A kind of seasoning soup block and preparation method thereof

A technology of seasoning soup and dry method, which is applied in food drying, food ingredients containing natural extracts, food science, etc. It can solve the problems of nutrient loss, large equipment footprint, easy loss of amino acids and essential amino acids, etc., and achieve convenience Effect of temperature and humidity, reduction of equipment volume, and large flavor contribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

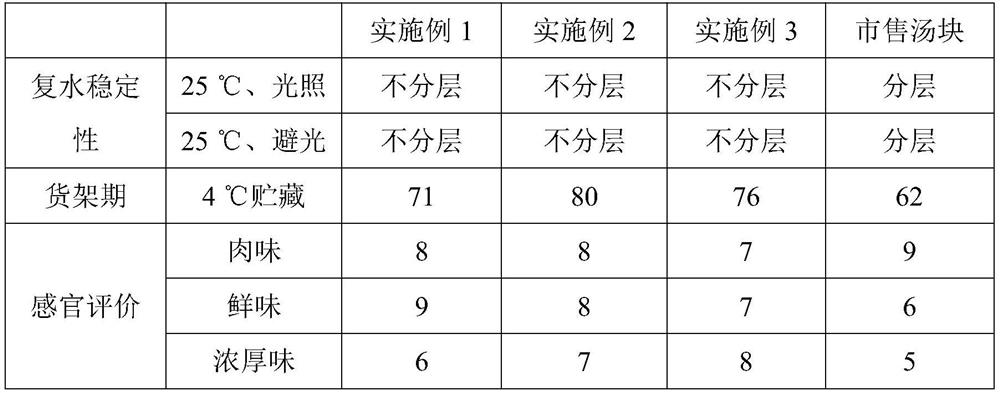

Examples

Embodiment 1

[0052] A seasoning soup cube uses defatted cake powder as a raw material, undergoes enzymatic hydrolysis, and then dissolves through dry Maillard reaction and nano-pulverization treatment, and mixes with spice compound extracts to prepare micellar dry powder, and finally the micellar dry powder It is obtained by mixing with compound fat and solidifying.

[0053] The preparation steps of seasoning soup cube are as follows:

[0054] (1) Preparation of defatted cake powder enzymatic hydrolyzate

[0055] Get 2000g of defatted linseed cake powder with a protein content of 25%, add water and dissolve it to make an aqueous solution of defatted flaxseed meal with a mass concentration of 6%, add alkaline protease 57.1g and transglutaminase 22.9 g g (mass ratio: 5:2) of mixed enzyme A consisting of 80 g in total, and adjust the pH value to 8.0 with 1 mol / L sodium hydroxide solution, the temperature is 30 ° C, and the enzymolysis reaction is 2 h; then add glutamic acid A total of 10 g ...

Embodiment 2

[0074] A seasoning soup cube uses defatted cake powder as a raw material, undergoes enzymatic hydrolysis, and then dissolves through dry Maillard reaction and nano-pulverization treatment, and mixes with spice compound extracts to prepare micellar dry powder, and finally the micellar dry powder It is obtained by mixing with compound fat and solidifying.

[0075] The preparation steps of seasoning soup cube are as follows:

[0076] (1) Preparation of defatted cake powder enzymatic hydrolyzate

[0077] Get the defatted peony seed cake powder 2000g of protein content 50%, add water to dissolve and make the defatted cake powder aqueous solution of mass concentration 12%, add in this aqueous solution by alkaline protease 93.3g and glutamine transaminase 26.7g (mass ratio A total of 120g of mixed enzyme A composed of 7:2) was used to adjust the pH value to 9.0 with 1mol / L sodium hydroxide solution, the temperature was 45°C, and the enzymolysis reaction was 3h; then 12g of transglut...

Embodiment 3

[0096] A seasoning soup cube uses defatted cake powder as a raw material, undergoes enzymatic hydrolysis, and then dissolves through dry Maillard reaction and nano-pulverization treatment, and mixes with spice compound extracts to prepare micellar dry powder, and finally the micellar dry powder It is obtained by mixing with compound fat and solidifying.

[0097] The preparation steps of seasoning soup cube are as follows:

[0098] (1) Preparation of defatted cake powder enzymatic hydrolyzate

[0099] Get the defatted walnut cake powder 1000g that protein content is 45%, the defatted sunflower seed cake powder 1000g that protein content is 37%, add water and dissolve and make the defatted cake flour aqueous solution of mass concentration 10%, in the defatted cake flour aqueous solution Add a total of 100g of mixed enzyme A consisting of 75g of alkaline protease and 25g of transglutaminase (mass ratio: 6:2), adjust the pH value to 8.5 with 1mol / L sodium hydroxide solution, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com