Injecting decreasing recycling method for water produced in gas field

A technology for producing water and gas fields, applied in chemical instruments and methods, water/sewage treatment, mining wastewater treatment, etc., can solve problems such as reducing the amount of wastewater reinjection, to ensure long-term stable operation, improve removal effect, and maintain operation and maintenance easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

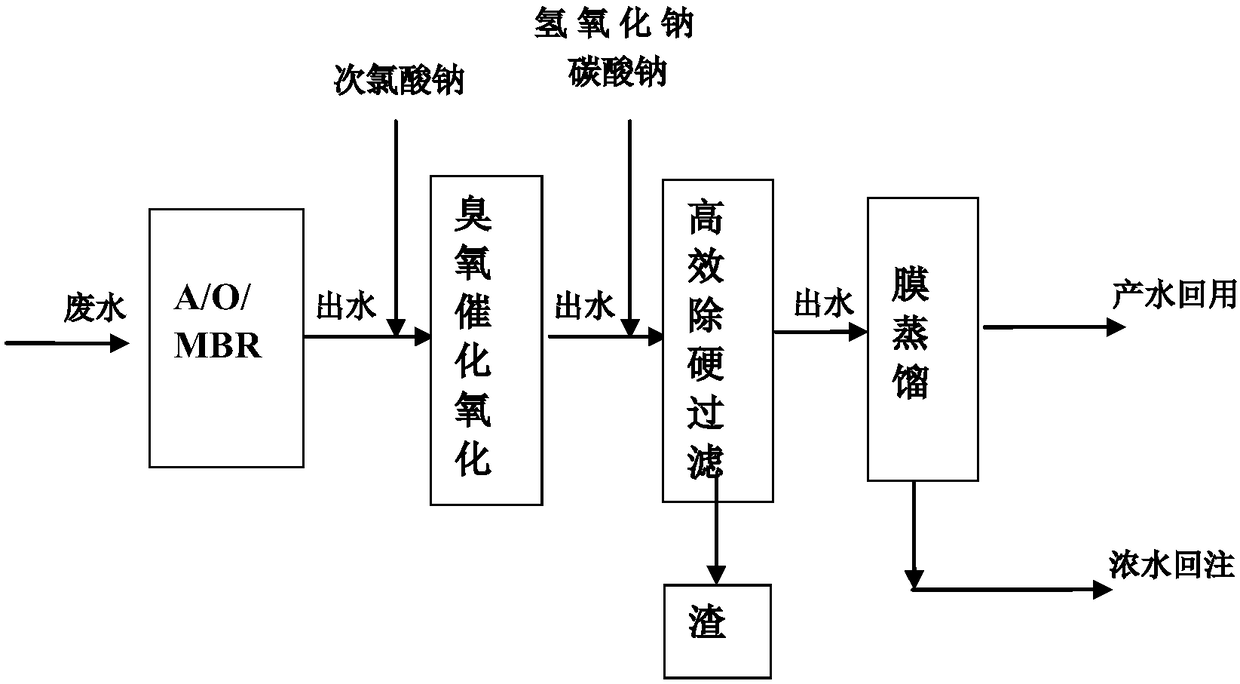

Method used

Image

Examples

Embodiment 1

[0061] The main water quality characteristics of the produced water of a certain gas field are: influent pH 7, total dissolved solids 10000mg / L, suspended solids 300mg / L, oil content 5mg / L, ammonia nitrogen 50mg / L, total hardness (CaCO 3 meter) 800mg / L, total alkalinity (CaCO 3 Total) 250mg / L, Na + 4000mg / L, Cl - 5000mg / L, SO 4 2- 800mg / L, COD 800mg / L.

[0062] The processing steps are as follows:

[0063] Step 1: The produced water from the gas field enters the A / O / MBR unit sequentially to form the MBR produced water. Among them, the residence time of the anoxic section A is 4h, the total residence time of the aerobic O section and the MBR membrane pool is 27h, the sludge return rate is 300%, the sludge discharge volume is 1%, and the sludge concentration is 10g / L;

[0064] Under these conditions, the MBR membrane flux is controlled at 12L / m 2 h; COD of MBR product water is about 200mg / L, ammonia nitrogen is about 28mg / L;

[0065] Step 2, the MBR product water enters ...

Embodiment 2

[0073] The main water quality characteristics of the produced water of a certain gas field are: influent pH 7.5, total dissolved solids 16000mg / L, suspended solids 700mg / L, oil content 10mg / L, ammonia nitrogen 120mg / L, total hardness (CaCO 3 meter) 1200mg / L, total alkalinity (CaCO 3 Total) 500mg / L, Na + 7000mg / L, Cl - 9000mg / L, SO 4 2- 1100mg / L, COD 1300mg / L.

[0074] The processing steps are as follows:

[0075] Step 1: The produced water from the gas field enters the A / O / MBR unit sequentially to form the MBR produced water. Among them, the residence time of anoxic section A is 5h, the total residence time of aerobic O section and MBR membrane pool is 30h, the sludge return rate is 350%, the sludge discharge volume is 1.5%, and the sludge concentration is 11g / L;

[0076] Under these conditions, the MBR membrane flux is controlled at 11L / m 2 h; COD of MBR product water is about 280mg / L, ammonia nitrogen is about 65mg / L;

[0077] Step 2: Before the MBR product water ent...

Embodiment 3

[0085] The main water quality characteristics of gas field produced water are: influent pH 8, total dissolved solids 22000mg / L, suspended solids 1500mg / L, oil content 20mg / L, ammonia nitrogen 250mg / L, total hardness (CaCO 3 meter) 1800mg / L, total alkalinity (CaCO 3 Total) 750mg / L, Na + 10000mg / L, Cl - 12000mg / L, SO 4 2- 1500mg / L, COD 1500mg / L.

[0086] The processing steps are as follows:

[0087] Step 1: The produced water from the gas field enters the A / O / MBR unit sequentially to form the MBR produced water. Among them, the residence time of the anoxic section A is 6h, the total residence time of the aerobic O section and the MBR membrane pool is 32h, the sludge return rate is 400%, the sludge discharge volume is 2%, and the sludge concentration is 12g / L;

[0088] Under these conditions, the MBR membrane flux is controlled at 12L / m 2 h; COD of MBR product water is about 360mg / L, ammonia nitrogen is about 110mg / L;

[0089] Step 2, before the MBR product water enters t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com