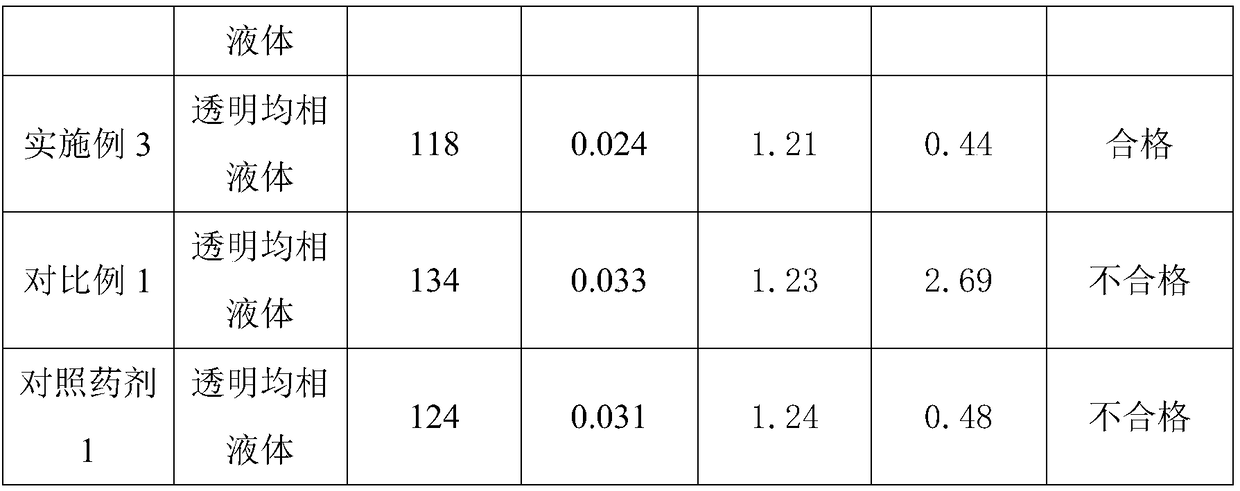

[0032] 2. The overall quality control index of the product

[0033] For the prepared glufosinate-glyphosate aqueous solution and contrast agent 1 (40% glufosinate-glyphosate aqueous solution (30% glyphosate content, 10% glufosinate content), produced by Shaanxi Meibang Pesticide Co., Ltd., The same below) each index (heat storage, cold storage, cold resistance stability, etc.) is tested, and the test resul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com