Production method of stone protective agent

A production method and technology of protective agent, which are applied in the preparation of stone protective agent and the field of stone protective agent, can solve the problems of uneven varieties, different use costs, uneven protective effects, etc., and achieve good surface hydrophobicity and water contact. Corner raising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

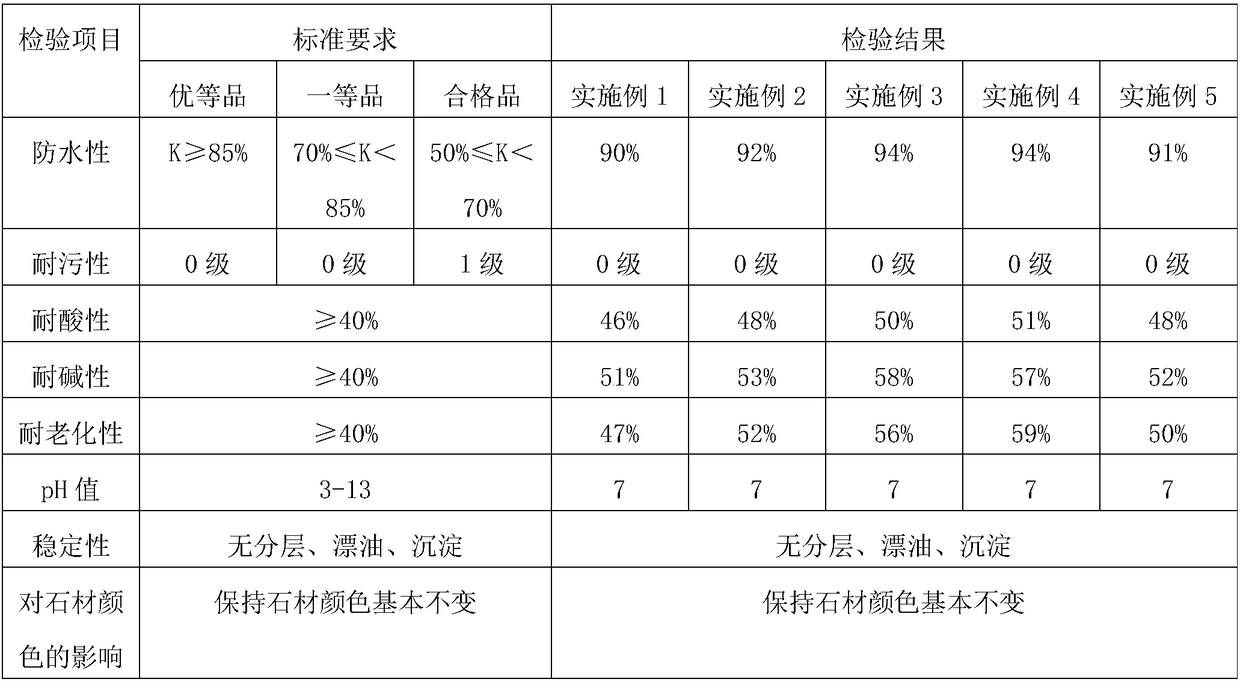

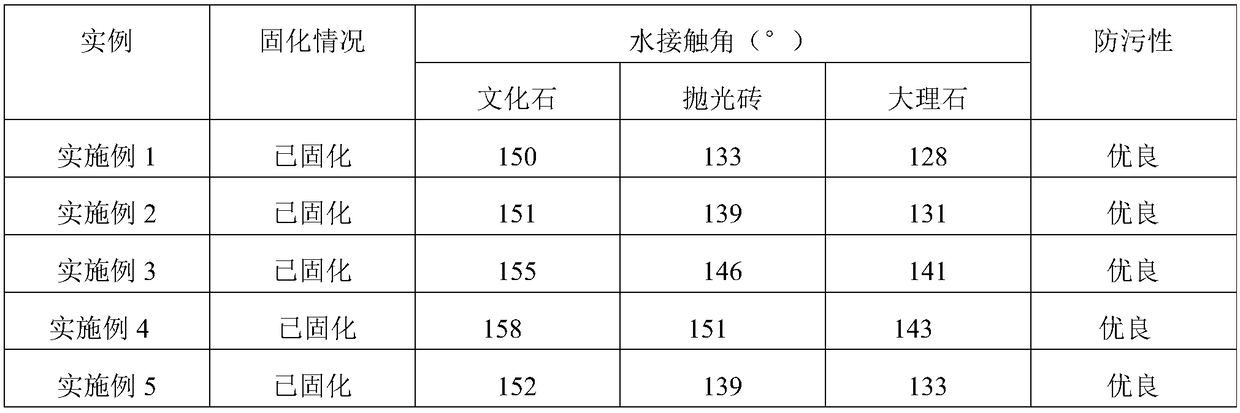

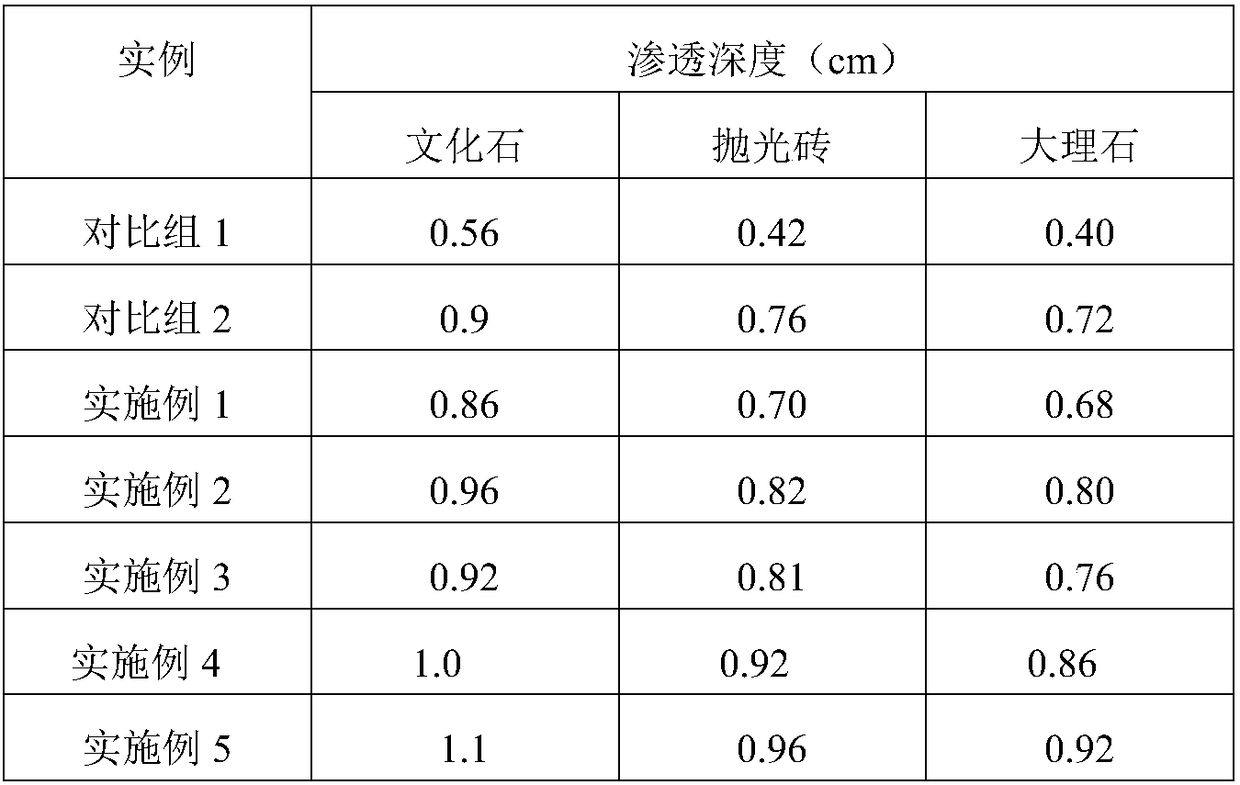

Examples

Embodiment 1

[0031] A production method of stone protective agent, comprising the following steps: in parts by weight, 10 parts of hydroxy silicone oil with a viscosity of 20 mm2 / s, 30 parts of hydroxy silicone oil with a viscosity of 65 mm2 / s, and 10 parts of dodecyl triethoxy silane , 0.3 parts of tetramethylammonium hydroxide catalyst and 48 parts of ethanol were put into the reaction kettle, heated at 80℃ for 2.5 hours, then cooled, and 1.7 parts of acetic acid were added until neutralization, to obtain an active silicon-containing hydroxyl bond The long-chain alkyl-modified polysiloxane; then take 2 parts of the long-chain alkyl-modified polysiloxane containing active silicon hydroxyl bonds, add 5 parts of hydrogen-containing silicone oil with a hydrogen content of 0.2wt%, and add 18 A mixed solvent composed of 120 parts gasoline and 72 parts ethanol, 2.8 parts of 0.5 μm nano-silica and 0.2 parts of tetrabutyl titanate catalyst are added and mixed uniformly to obtain a stone protective ...

Embodiment 2

[0033] A production method of stone protective agent, including the following steps: in parts by weight, 12.5 parts of hydroxy silicone oil with a viscosity of 25mm2 / s, 37.5 parts of hydroxy silicone oil with a viscosity of 60mm2 / s, and 15 parts of tridecafluorooctyltrimethoxysilane , 0.3 parts of tetramethyl ammonium hydroxide catalyst and 33.7 parts of ethanol were put into the reaction kettle, heated at 80℃ for 3 hours, then cooled, and 1 part of acetic acid was added until neutralization to obtain active silicon hydroxyl bond The long-chain alkyl-modified polysiloxane; then 4.5 parts of the long-chain alkyl-modified polysiloxane containing active silicon hydroxy bonds are added to 3.2 parts of hydrogen-containing silicone oil with a hydrogen content of 0.3wt% and 0.8 parts Hydrogen-containing silicone oil with a hydrogen content of 1.1wt%, adding 15 parts of 120# gasoline and 72.8 parts of ethanol mixed solvent, then adding 3.5 parts of 0.8μm nano diatomaceous earth and 0.2 ...

Embodiment 3

[0035] A production method of stone protective agent, comprising the following steps: in parts by weight, 14 parts of hydroxy silicone oil with a viscosity of 25 mm2 / s, 42 parts of hydroxy silicone oil with a viscosity of 75 mm2 / s, and 15 parts of heptafluorodecyl triethoxy Silane, 0.2 parts of potassium hydroxide catalyst, and 28.3 parts of ethanol were put into the reaction kettle, heated at 80°C for 3 hours, then cooled, and 0.5 part of acetic acid was added until it was neutralized to obtain a long chain containing active silicon hydroxyl bonds. Alkyl-modified polysiloxane; then take 6 parts of long-chain alkyl-modified polysiloxane with active silicon hydroxyl bond, add 1 part of hydrogen-containing silicone oil with hydrogen content of 0.2wt%, and 1 part of hydrogen-containing silicone oil A mixture of 0.4wt% hydrogen-containing silicone oil and 1 part hydrogen-containing silicone oil with a hydrogen content of 1.1wt%, adding 18 parts of 120# gasoline, 20 parts of ethanol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com