Method for producing terephthalic unsaturated polyester resin by using waste terephthalic acid

A technology for waste terephthalic acid and terephthalic acid, which is applied in the field of producing terephthalic unsaturated polyester resins with waste terephthalic acid, can solve the problems of high price of purified terephthalic acid and the like, and achieves improved hardness, The effect of reducing production costs and improving gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

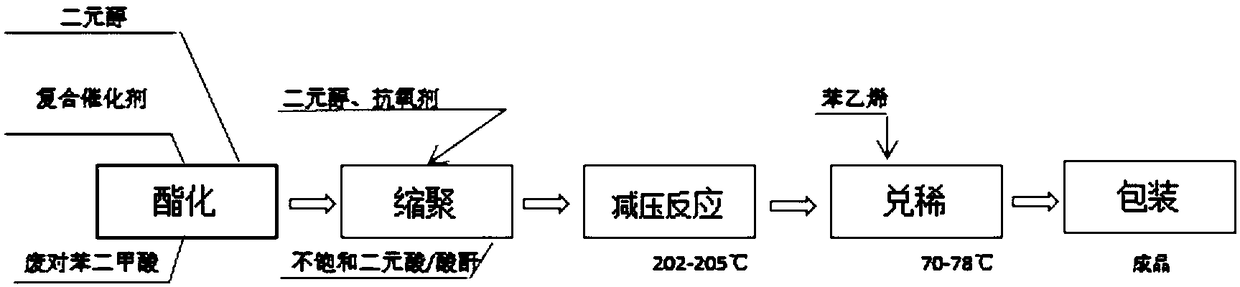

Method used

Image

Examples

Embodiment 1

[0028] (1) Put 4400kg of waste terephthalic acid into 4200kg of diethylene glycol and 1400kg of ethylene glycol, and heat up to 120°C;

[0029] (2) Under the protection of nitrogen, add 8kg of composite catalyst, heat up to 190°C for esterification reaction, until the acid value of the system is lower than 10mgKOH / g; the composite catalyst is stannous oxide, dibutyl A mixture of base tin oxide and zinc acetate;

[0030] (3) When the temperature is lowered to 160°C, add 1400kg propylene glycol, 2.5kg triphenyl phosphite, 3000kg maleic anhydride and 2000kg fumaric acid, and heat up to 185°C for polycondensation until the acid value of the system is lower than 60mgKOH / g;

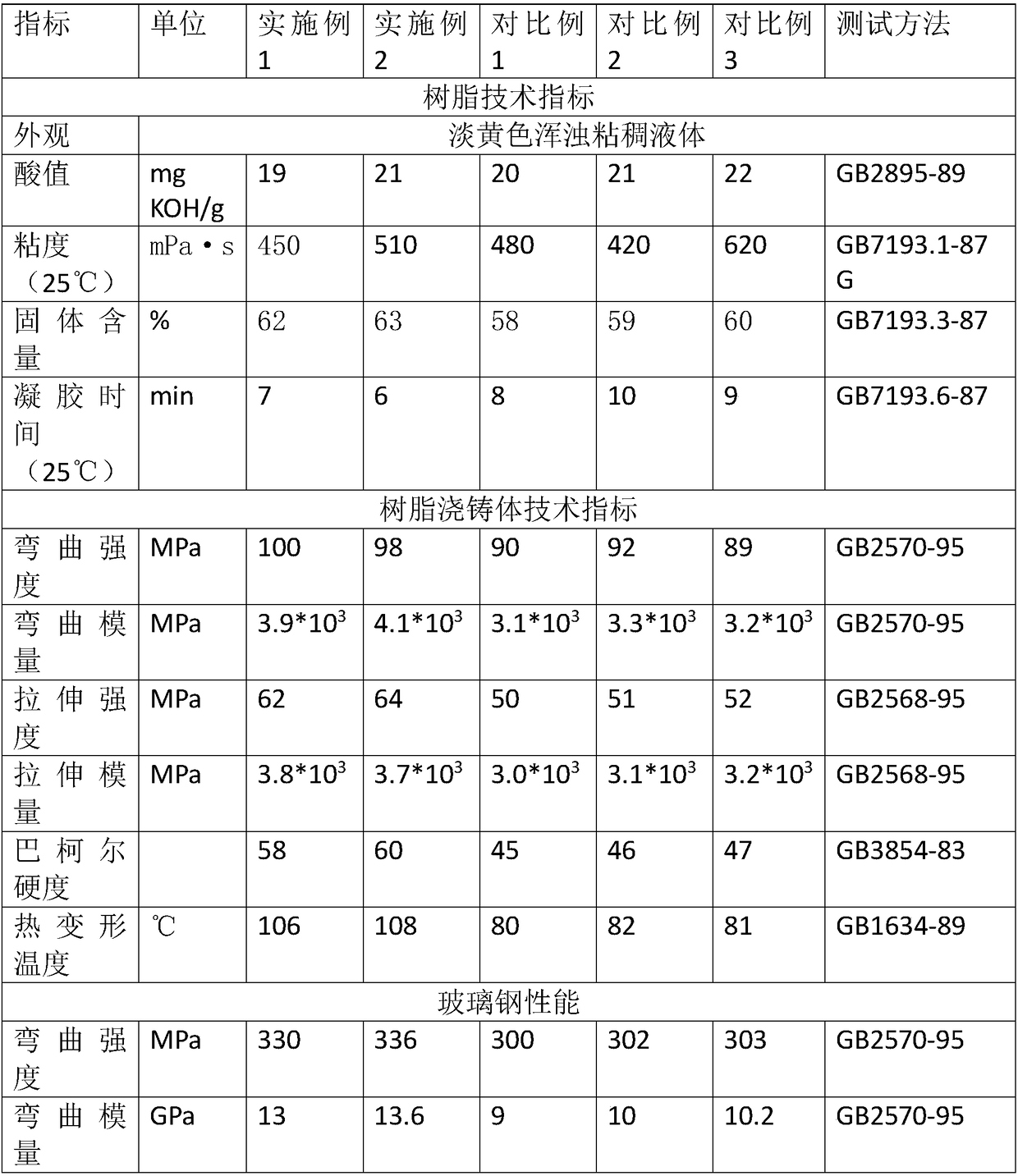

[0031] (4) At 202-205°C, depressurize and react until the acid value of the system is lower than 40mgKOH / g, cool down to 150°C and dilute, add 6700kg of styrene at 70-78°C, stir for 60-70 minutes, and react When the acid value of the system is 18-23 mgKOH / g, the p-phenylene type unsaturated polyester resin c...

Embodiment 2

[0034] (1) Put 4400kg of waste terephthalic acid into 4200kg of diethylene glycol and 1400kg of ethylene glycol, and heat up to 120°C;

[0035] (2) Under the protection of nitrogen, add 8kg of composite catalyst, heat up to 190°C for esterification reaction, until the acid value of the system is lower than 10mgKOH / g; the composite catalyst is stannous oxide, dibutyl A mixture of base tin oxide and zinc acetate;

[0036] (3) When the temperature is lowered to 160°C, add 1400kg propylene glycol, 2.5kg triphenyl phosphite, 3000kg maleic anhydride and 2000kg fumaric acid, and heat up to 185°C for polycondensation until the acid value of the system is lower than 60mgKOH / g;

[0037] (4) At 202-205°C, depressurize and react until the acid value of the system is lower than 40mgKOH / g, cool down to 150°C and dilute, add 6700kg of styrene at 70-78°C, stir for 60-70 minutes, and react When the acid value of the system is 18-23 mgKOH / g, the p-phenylene type unsaturated polyester resin c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com