Preparation method for extracting high-quality protein peptide from pig lung

A protein peptide and high-quality technology, applied in the biological field, can solve problems such as waste of biological resources, food safety issues, and waste of discarding, and achieve the effects of short production cycle, low cost, and high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

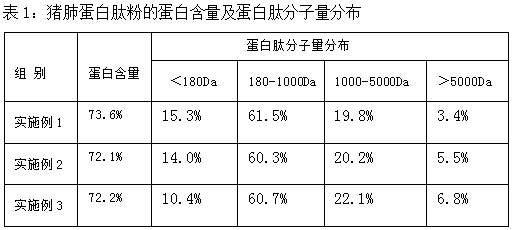

Embodiment 1

[0020] (1) Beating: take 100 kg of fresh pig lungs, wash and decontaminate, peel off the trachea, and remove grease, grind them into minced meat with a chopping machine, and then grind and homogenize them with a fine grinder for 5 minutes to obtain pig lung slurry ;

[0021] (2) Degreasing: add 300 kg of water to the lung slurry, stir and mix, adjust the pH value to 8.5, raise the temperature to 43-45°C, add 120 grams of lipase, keep it warm for 60 minutes, and then pass through 100 Mesh filter, collect filter residue;

[0022] (3) Enzymolysis: Add water twice its weight to the collected filter residue, stir evenly, adjust the pH value to 8.8, add 2.5 grams of alkaline protease per kilogram of filter residue, heat to 42-45°C, and keep warm for 9 hours , heat the enzymolysis solution to 85°C to inactivate the enzyme for 10 minutes to obtain the enzymolysis solution;

[0023] (4) Ultrafiltration: The enzymatic hydrolysis solution is subjected to ultrafiltration through an ultr...

Embodiment 2

[0027] (1) Beating: Take 500 kg of frozen pig lungs, wash and decontaminate after natural thawing, peel off the trachea, remove the grease, then use a chopping machine to grind into minced meat, and then grind and homogenize it with a fine grinder for 10 minutes to obtain pig lungs slurry;

[0028] (2) Degreasing: Add 1,000 kg of water to the lung slurry, stir and mix, adjust the pH to 8.8, raise the temperature to 43-45°C, add 1,200 grams of lipase, keep it warm for 45 minutes, and then pass through 100 Mesh filter, collect filter residue;

[0029] (3) Enzymolysis: Add water three times its weight to the collected filter residue, stir evenly, adjust the pH value to 8.5, add 3.5 grams of alkaline protease per kilogram of filter residue, heat to 45-48°C, and keep warm for 7 hours , heat the enzymolysis solution to 85°C to inactivate the enzyme for 10 minutes to obtain the enzymolysis solution;

[0030] (4) Ultrafiltration: The enzymatic hydrolysis solution is subjected to ult...

Embodiment 3

[0034] (1) Beating: take 1,000 kg of fresh pig lungs, wash and decontaminate, peel off the trachea, and remove grease, grind them into minced meat with a chopping machine, and then grind and homogenize them with a fine grinder for 10 minutes to obtain pig lung slurry ;

[0035] (2) Degreasing: Add 2,500 kg of water to the lung slurry, stir and mix, adjust the pH to 9.0, raise the temperature to 43-45°C, add 2,800 grams of lipase, keep it warm for 50 minutes, and then pass through 100 Mesh filter, collect filter residue;

[0036] (3) Enzymolysis: Add 2.5 times the weight of water to the collected filter residue, stir evenly, adjust the pH value to 8.2, add 4.5 grams of alkaline protease per kilogram of filter residue, heat to 47-50°C, and keep warm for 5 hours , heat the enzymolysis solution to 85°C to inactivate the enzyme for 10 minutes to obtain the enzymolysis solution;

[0037] (4) Ultrafiltration: The enzymatic hydrolysis solution is subjected to ultrafiltration through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com