Method for preparing crude ganoderma lucidum spore powder wall shell polysaccharide through irradiation

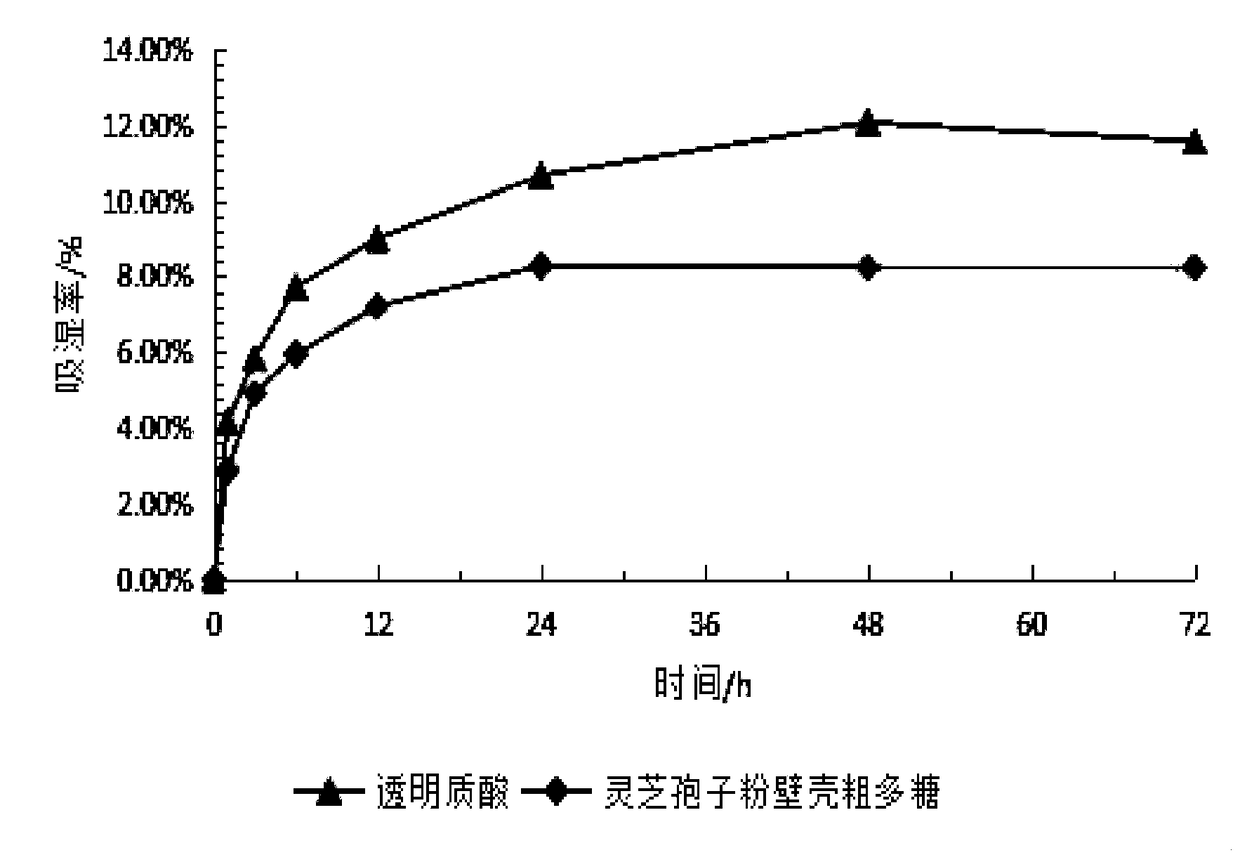

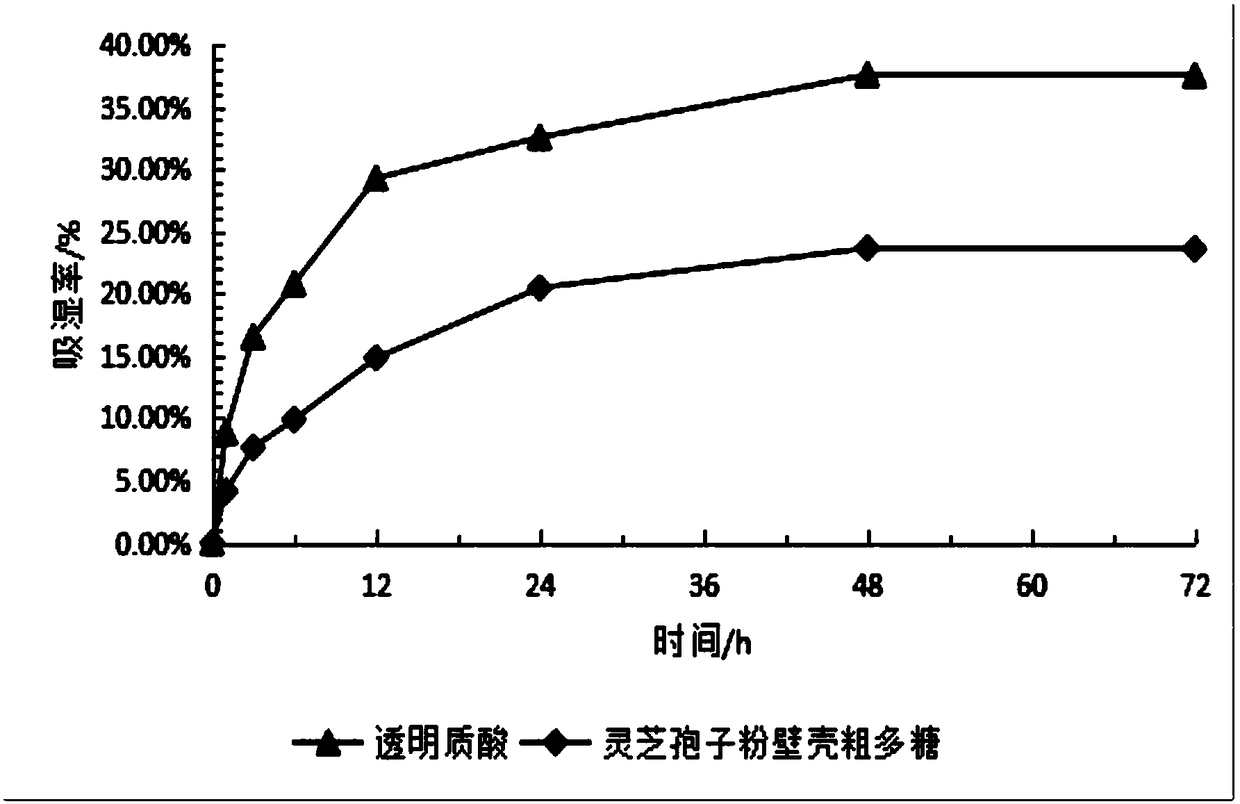

A technology of Ganoderma lucidum spore powder and crude polysaccharide, which is applied in the field of extracting effective substances of fungi, can solve the problems such as difficulty in obtaining effective substances, and achieve excellent immune regulation function, moisturizing effect, and excellent moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

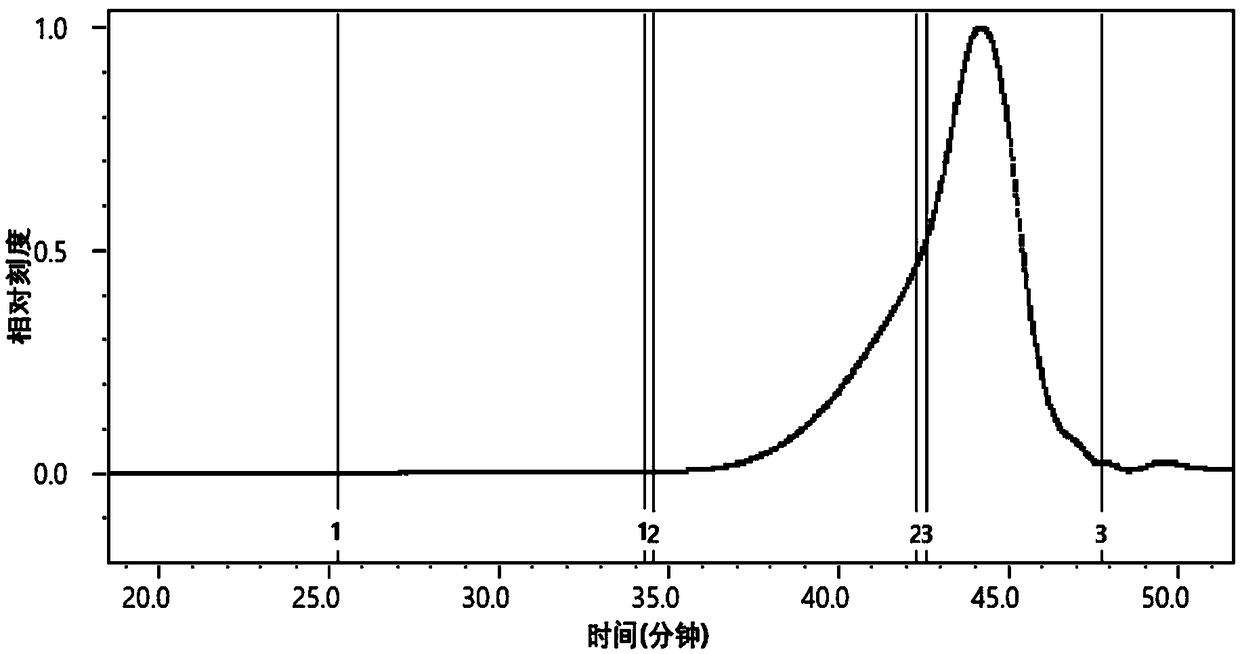

[0045] Composition determination of embodiment 1 Ganoderma lucidum spore powder wall shell waste

[0046] 1. Determination of moisture and ash content: Take samples No. 1 and No. 2 respectively, and conduct moisture determination according to GB / T 12531-1990 Moisture Standard for Edible Fungi, and measure ash content according to GB 12532-1990 Determination Standard for Ash Content of Edible Fungi.

[0047] The results showed that the moisture contents of samples No. 1 and No. 2 were 8.20%, 14.8%, and the ash contents were 0.99%, 1.04%, respectively.

[0048] 2. Determination of protein and amino acid content: Samples No. 1 and No. 2 were taken respectively, and the protein content was determined according to the GB 5009.5-2010 method, and the amino acid content was determined according to the GB / T 5009.124-2003 method.

[0049] The results showed that the total protein contents of No. 1 and No. 2 samples were 24.58% and 23.08%, and the contents of amino acids were 7.04% and 6...

Embodiment 2

[0058] This experiment verified the effect of irradiation treatment on polysaccharide content

[0059] Take 500g of sample No. 1 and sample No. 2 respectively, and irradiate them with electron beams to a dose of 500kGy to obtain irradiated waste;

[0060] The polysaccharide content was measured by the phenol-sulfuric acid method, and the specific operation was the same as the polysaccharide content determination step in Example 1. The measurement results showed that the polysaccharide content in the irradiated waste prepared by No. 1 sample and No. 2 sample was 7.78% and 6.38% respectively. %.

[0061] As can be seen from the results, after the extraction waste of ganoderma lucidum spore powder was irradiated, the water-soluble polysaccharide content therein was significantly improved. Compared with the polysaccharide content measured in Example 1, the irradiated waste in the irradiation waste The polysaccharide content is increased by more than 8 times, which is more than 3 ...

Embodiment 3

[0063] Weigh 500 g of sample No. 1 of Ganoderma lucidum spore powder extraction waste, and irradiate it with an electron beam to a dose of 500 kGy to obtain irradiated waste. Mix 100g of irradiated waste with 4L of distilled water, extract at 100°C for 2 hours, centrifuge, and filter to obtain the supernatant, which is the crude polysaccharide extract.

[0064] Concentrate the obtained crude polysaccharide extract under reduced pressure to 0.1L at 100mbar and 50°C, freeze the concentrated liquid at -20°C for 2 hours, then freeze at -80°C for 3 hours, and put it in a freeze dryer Freeze-drying to obtain 7.03 g of crude polysaccharide of ganoderma lucidum spore powder.

[0065] The polysaccharide content of the prepared Ganoderma lucidum spore powder wall shell crude polysaccharide was determined, and the method was as described in Example 1. The results showed that the active polysaccharide content was 78.59%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com