Production method of high temperature covering agent grade boron oxide

A production method and technology of boron oxide, applied in boron oxides, boron oxide compounds, etc., can solve problems such as high vacuum degree is not easy to obtain, small output, unfavorable stable production and product quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

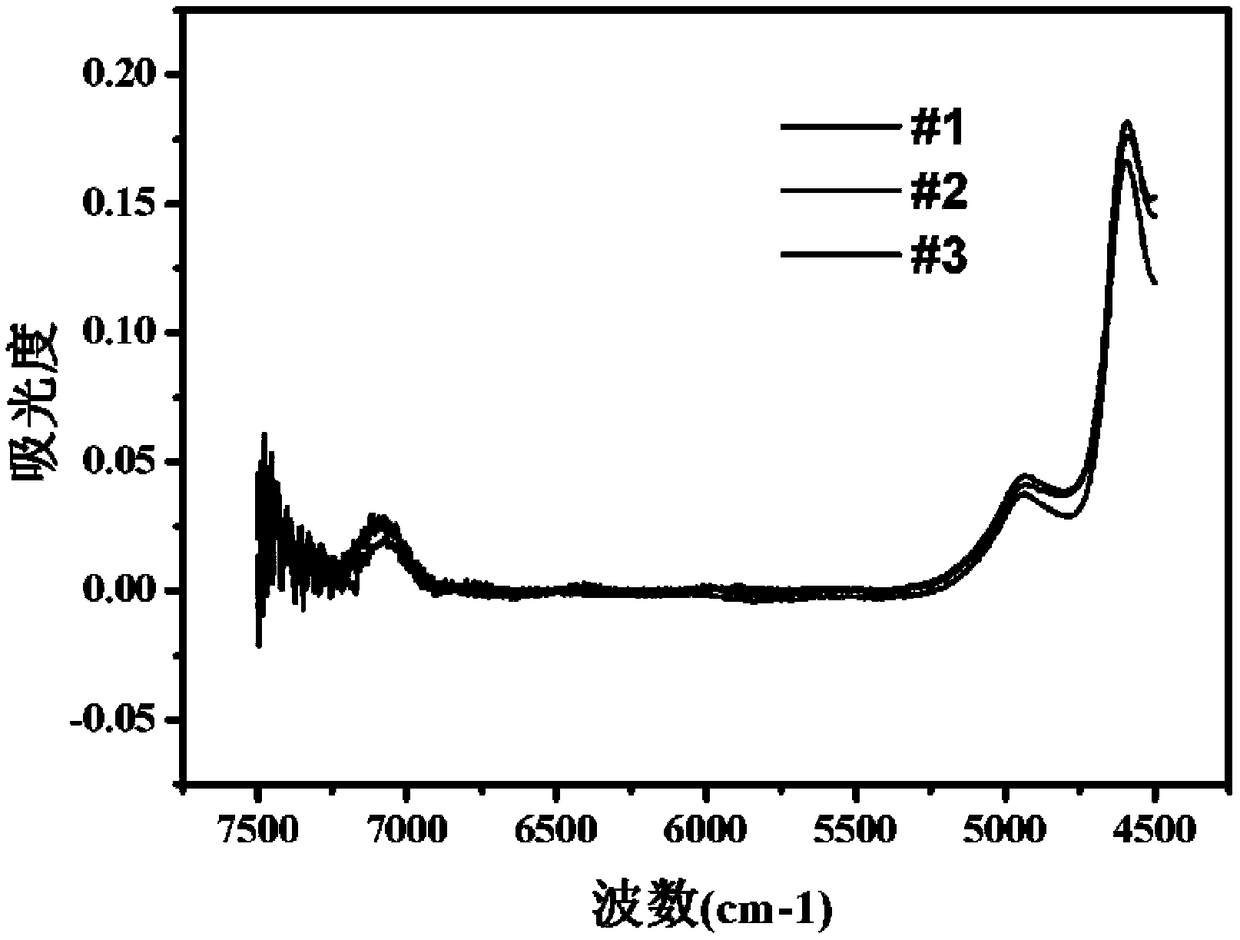

Image

Examples

Embodiment 1

[0027] Dry 400g of boric acid powder with a purity of 5N at 100°C for 24 hours or more in advance, then divide it into two batches and put them into platinum crucibles, adjust the heating power of the intermediate frequency furnace, heat the boric acid to 600°C, and feed the two batches at an interval of 10 minutes . When the boric acid powder in the crucible is all in a transparent molten state and no longer bubbles, put 100g of anhydrous boron oxide with a purity of 5N into it. Adjust the heating power of the intermediate frequency furnace, heat the boron oxide to 900 °C, and calcine for 15 min. Connect the vacuum system, turn on the vacuum switch, turn the valve to 1 / 3, and adjust the induction heating power to the set value. Observe the boiling of the melt, and control the splashing of the melt by controlling the tightness of the bottom valve. Pump the vacuum of the intermediate frequency furnace to below 50 Pa within 40 min, tighten the bottom valve, and continue vacuum...

Embodiment 2

[0029] Dry 500 g of boric acid powder with a purity of 5N at 100°C for 24 hours or more in advance, divide it into two batches and put it into a platinum crucible, adjust the heating power of the intermediate frequency furnace, heat the boric acid to 700°C, and feed the two batches at an interval of 20 minutes . When the boric acid powder in the crucible is all in a transparent molten state and no longer bubbles, put 200g of anhydrous boron oxide with a purity of 5N into it. Adjust the heating power of the intermediate frequency furnace, heat the boron oxide to 950 °C, and calcine for 30 min. Connect the vacuum system, turn on the vacuum switch, turn the valve to 1 / 4, and adjust the induction heating power to the set value. Observe the boiling of the melt, and control the splashing of the melt by controlling the tightness of the bottom valve. Pump the vacuum of the intermediate frequency furnace to below 50 Pa within 50 minutes, tighten the bottom valve, and continue vacuum ...

Embodiment 3

[0031] Dry 600 g of boric acid powder with a purity of 5N at 100°C for 24 hours or more in advance, and then divide it into two batches and put them into platinum crucibles. Adjust the heating power of the intermediate frequency furnace to heat the boric acid to 800°C. 30min. When the boric acid powder in the crucible is all in a transparent molten state and no longer bubbles, drop 300g of anhydrous boron oxide with a purity of 5N into it. Adjust the heating power of the intermediate frequency furnace to heat boron oxide to 1000 °C for 20 min. Connect the vacuum system, turn on the vacuum switch, turn the valve to 1 / 2, and adjust the induction heating power to the set value. Observe the boiling of the melt, and control the splashing of the melt by controlling the tightness of the bottom valve. Pump the vacuum of the intermediate frequency furnace to below 50 Pa within 40 min, tighten the bottom valve, and continue vacuum dehydration for 150 min. Keep the heating power const...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com