High-purity large-specific-surface platinum black and preparation method thereof

A technology with high specific surface area and specific surface area, which is applied in the field of preparation of platinum black for fuel cells, and can solve problems such as purity and specific surface area that are not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

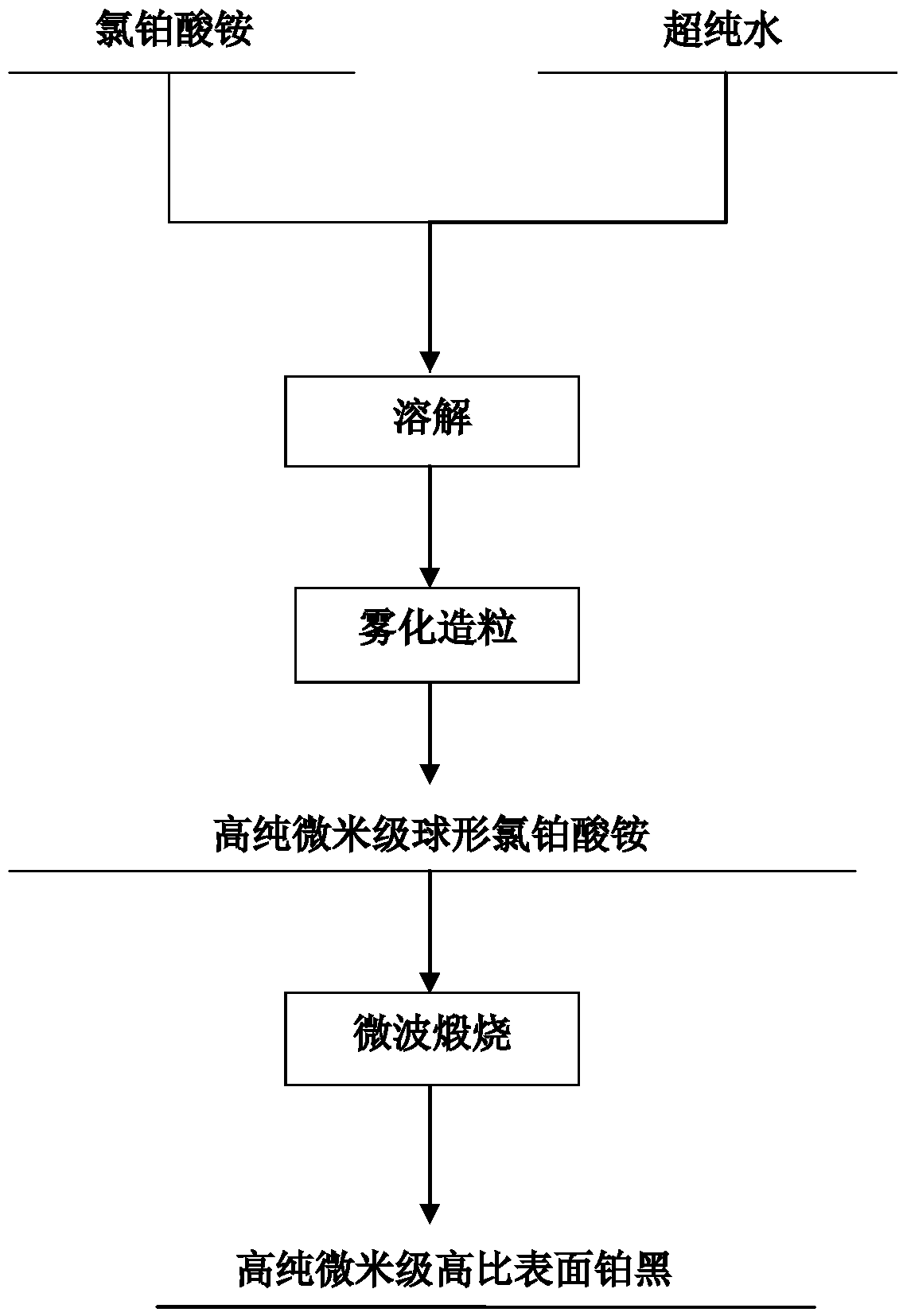

Method used

Image

Examples

Embodiment 1

[0020] The high-purity spherical ruthenium powder of the present invention is obtained through the following steps:

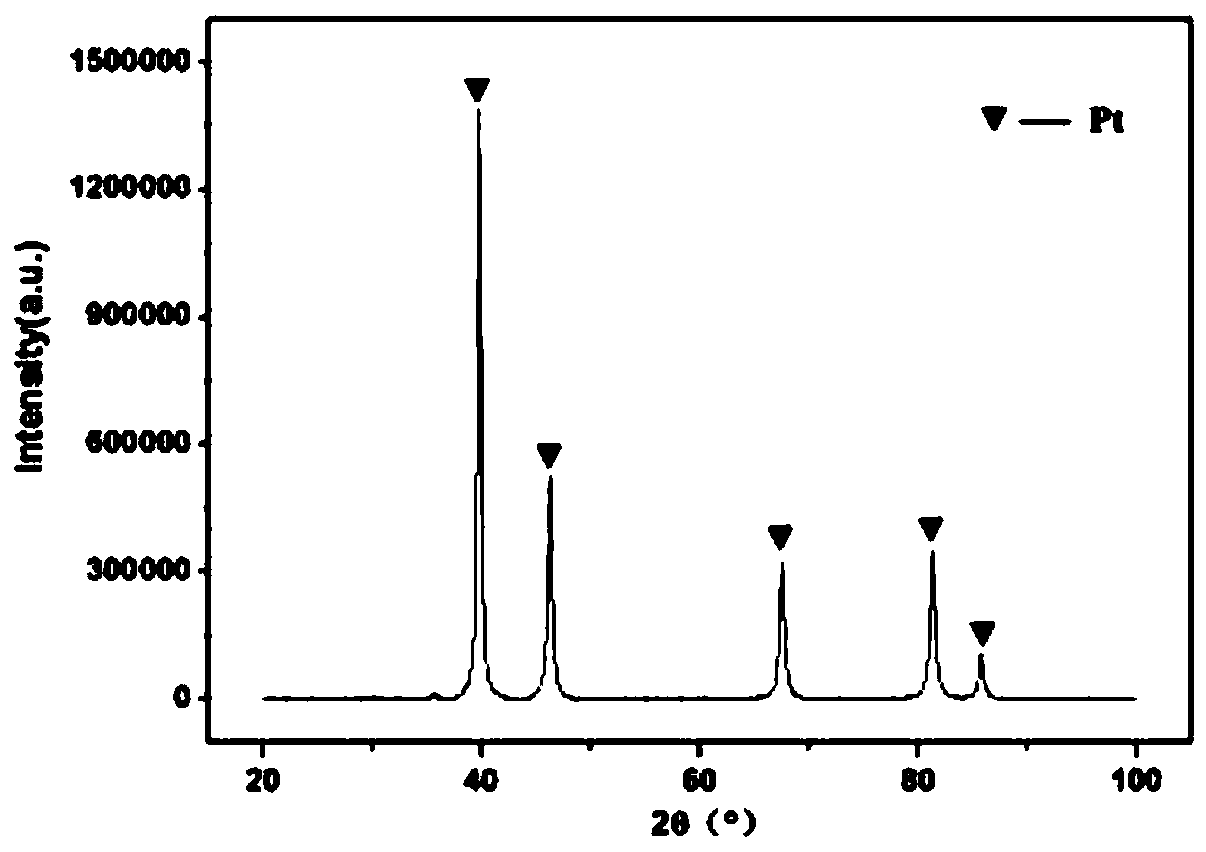

[0021] (1) Atomization drying process: with high purity (NH 4 ) 2 PtCl 6 Powder is used as raw material, the control liquid flow rate is 6.0 mL / min, the atomization pressure is 0.3MPa, the inlet temperature is 200°C, the hot air flow rate is 7.0L / min, the solution concentration is 0.2mol / l, and the high-purity (NH 4 ) 2 PtCl 6 Spherical particles, particle size is about 0.5 ~ 4μm; (2) microwave calcination process: the high-purity spherical (NH 4 ) 2 PtCl 6 The particles are calcined in two stages in a microwave oven. In the first stage, under the protection of nitrogen, the heating rate is 10°C / min, the temperature is raised to 470°C, kept for 3 hours, and cooled with the furnace; the second stage is hydrogen reduction, under the condition of hydrogen, The heating rate is 15°C / min, the temperature is raised to 600°C, kept for 1h, and cooled with the fur...

Embodiment 2

[0023] The difference from Example 1 is that the atomization and granulation process is as follows: the flow rate of the control liquid is 8.0 mL / min, the atomization pressure is 0.5 MPa, the inlet temperature is 220° C., and the flow rate of hot air is 10.0 L / min. The microwave calcination process is as follows: in the first stage, the temperature is raised from room temperature to 470° C. for 2 hours, and in the second stage, the temperature is raised to 600° C. for 2 hours, and then cooled with the furnace.

Embodiment 3

[0025] The difference from Example 1 is that the atomization and granulation process is as follows: the flow rate of the control liquid is 3.0 mL / min, the atomization pressure is 0.4 MPa, the inlet temperature is 160° C., and the flow rate of hot air is 4.0 L / min. The microwave calcination process is as follows: in the first stage, the temperature is raised from room temperature to 450° C. for 2 hours, and in the second stage, the temperature is raised to 550° C. for 2 hours, and then cooled with the furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com